Flip LED (light-emitting diode) chip with high luminous efficiency and good heat radiating performance and preparation method thereof

A technology of LED chip and light extraction efficiency, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of chip pattern deviation, high production cost, and numerous production processes, and achieve the increase of ohmic contact area, saving production costs, saving The effect of the process step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

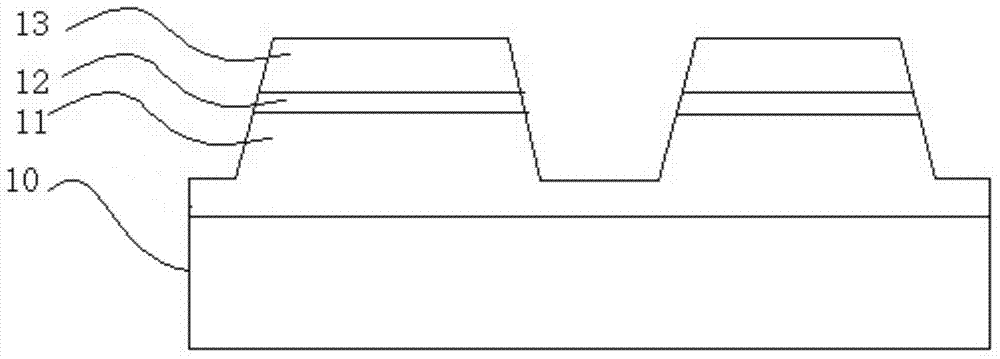

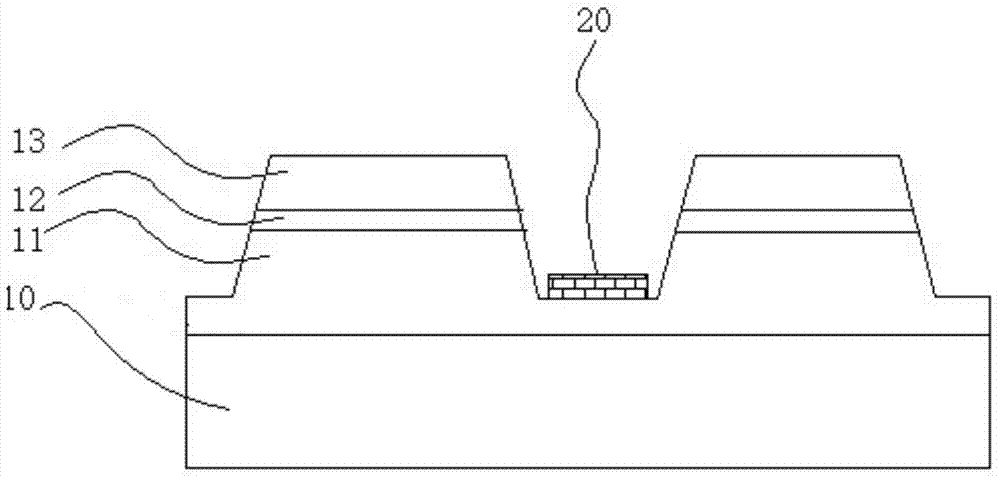

[0047] Embodiment 1 is an embodiment of a flip-chip LED chip.

[0048] The schematic cross-sectional view of the flip-chip LED chip provided in this embodiment is as follows: image 3 As shown, its top view schematic diagram is shown in Figure 4-a shown. The flip-chip LED chip includes an epitaxial substrate 100 , and an N-type epitaxial layer 101 , a light-emitting layer 102 and a P-type epitaxial layer 103 are sequentially stacked on the upper surface of the epitaxial substrate 100 . Wherein, a concave hole 500 is opened on the upper surface of the P-type epitaxial layer 103 , and the concave hole 500 penetrates downward through the light-emitting layer 102 and extends downward to the N-type epitaxial layer 101 . On the upper surface of the P-type epitaxial layer 103, a P contact metal layer 201, a P barrier protective layer 202, and a P surface electrode layer 203 are sequentially stacked, and the lower surface of the P barrier protective layer 202 overlaps with the uppe...

Embodiment 2

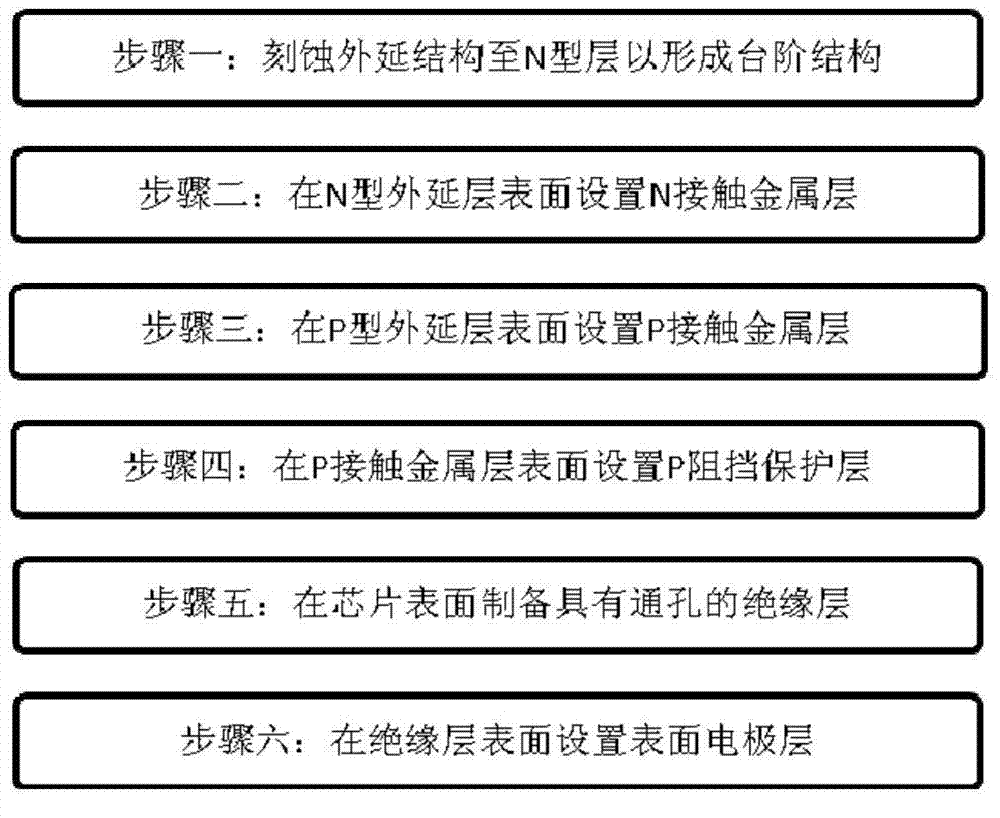

[0054] This embodiment is a preparation example of the flip-chip LED chip in embodiment 1, and the brief process of its preparation method can be found in Figure 5 .

[0055] In order to simplify the view, the schematic diagram of the steps involved in coating the photoresist layer and patterning the photoresist layer is not shown in this embodiment, which is common knowledge in the field, even if no explanation is given, those skilled in the art can understand .

[0056] Embodiment 2 is carried out according to the following steps, for ease of understanding, the following steps are combined Figure 6-9 and image 3 Make an introduction:

[0057] Step 1): Prepare an epitaxial wafer, which includes an epitaxial substrate 100, and an N-type epitaxial layer 101, a light-emitting layer 102, and a P-type epitaxial layer 103 sequentially laminated on the upper surface of the epitaxial substrate; The P-type epitaxial layer 103 upper surface prepares the P contact metal layer 201...

Embodiment 3

[0066] This embodiment is another preparation example of the flip-chip LED chip in embodiment 1, and the brief process of its preparation method can be found in Figure 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com