Multi-angle radiation fin group forming method and radiator

A technology of heat sink group and heat sink, which is applied to heat exchange equipment, modification by conduction heat transfer, cooling/ventilation/heating transformation, etc. It is not easy to circulate and other problems, and achieves the effect of compact structure, improved heat dissipation efficiency, and accelerated speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

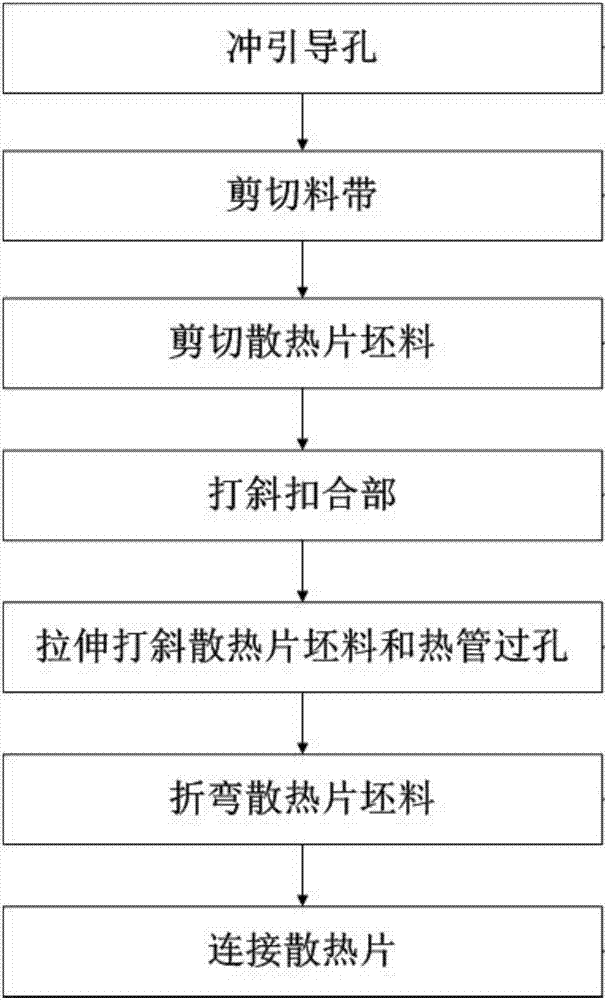

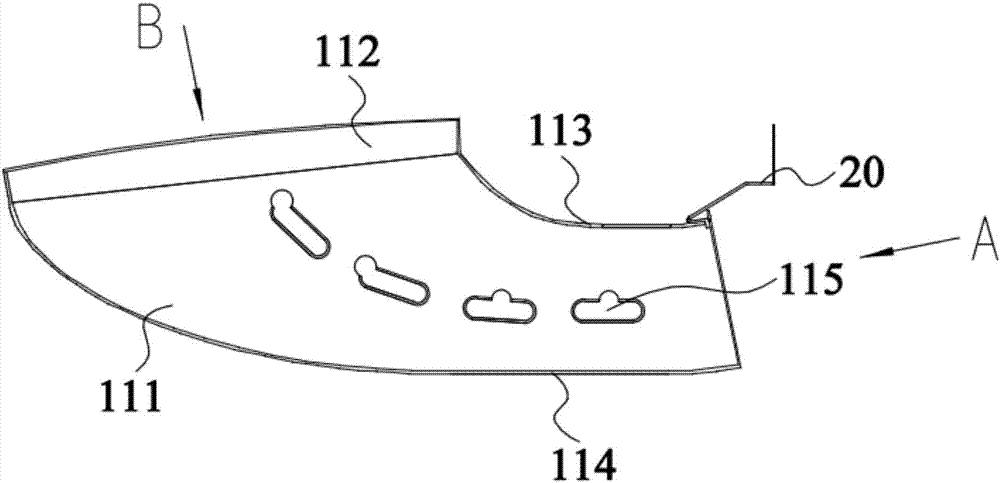

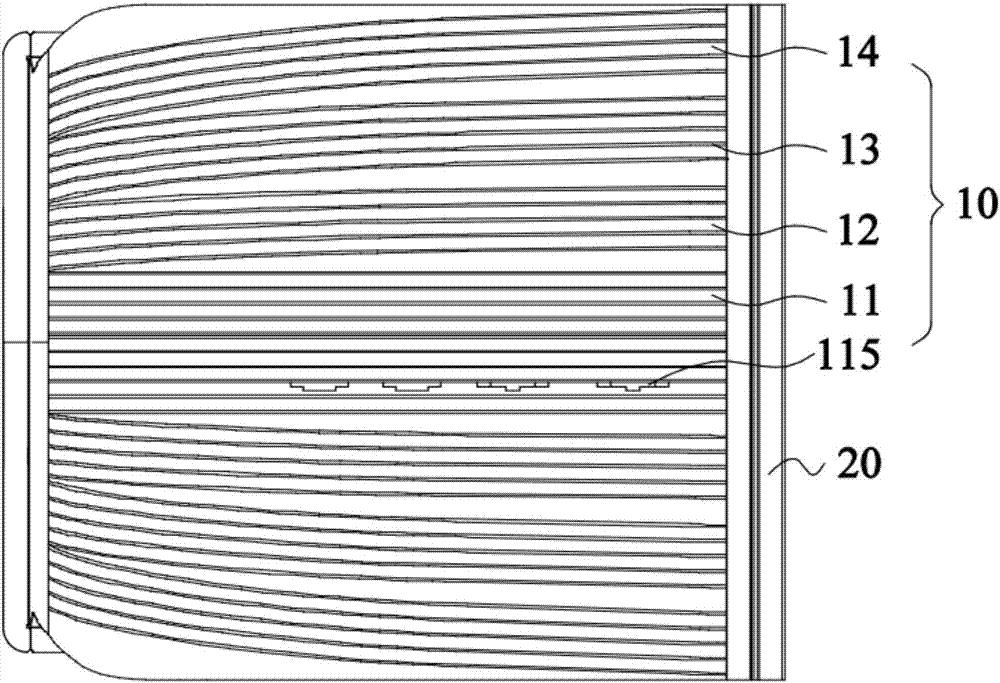

[0048] This embodiment discloses a method for forming a multi-angle heat sink. First, the heat sink blank at the oblique fastening part is drawn and obliquely obtained to obtain an arc-shaped heat sink blank, and then the heat sink blank is bent to obtain The heat sinks with snap-fit folds 113 are fastened together to obtain the multi-angle heat sink set 10 .

[0049] The multi-angle heat sink group produced by the multi-angle heat sink composition method of this embodiment can not only manufacture heat sinks with different stretching angles and shapes, but also increase the heat dissipation surface area of the multi-angle heat sink group; and the riveted The multi-angle heat sink group forms an included angle at the air inlet and air outlet. The space occupied by each heat sink is not repeated,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com