Elevator control cabinet

An elevator control and control cabinet technology, applied in the field of control cabinets, can solve the problems of large physical distance, heavy weight, large elevator control cabinet, etc., and achieve the effects of reducing manufacturing and processing costs, reducing space, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

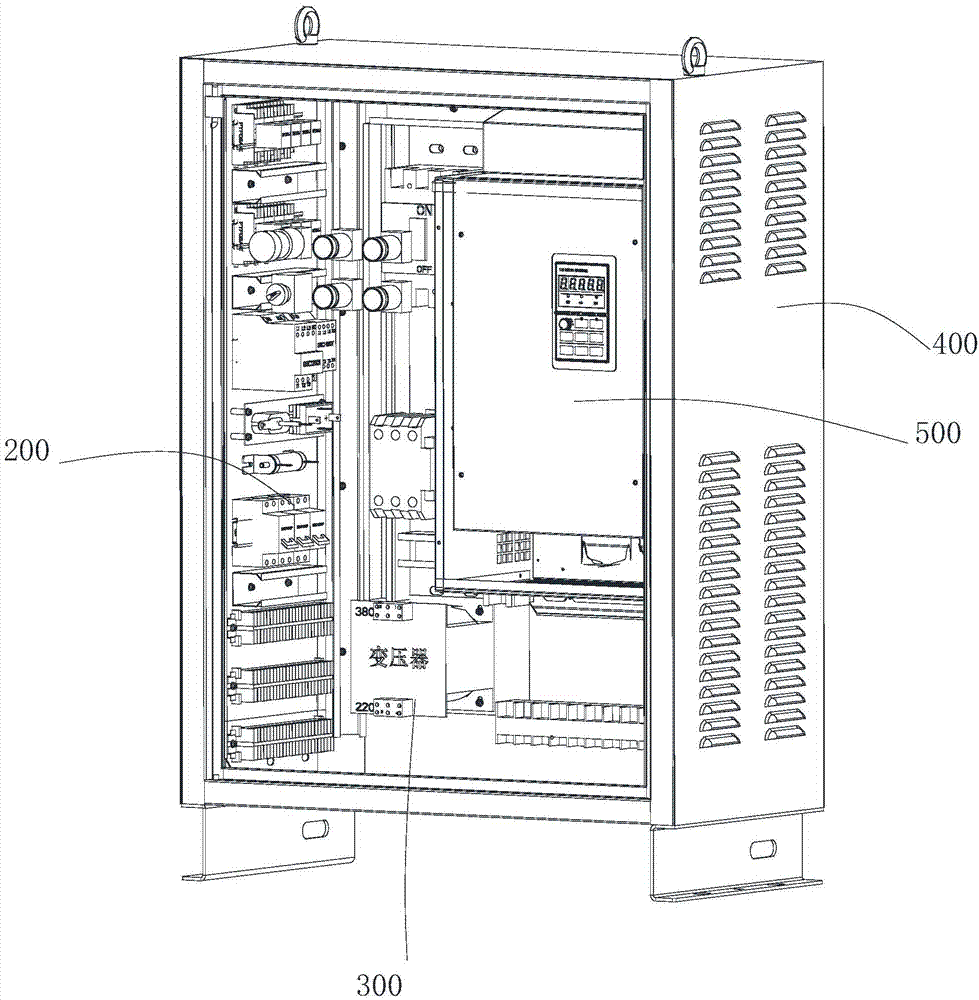

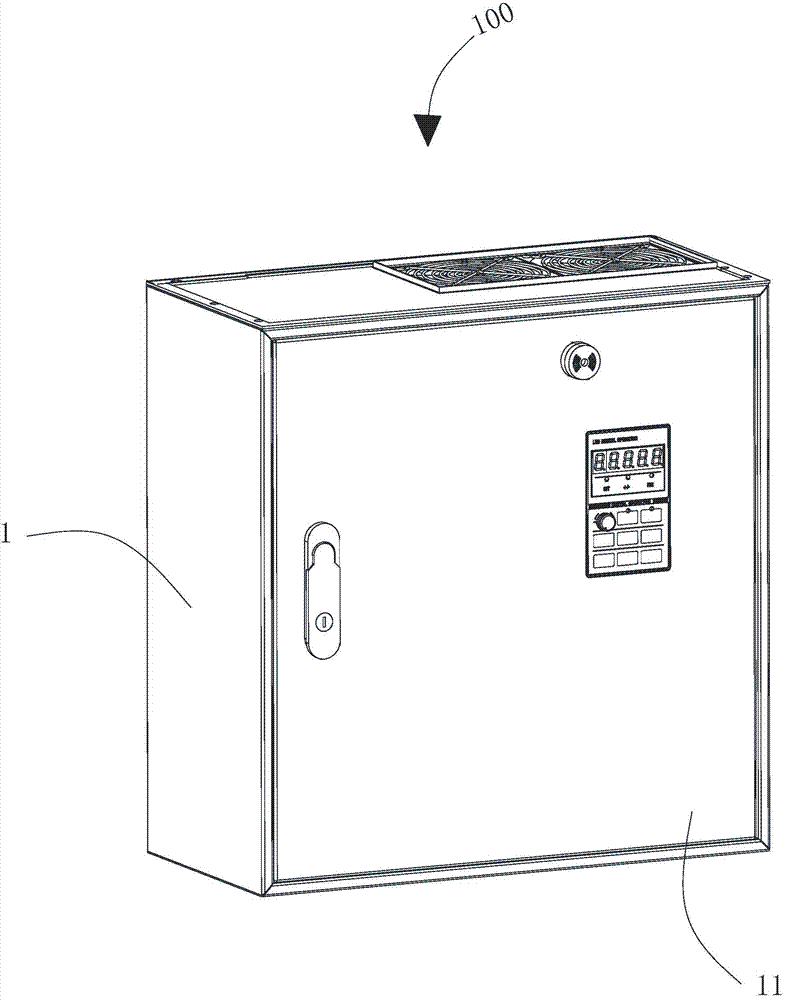

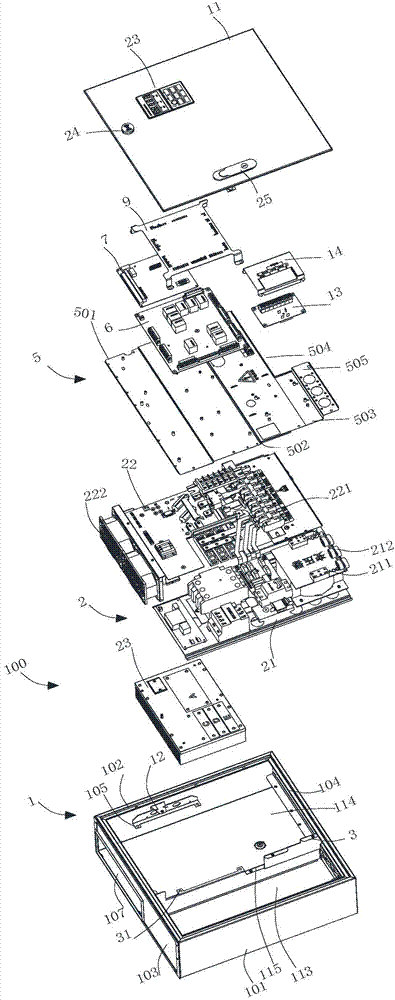

[0024] The invention provides a compact elevator control cabinet. In the elevator control cabinet, by changing the internal structure of the cabinet body and rearranging and assembling electrical components, the elevator control cabinet has a compact structure and a reduced volume, thereby reducing manufacturing and processing costs. At the same time, the housing of the original frequency converter is removed in the present invention, so that the space occupied by the frequency converter is greatly reduced, thereby further reducing the volume of the elevator control cabinet. In addition, in the present invention, the relays, rectifiers, resistors, and connectors used in the separate elevator control logic circuits in the prior art are integrated on a PCB board, and the electrical connections between the separate electrical components are passed through on the PCB board. This type of structure greatly reduces the space required for the elevator control logic circuit, thereby fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com