Manual pecan shell breaking device

A shell breaking device and technology for walnuts, which are applied in the fields of shelling, pod removal, food science, etc., can solve the problems of high shell breaking rate, unsatisfactory shell breaking effect, low breaking rate, etc., to reduce the breakage rate and uniform force , the effect of reducing sorting requirements

Inactive Publication Date: 2014-09-10

金华景腾科技有限公司

View PDF7 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

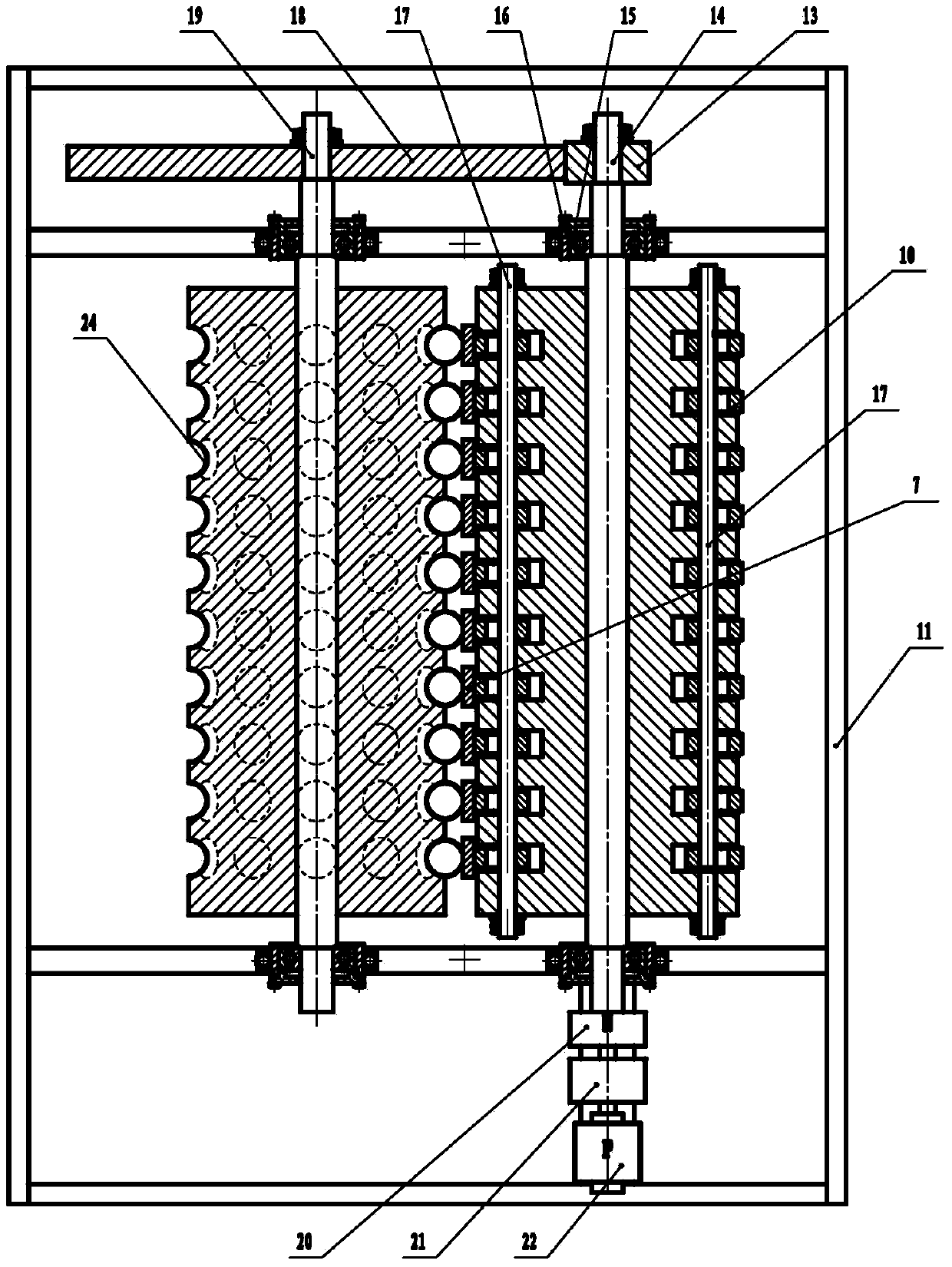

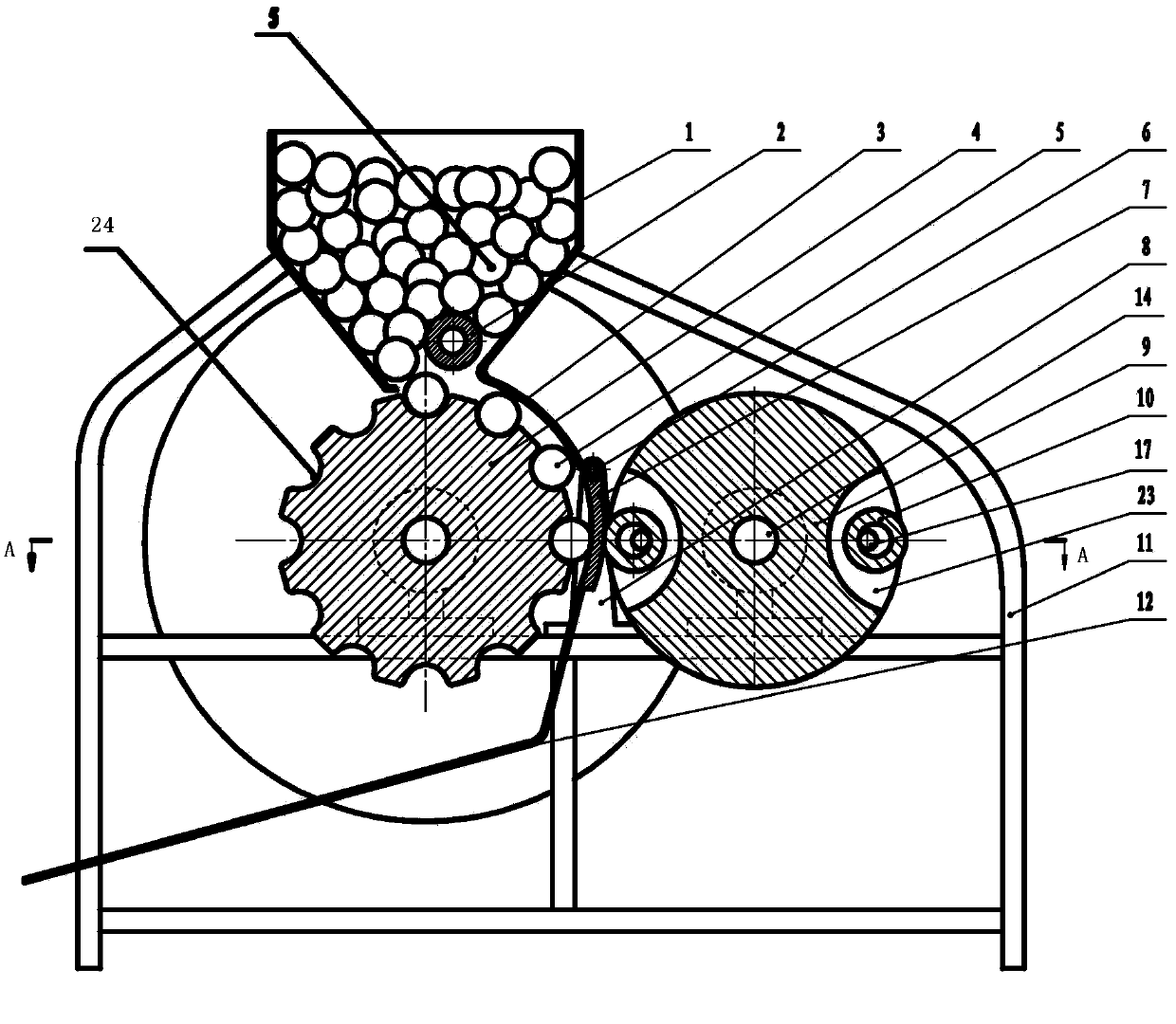

The invention discloses a manual pecan shell breaking device comprising a frame. The frame is provided with a feeding hopper, a transmission mechanism and a shell breaking mechanism. The transmission mechanism comprises a first central shaft and a second central shaft which are mounted on the frame, the first central shaft is provided with a small gear, the second central shaft is provided with a large gear, and the small gear and the large gear are mounted in an engaged manner; a hitting drum is fixedly connected to the first central shaft, and a material carrying drum is fixedly connected to the second central shaft; the circumference of the hitting drum is provided with evenly-distributed radial arc hitting wheel grooves along the axis, the hitting drum is provided with hitting wheel shafts sleeved with hitting wheels, and the hitting wheels are located in the arc hitting wheel grooves. Evenly-distributed spherical pits are formed in the circumference of the material carrying roller axially. The device has the advantages that structure is simple, usage is facilitated, requirements of pecan sorting are lowered, processing efficiency is improved greatly, and processing cost is reduced.

Description

technical field The invention relates to a device for manually peeling hickory nut shells, which is mainly used for cracking hickory nut shells and belongs to the field of food processing machinery and equipment. Background technique With the improvement of people's living standards, more and more people realize the nutritional value and health care function of pecans, and the market demand for pecans is also increasing. Yet the husk of hickory nut is hard, and there are multiple partitions in it, and walnut meat is embedded in the hard husk, often needs to use some special-purpose or auxiliary tools when eating, which brings trouble and inconvenience to eating. Hickory nuts are delicious and difficult to peel, which is a major technical problem that plagues the nut processing industry. The traditional processing method of peeling pecans by hand is: put the pecans in a special mold and beat them manually with a hammer. The traditional processing method is mainly done manual...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A23N5/00

Inventor 虞凤英

Owner 金华景腾科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com