Horizontal pushing and clamping type two-cylinder double-side braking retarder actuator

An actuating device and dual-cylinder technology, which is applied in rail brakes, transportation and packaging, railway car body components, etc., can solve the problem of not being able to realize single-track control cars and double-track control cars at the same time, complicated clamping manufacturing process, and unfavorable use of hydraulic systems, etc. problem, to achieve the effect of low pressure, easy lubrication and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

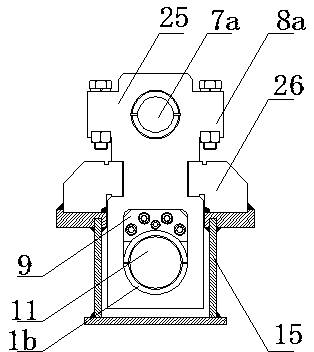

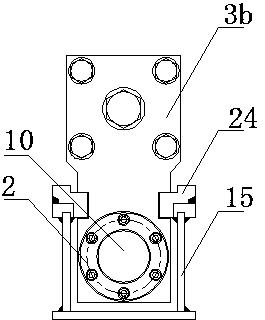

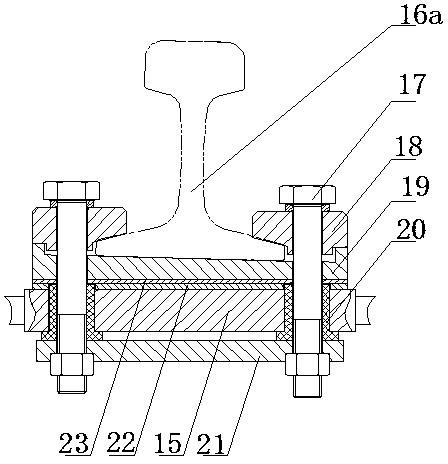

[0030] This embodiment provides a figure 1 The shown double-cylinder flat-push pincer type double-sided brake reducer actuator includes a joist 15, a left basic rail 16a and a right basic rail 16b that are arranged on the top surfaces of the left and right ends of the joist 15 and are parallel to each other, The double-acting oil cylinder that is arranged between the left basic rail 16a and the right basic rail 16b and is connected to the top surface of the joist 15 through the cylinder support slider 28 is arranged on the outside of the left basic rail 16a and the right basic rail 16b and passes through the outer support seat The left outer support seat 4a and the right outer support seat 4b that the slider 29 is connected with the top surface of the joist 15 are arranged on the outside of the left basic rail 16a and the right basic rail 16b and pass through the top of the inner support seat slider and the joist 15. The left inner support seat 6a and the right inner support s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com