Rotor pump

A rotor pump and rotor technology, applied in the direction of pumps, rotary piston pumps, rotary piston machines, etc., can solve the problems of complex processing technology, increased displacement, unreliable sealing, etc., to achieve low noise, reduce loss, extend The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Realize the preferred embodiment of the present invention:

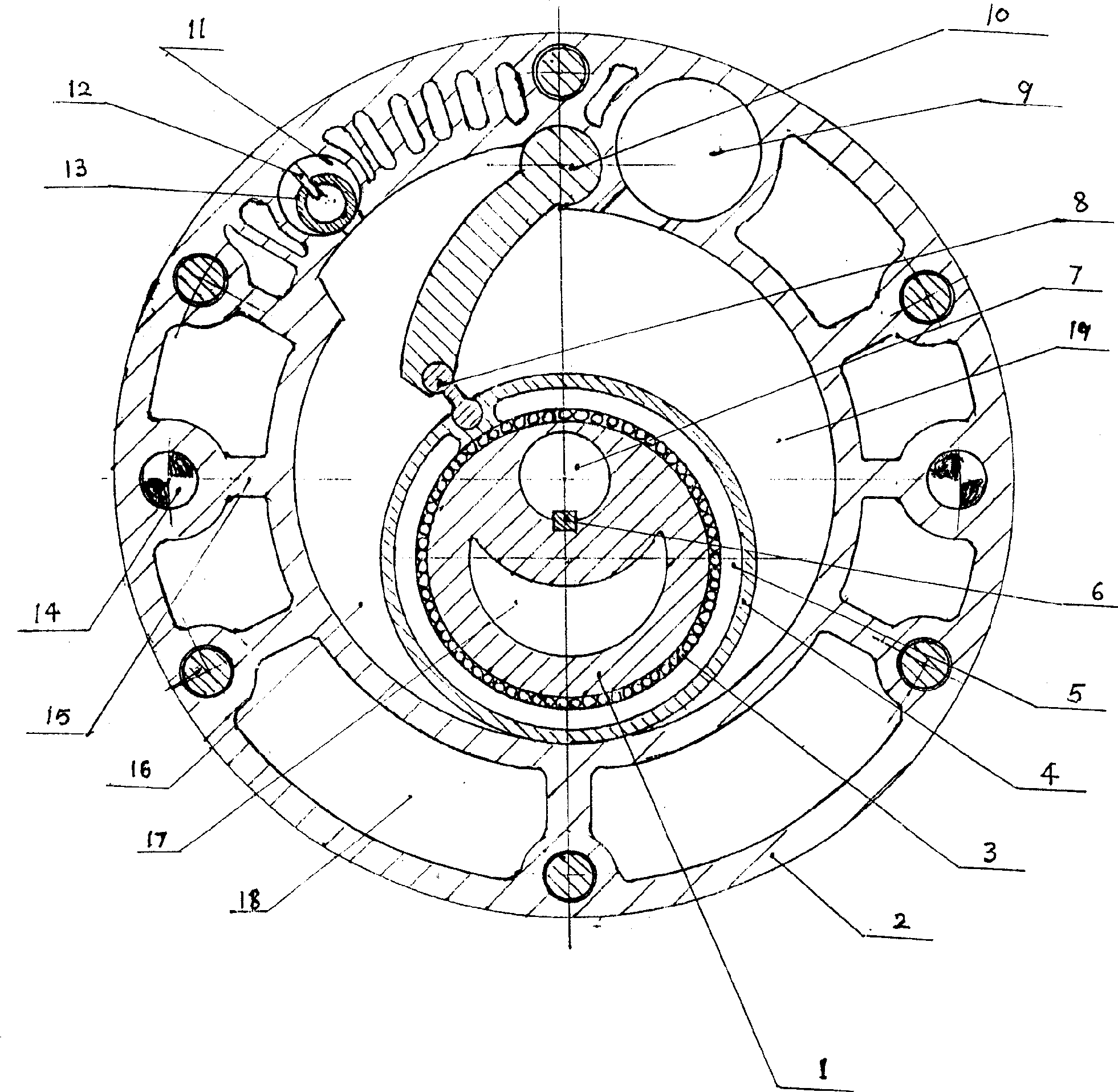

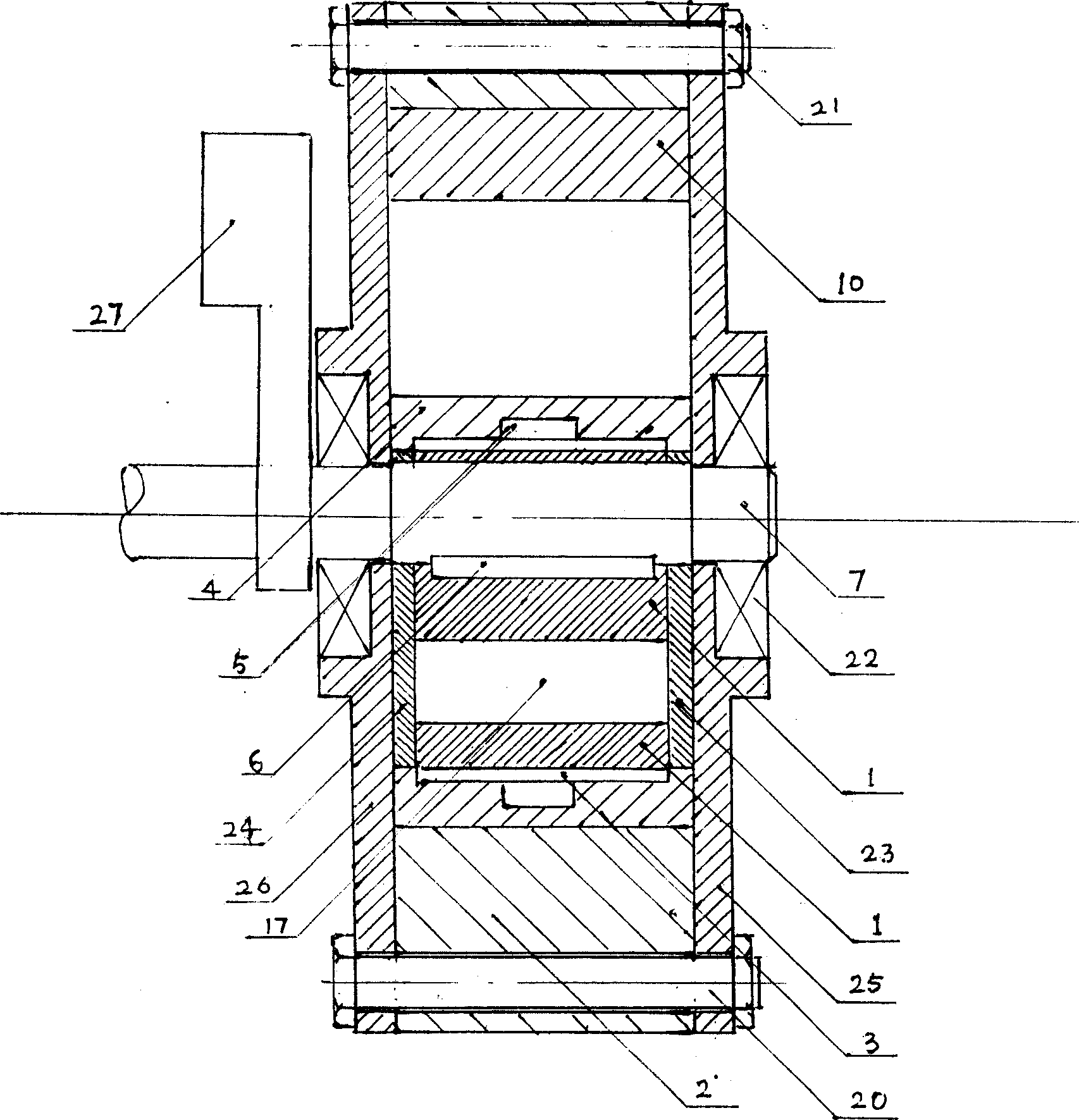

[0025] like figure 1 and figure 2 As shown, the rotor pump of the first embodiment of the present invention has a barrel-shaped cylinder stator 2, a moving ring 4, a rolling bearing 20 between the moving ring 4 and the rotor 1, and an eccentric rotor 1 that rotates around the axis. The rotor 1 is positioned in the circumferential direction on the shaft 7 by the key 6; the moving ring 4 on the rotor 1 is positioned as figure 1 In the way shown, the closed crescent-shaped cavity is divided into a high-pressure chamber 19 and a low-pressure chamber 16 through the interlocking movement of the stopper 10 and the joint 8, which is sucked by the suction port 9 of the low-pressure chamber, and then the sucked fluid is drawn from the discharge chamber through rotation. Exit 11 discharges.

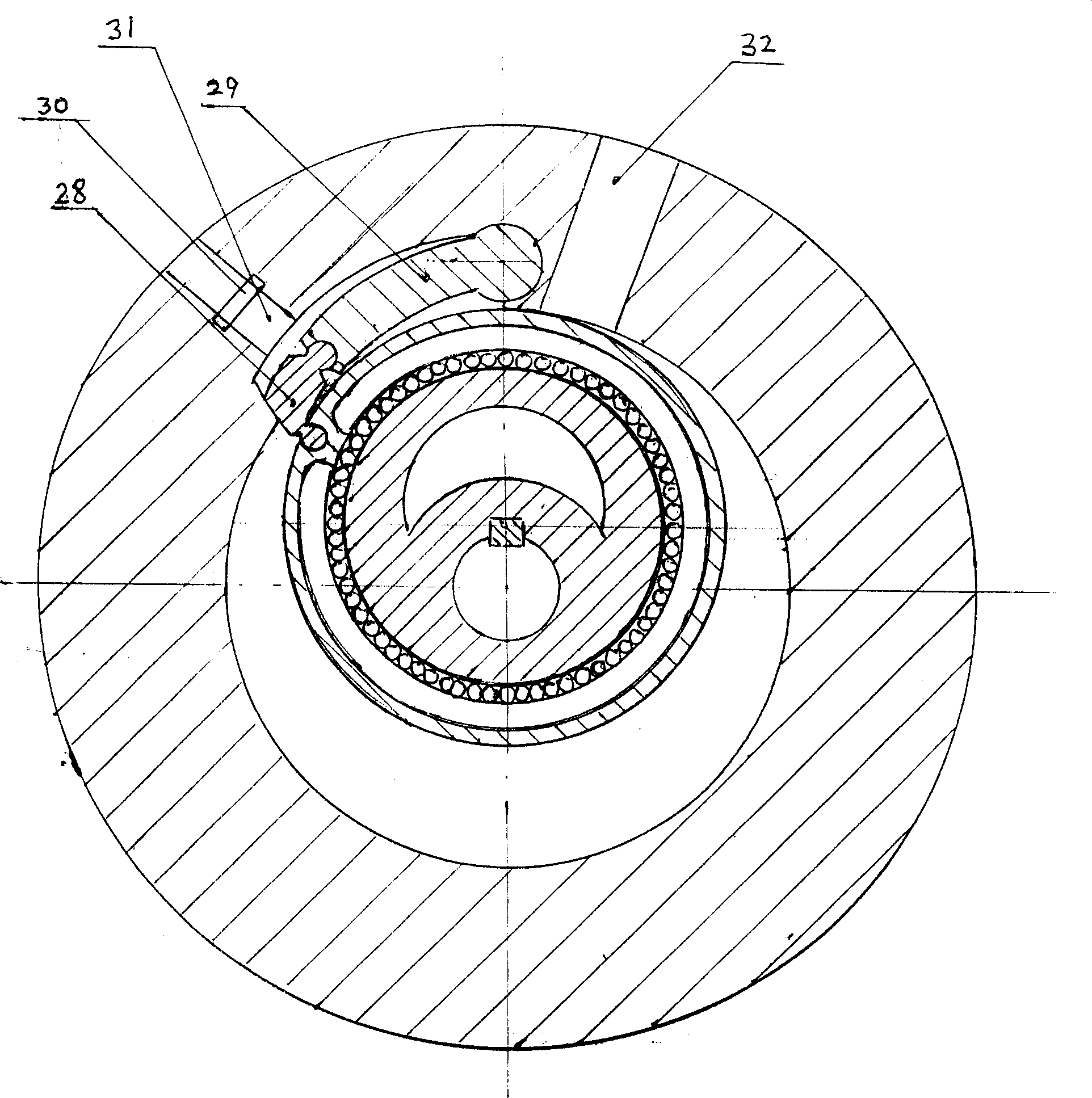

[0026] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com