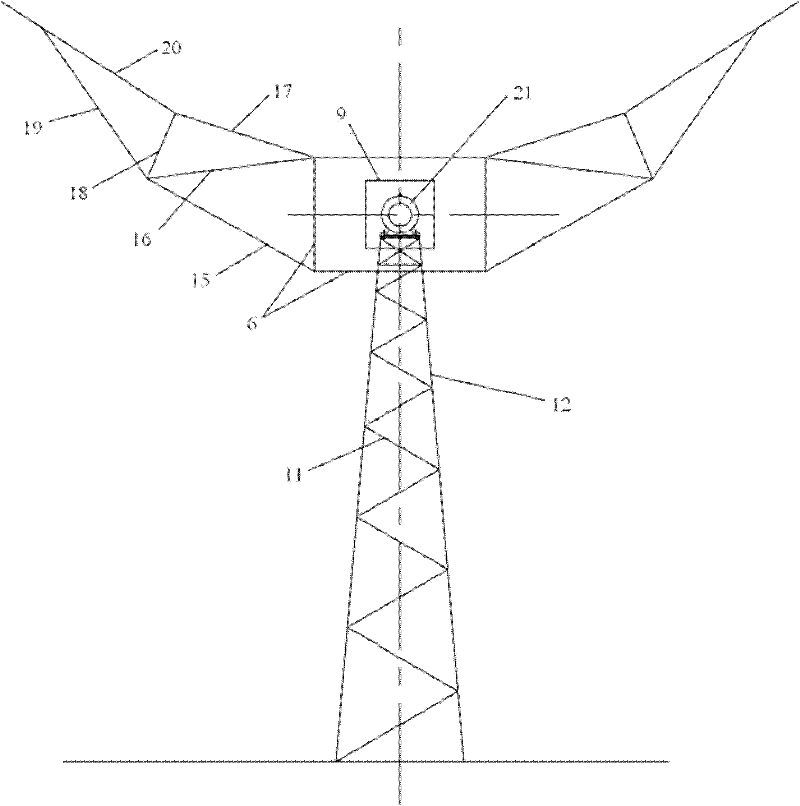

Spatial truss-type trough-type solar thermal power collector element support

A space truss, truss-type technology, applied in the field of space truss-type trough-type solar thermal power collector element brackets, can solve the problem of lack of its manufacturing process design scheme and method standards, affecting the optical efficiency of the trough-type reflective mirror surface, and lack of uniformity. Standard and other issues, to achieve the effect of small deformation, simple structure and convenient packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

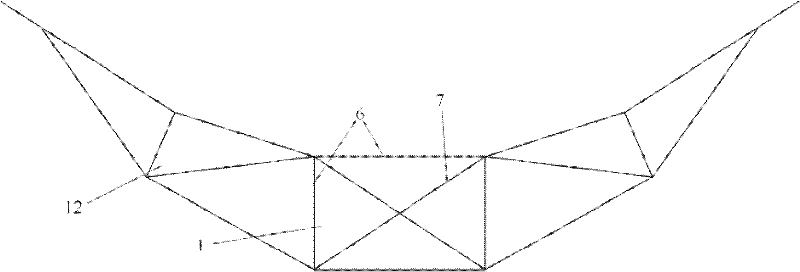

[0027] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

[0028] In this embodiment, each beam 5, column 12, reinforcement ribs, etc. are all made of Q235-B steel. The steel needs to undergo supplementary inspection, and the carbon content is not more than 0.22% or the welding test is required to ensure that the weldability is qualified. In this embodiment, the fixing bolts are all common grade C bolts.

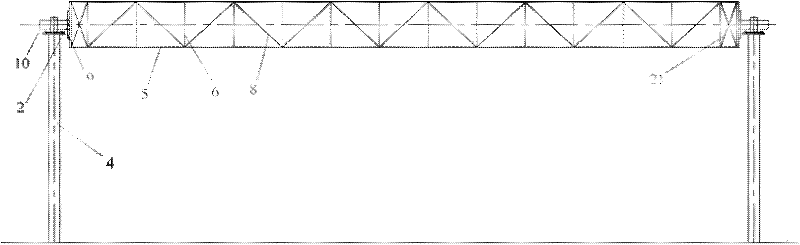

[0029] The beams 5 are 4 square steel tubes with a length of 9000 to 14000 mm, and the 4 beams 5 are fixed together by 16 fixed structures. In each fixed structure, two 700 mm long square steel tubes are connected vertically to the two adjacent beams 5 and 2 A 1000mm-long square steel pipe is transversely connected to two adjacent beams 5 to form a rectangular frame s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com