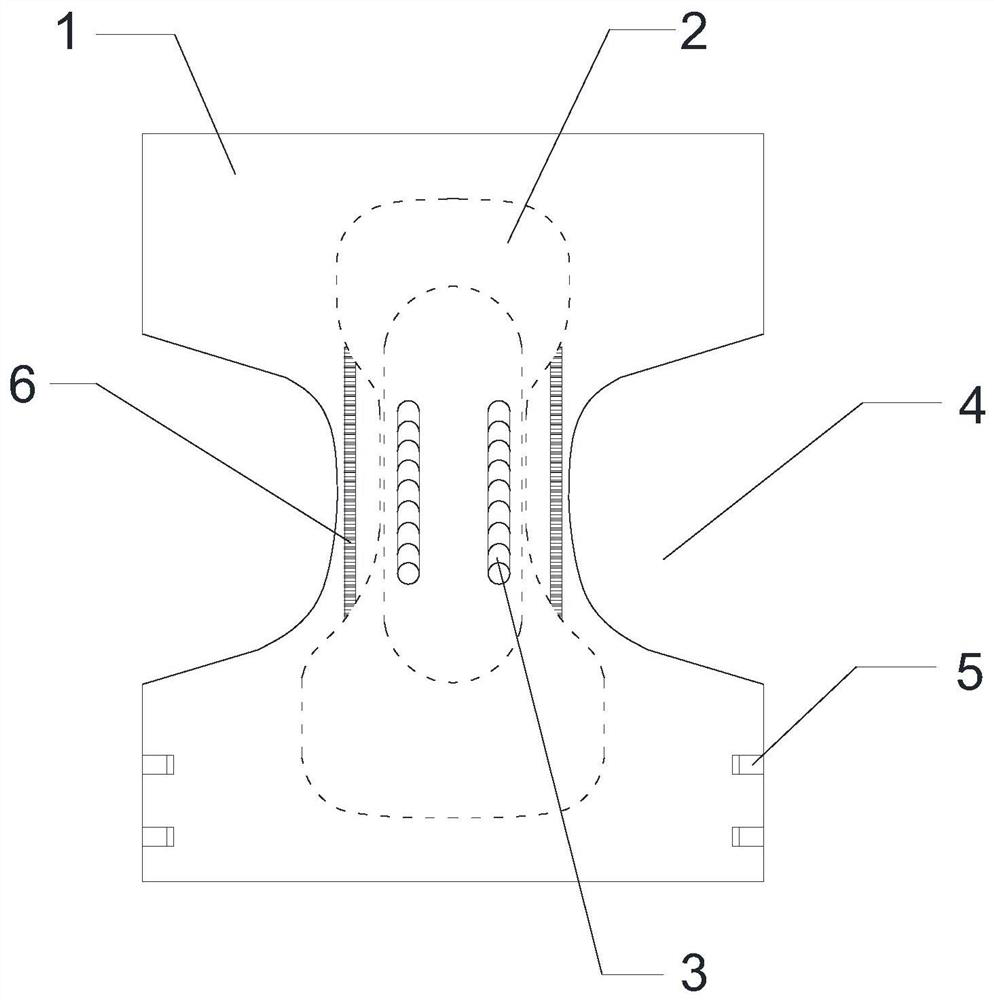

Paper diaper capable of keeping skin clean and healthy

A diaper and cleaning technology, which is applied in the field of sanitary products, can solve the problems of skin hazards, inability to absorb solid excrement, and reduce the contact area between solid excrement and skin, so as to keep clean and healthy, keep skin healthy, and increase the sense of space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

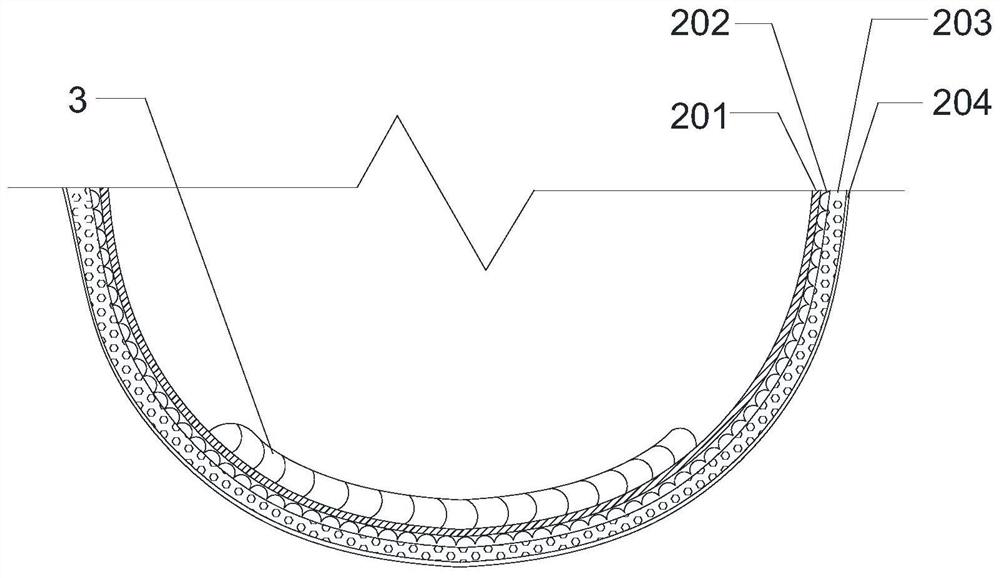

Method used

Image

Examples

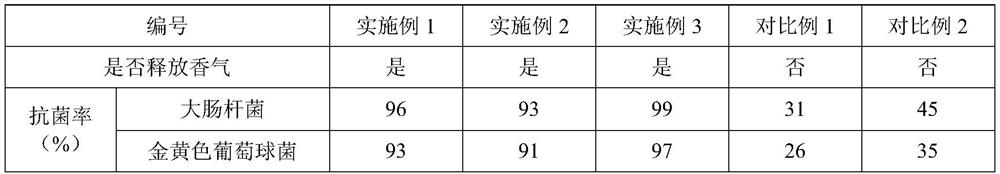

Embodiment 1

[0037] The absorbent core layer material of the absorbent part includes SAP, fluff pulp and antibacterial and deodorant microcapsules with a mass ratio of 15:25:1. The preparation method of antibacterial and deodorant microcapsules is:

[0038] (1) To 1.2mol / L FeSO under stirring state 4 Add 0.8mol / L NaHCO dropwise to the solution 3 solution, added NaHCO 3 with FeSO 4 The molar ratio is 2.1:1. After the precipitation is complete, filter, wash the product with deionized water, dry it in vacuum at 90°C, and grind it to obtain FeCO 3 powder;

[0039] (2) Add lavender essential oil and polymethyl methacrylate into dichloromethane, stir evenly to form an organic phase solution, wherein the mass ratio of lavender essential oil and polymethyl methacrylate is 1.2:1, polymethyl methacrylate in the organic phase solution The massfraction of methyl acrylate is 1.5%;

[0040] (3) FeCO 3 Add the powder into the organic phase solution, stir and disperse evenly to obtain an organic di...

Embodiment 2

[0043] The absorbent core layer material of the absorbent part includes SAP, fluff pulp and antibacterial and deodorant microcapsules with a mass ratio of 10:30:1. The preparation method of antibacterial and deodorant microcapsules is:

[0044] (1) To 1mol / L FeSO under stirring state 4 Add 0.5mol / L NaHCO dropwise to the solution 3 solution, added NaHCO 3 with FeSO 4 The molar ratio is 2:1, after the precipitation is complete, filter, wash the product with deionized water, dry it in vacuum at 80°C, and grind it to get FeCO 3 powder;

[0045] (2) Add peppermint essential oil and polymethyl methacrylate into dichloromethane, stir evenly to form an organic phase solution, wherein the mass ratio of lavender essential oil and polymethyl methacrylate is 1:1, polymethyl methacrylate in the organic phase solution The massfraction of methyl acrylate is 1%;

[0046] (3) FeCO 3 Add the powder into the organic phase solution, stir and disperse evenly to obtain an organic dispersed p...

Embodiment 3

[0049] The absorbent core layer material of the absorbent part includes SAP, fluff pulp and antibacterial and deodorant microcapsules with a mass ratio of 20:15:1. The preparation method of antibacterial and deodorant microcapsules is:

[0050] (1) To 1.5mol / L FeSO under stirring state 4 Add 1mol / L NaHCO dropwise to the solution 3 solution, added NaHCO 3 with FeSO 4 The molar ratio is 2.2:1. After the precipitation is complete, filter, wash the product with deionized water, dry it in vacuum at 100°C, and grind it to obtain FeCO 3 powder;

[0051] (2) Add peppermint essential oil and polymethyl methacrylate into dichloromethane, stir evenly to form an organic phase solution, wherein the mass ratio of lavender essential oil and polymethyl methacrylate is 1.5:1, polymethyl methacrylate in the organic phase solution The massfraction of methyl acrylate is 2%;

[0052] (3) FeCO 3 Add the powder into the organic phase solution, stir and disperse evenly to obtain an organic dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com