Processing technology for needle plate

A processing technology and needle board technology, applied in the field of needle board processing technology, to achieve the effect of high success rate, high hardness, and small material deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

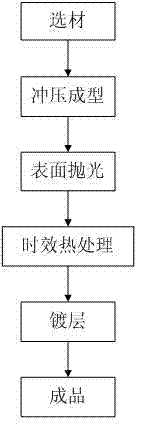

Method used

Image

Examples

Embodiment 1

[0029] (1), material selection: select a beryllium bronze thin strip with a beryllium (Be) content of 1.8% by weight as the base material;

[0030] (2) Stamping: stamping the base material;

[0031] (3), the surface is polished into semi-finished products;

[0032] (4) Aging heat treatment: the treatment temperature is 350 ℃, the treatment time is 2.5 hours, and the hardness reaches HV380;

[0033] (5) Coating: The surface is coated with a layer of chromium coating, and the surface hardness of the coating is HV800.

Embodiment 2

[0035] (1) Material selection: a titanium bronze thin strip with a titanium (Ti) content of 5% by weight is selected as the base material;

[0036] (2) Stamping: stamping the base material;

[0037] (3), the surface is polished into semi-finished products;

[0038] (4) Aging heat treatment: the treatment temperature is 450 ℃, the treatment time is 4 hours, and the hardness reaches HV400;

[0039] (5) Coating: The surface is coated with a nickel-based alloy coating, and the surface hardness of the coating is 1000.

Embodiment 3

[0041] (1), material selection: choose aluminum (Al) content of 8-12% by weight aluminum bronze thin strip plate as the base material;

[0042] (2) Stamping: stamping the base material;

[0043] (3), the surface is polished into semi-finished products;

[0044] (4) Aging heat treatment: the treatment temperature is 410℃, the treatment time is 2.5 hours, and the hardness reaches HV420;

[0045] (5) Coating: The surface is coated with a nickel-based alloy coating, and the surface hardness of the coating is HV850.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com