Molding mechanism for bending of suction tube

A technology for bending and forming a straw, which is applied to the field of straw bending and forming mechanisms, can solve the problems of high cost of straws, expensive manufacturing and forming equipment, etc., and achieves the effects of reducing manufacturing and processing costs and having a simple mechanism structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

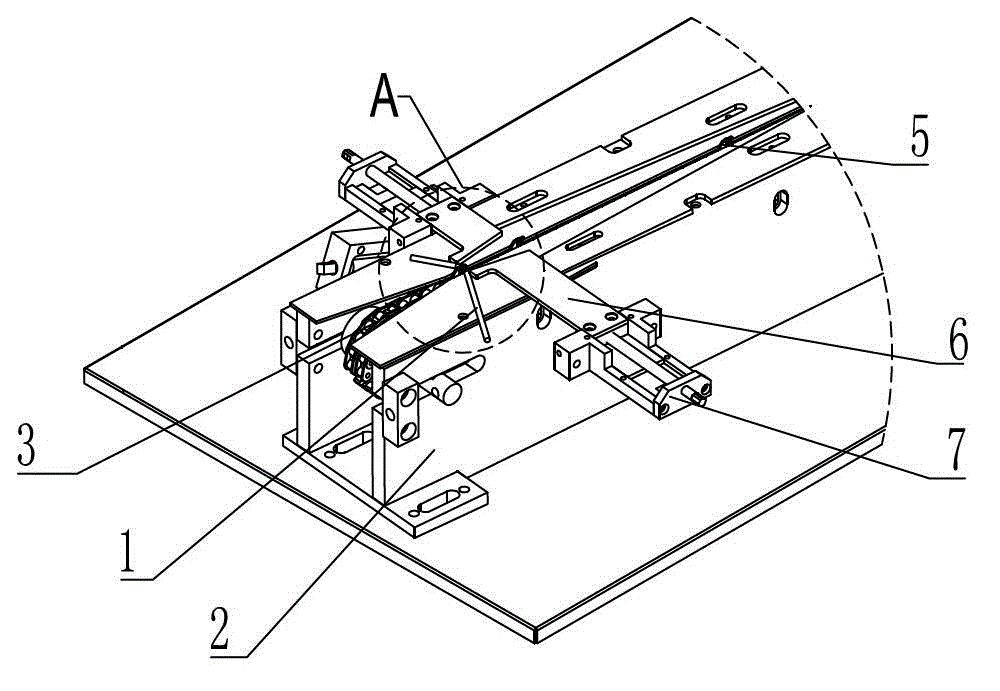

[0030] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

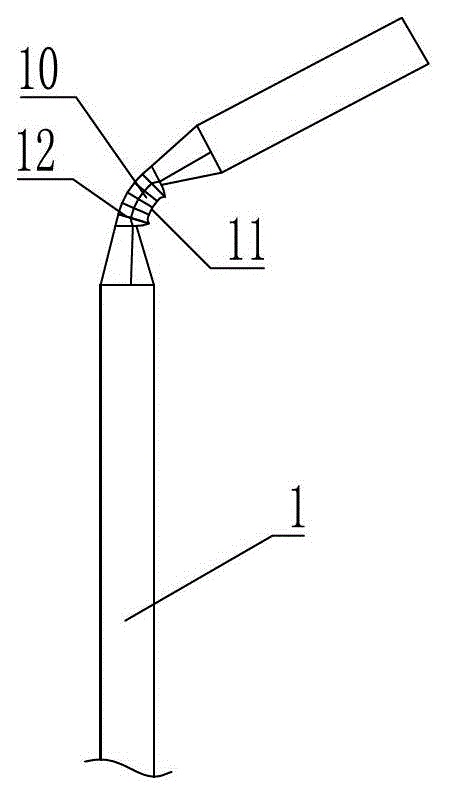

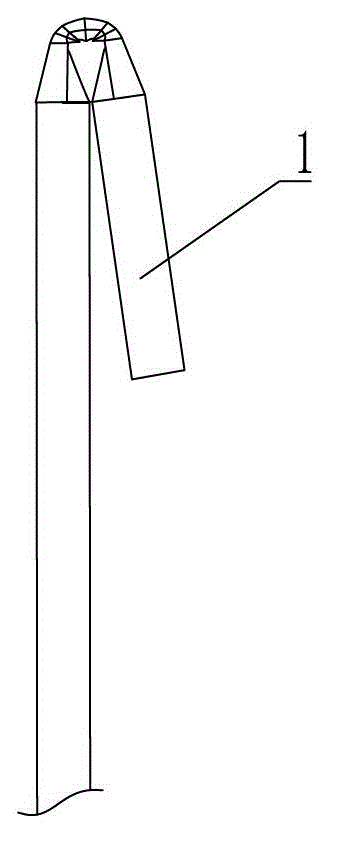

[0031] combine figure 1 , figure 2 As shown, the straw 1 manufactured by the straw bending and forming mechanism of this embodiment is made into a main rib 11 composed of a plurality of triangular prismatic bodies 10 by pressure at the inner corner of the bend, and the main rib is divided into several sections. There is a concave line 12 between each section. When the straw angle becomes smaller and folded inward, the raised prismatic body shrinks and narrows, and the concave line is inwardly folded and contracted between the prismatic bodies, thereby obtaining figure 2 closed straw.

[0032] When the straw is expanded at a larger angle, the raised prismatic shape expands outward, and the concave line moves outward in the radial direction of the tube, so that the closed straw opens and the internal space of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com