Free-surface secondary reflection concentrator system for efficient solar energy thermal/electric conversion

A solar thermal and concentrating system technology, applied in the field of concentrating systems, can solve the problems of not being able to receive all the light spots, limited entrance area of the heat-absorbing cavity, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

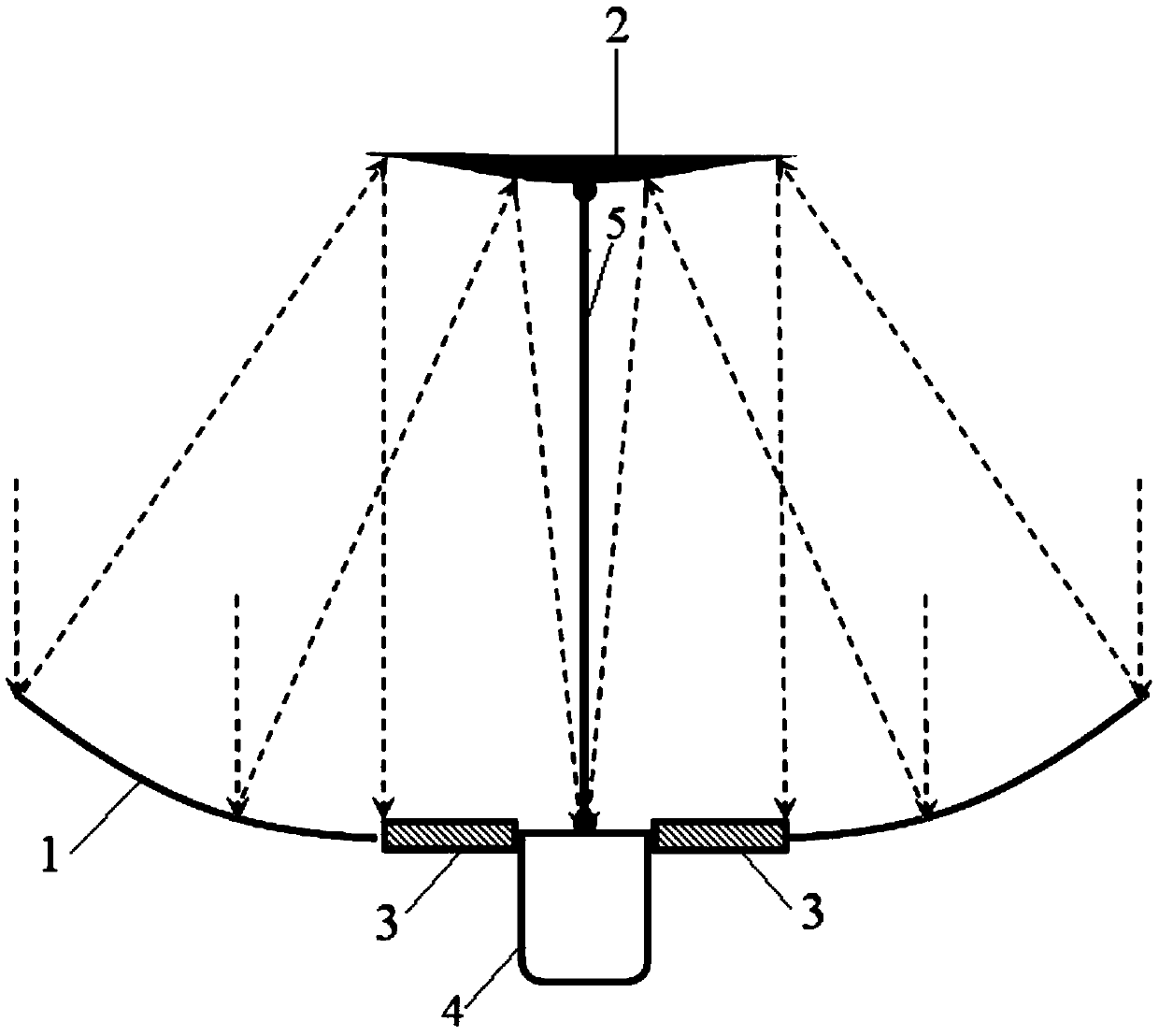

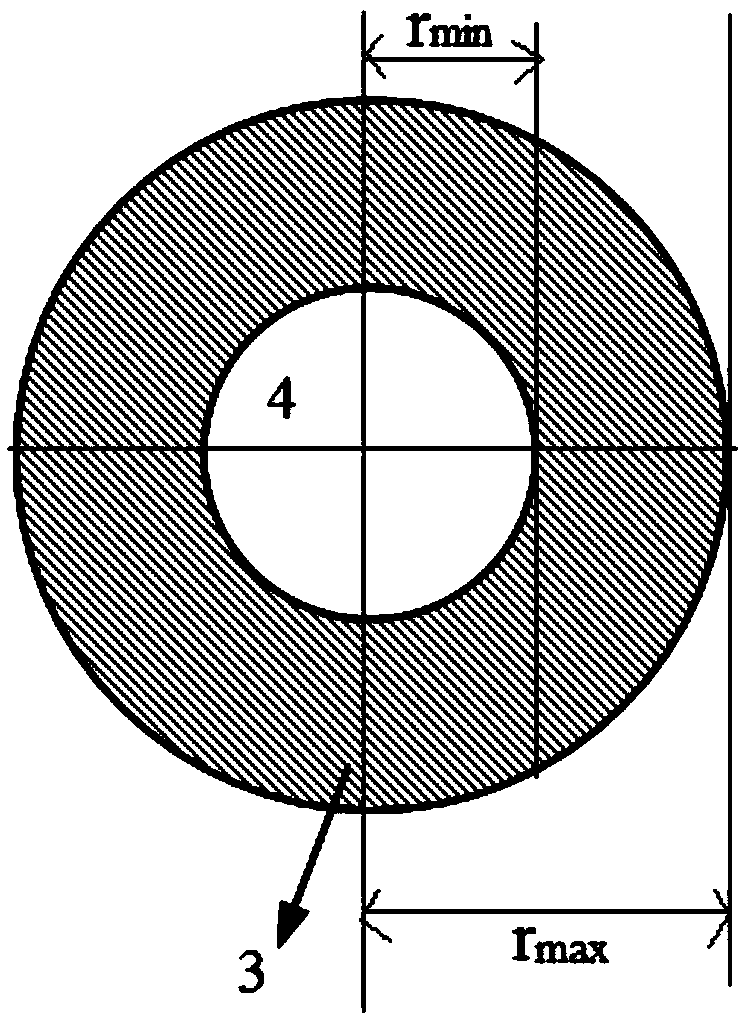

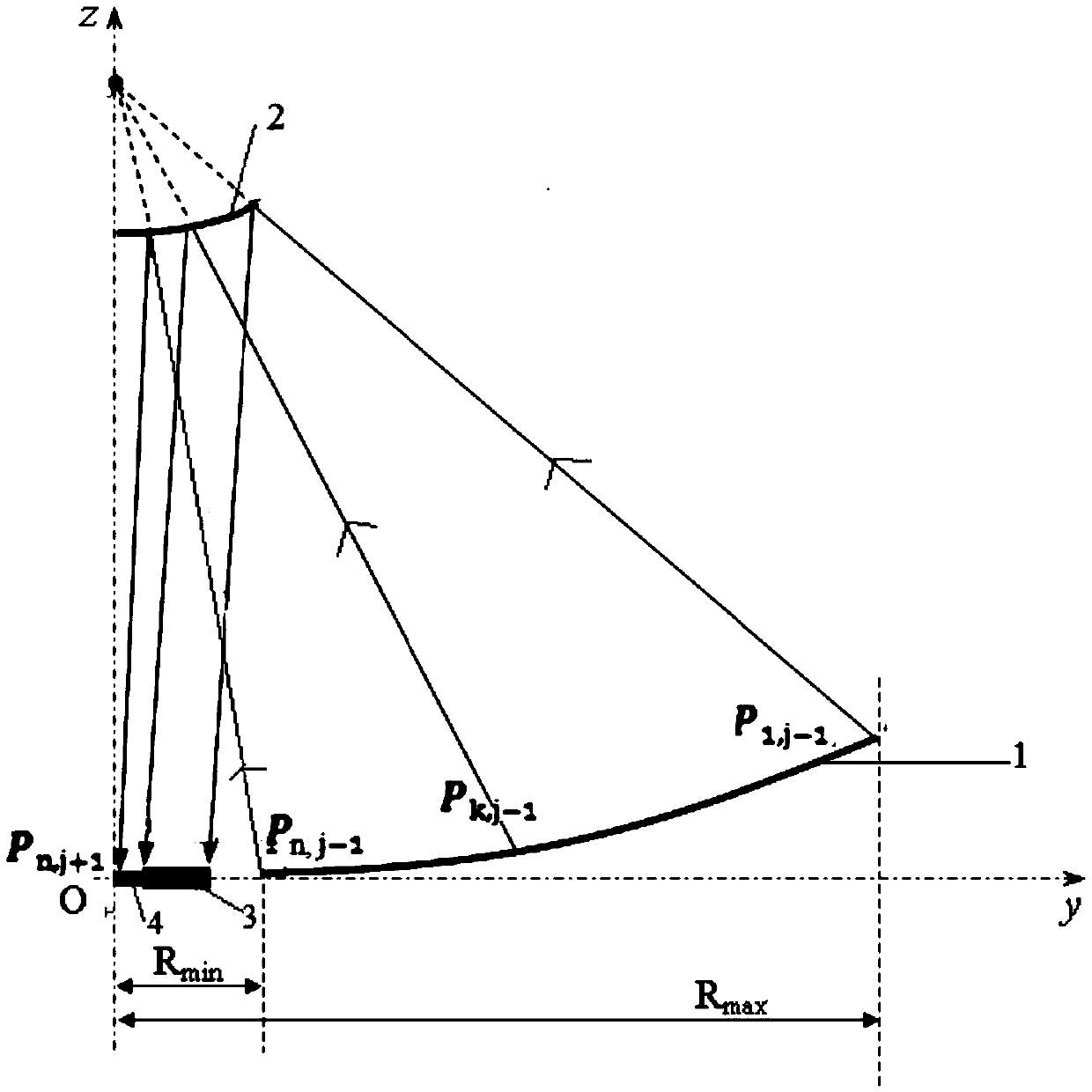

[0061] Specific Embodiment 1: This embodiment is a free-surface secondary reflection and concentrating system for solar thermal / electrical high-efficiency conversion, using a free-surface Cassegrain reflection and concentrating system, consisting of a primary mirror 1, a secondary mirror 2 and The receiver is composed of; the primary mirror 1, the secondary mirror 2 and the receiver are all axisymmetric structures, and the primary mirror 1, the secondary mirror 2 and the receiver are coaxial; the primary mirror 1 and the secondary mirror 2 are connected by a bracket 5 , the concave surface of the primary mirror 1 faces the secondary mirror 2, the receiver is fixed on the bracket 5, and the bracket 5 is arranged on the axis of the primary mirror 1, the secondary mirror 2 and the receiver; the receiver is composed of the heat absorber 4 and The concentrating photovoltaic cell panel 3 is composed of a flange, the flange is installed on the optical window end of the heat absorber 4...

specific Embodiment approach 2

[0100] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the receiver is installed at the intersection of the bracket 5 and the primary mirror 1 . Others are the same as the first embodiment.

specific Embodiment approach 3

[0101] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the receiver is installed on the bracket 5 and the distance from the primary mirror 1 is 1 / 4 of the length of the bracket 5 . Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com