Holder, rolling body and holder assembly and thrust bearing

A technology for cages and rolling elements, which is applied in the field of cages and thrust bearings, and can solve problems such as failure of thrust bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

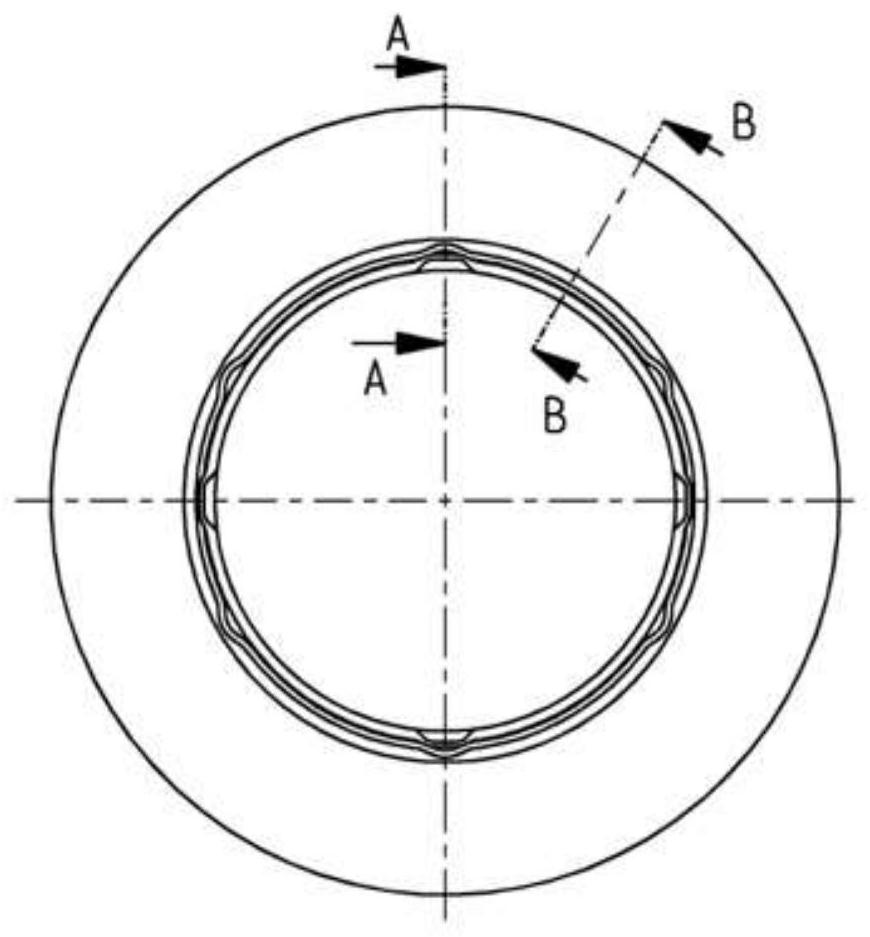

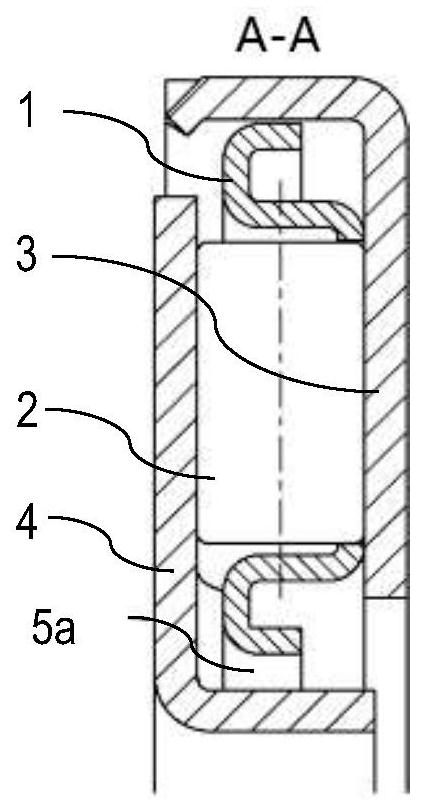

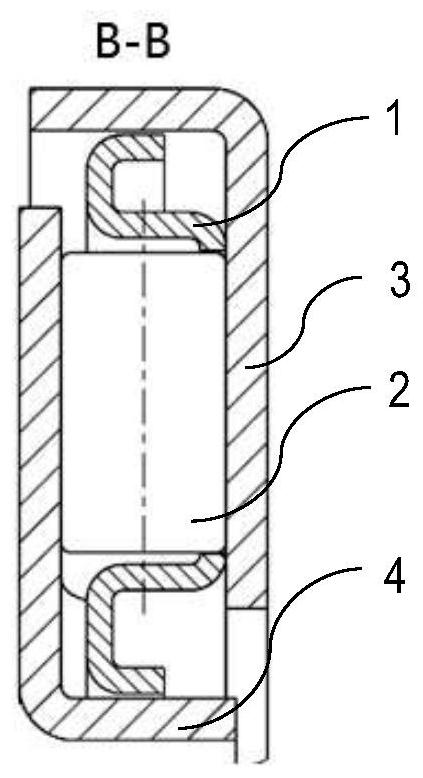

[0036] figure 1 shows a top view of a thrust bearing according to a preferred embodiment, figure 2 shows the basis figure 1 A half-sectional view of the thrust bearing at section A-A of , and image 3 shows the basis figure 1 A half-sectional view of the thrust bearing at section B-B.

[0037] The thrust bearing according to the present embodiment can be axially supported between the shaft and the bearing housing. Such as figure 2 with image 3 As shown, the thrust bearing includes a rolling element and cage assembly and two thrust washers 3,4. The rolling element and cage assembly includes a cage 1 and a plurality of rolling elements 2 .

[0038] Cage 1 is configured as a ring overall. The cage 1 here consists of a thin-walled annular plate part with a W-shaped cross section. The bulge in the radial middle area of the cage 1 forms pockets distributed in the circumferential direction, wherein the pockets penetrate the axial ends of the cage 1 in the axial directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com