Ti base shape memory alloy rivet fastening piece and manufacturing method thereof

A memory alloy and manufacturing method technology, applied in rivets and other directions, can solve the problems of difficulty in low temperature machining and deformation of shape memory alloy rivets, achieve excellent performance stability and reliability, solve the difficulty of low temperature machining deformation, and reduce structural weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The composition of Ti-based shape memory alloy rivets is Ti‐(20‐30)Zr.

[0049] Its manufacturing method is as follows:

[0050] 1. Alloy smelting: According to the ratio of alloy composition, select high-purity Ti (purity ≥ 99.99%), high-purity Zr (purity ≥ 99.99%) and other high-purity alloy raw materials with appropriate proportions, and use vacuum non-consumable arc The alloy ingot is obtained by smelting, and the homogenization treatment is carried out by holding the temperature at 1000°C for 14 hours to ensure the uniformity of the alloy composition;

[0051] 2. Alloy forging and drawing: alloy ingots are forged at 920°C to obtain billets of a certain size, and then alloy rods with a diameter of 80mm are obtained through drawing processes;

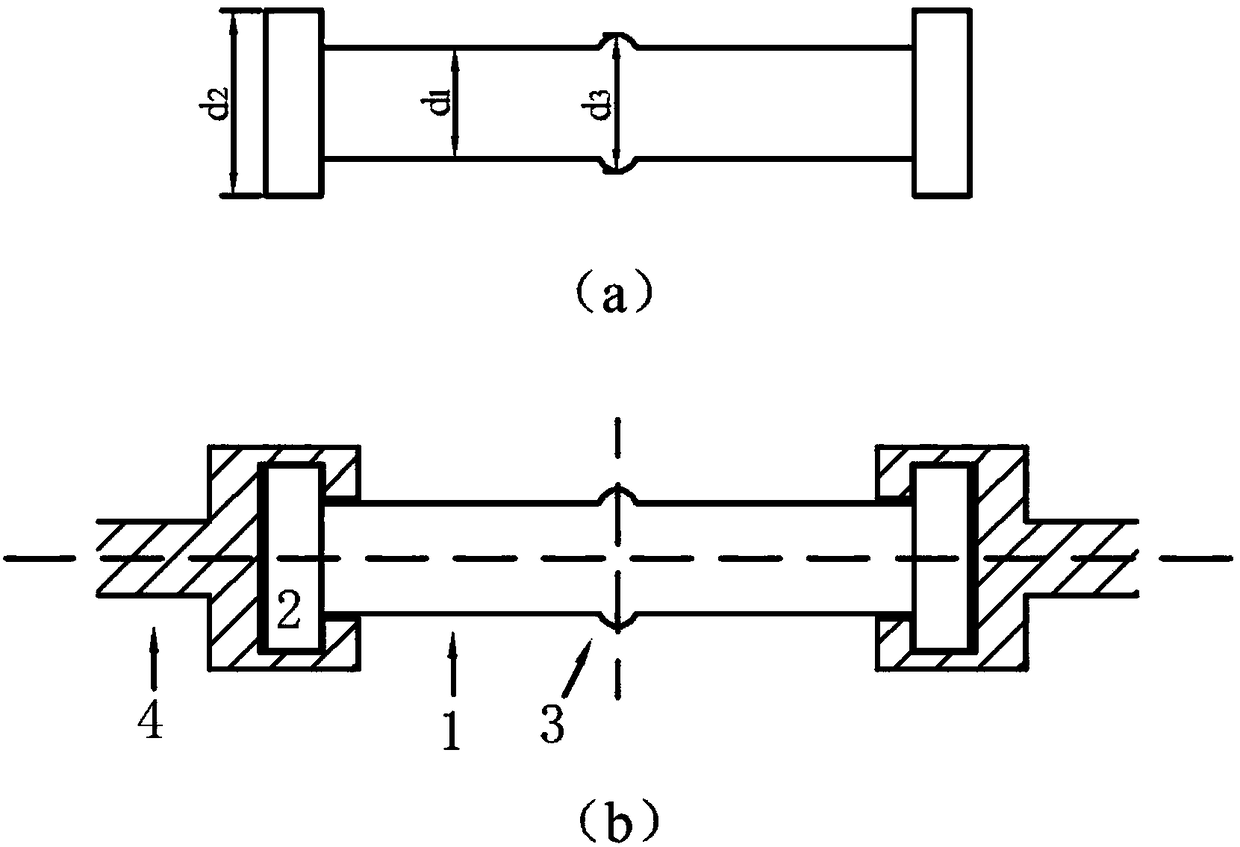

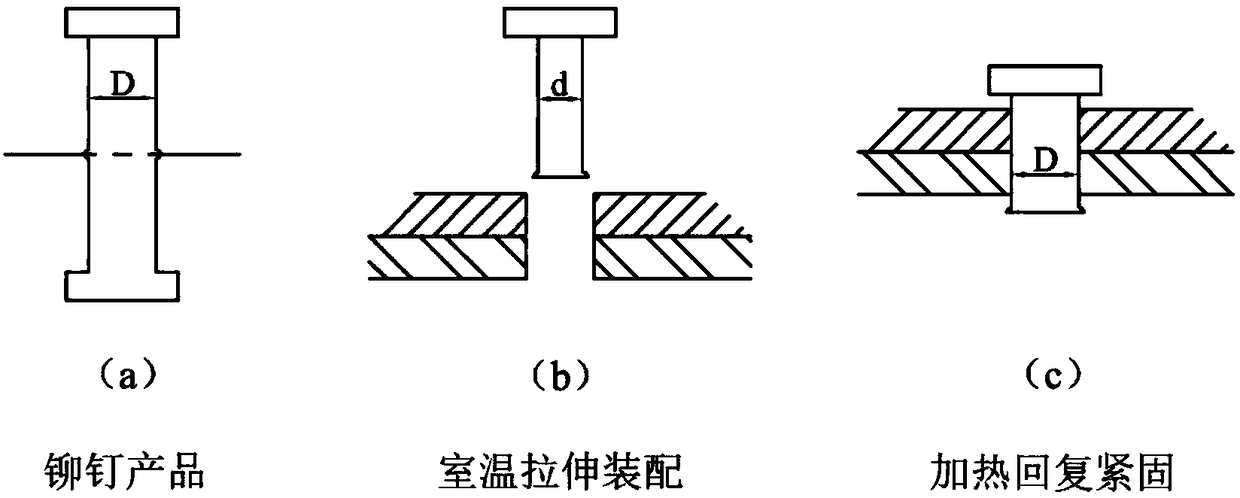

[0052] 3. Mechanical processing: the Ti-based shape memory alloy rod is produced by more than one mechanical processing forming method such as turning, clamping, milling, planing, and grinding. figure 1 The symmetrical struc...

Embodiment 2

[0057] The composition of Ti-based shape memory alloy rivets is Ti‐35Mo.

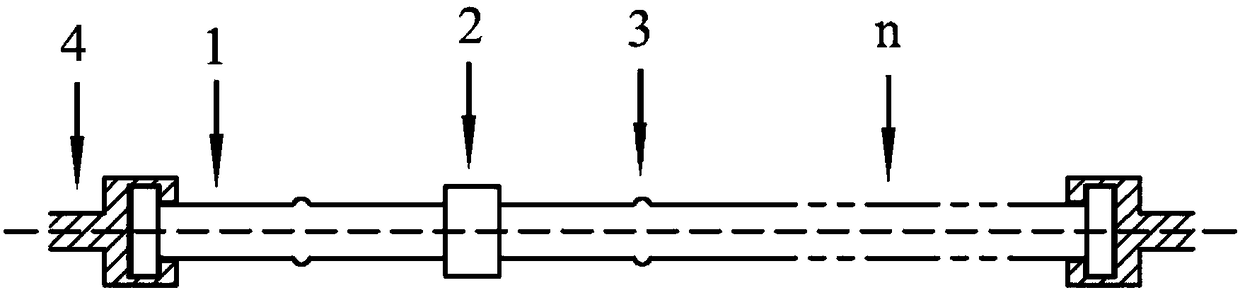

[0058] Its manufacturing method is identical with embodiment 1 manufacturing method, and difference is according to image 3 Shown is the manufacture of two or more product structures in series, and the design structure dimensions of each position are the same as those in Example 1 (where n≥2, indicating that the design includes two or more product structures). In order to ensure the uniformity of the pre-deformation treatment before use, the number of symmetrical structures of serial rivets can be designed according to the specific use conditions.

[0059] Same as the manufacturing method of Example 1, the image 3 The structural products are placed in a specific stretching device for uniform deformation, and then symmetrically cut along the middle of each product's protrusion point and the middle of the end to obtain a finished rivet, which can be riveted under specific working conditions, and can be...

Embodiment 3

[0062] The composition of Ti-based shape memory alloy rivets is Ti‐20Zr‐5Nb.

[0063] Its manufacturing method is the same as the preparation method of embodiment 2, according to the design concept of embodiment 2, such as Figure 4 Manufacture two and more as shown image 3 Structural parallel stretching product, the position design of each symmetrical node is the same as in Example 1, image 3 It is a schematic diagram of the product structure and manufacturing method of two or more rivets stretched in series (where n≥2, m≥2, indicating that the design includes two or more product structures). In order to ensure the uniformity of the pre-deformation treatment before use, the number of symmetrical structures of rivets in series and parallel connection Example 1 can be designed according to the specific use conditions.

[0064] Same as the method of use in Example 1, the Figure 4 The structural product is placed in a specific stretching device for uniform deformation, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com