Synchronizer-free shifting system for regulating speed of intermediate shaft of electric automobile

An intermediate shaft and speed regulation technology, which is applied in the automatic mechanical transmission (hereinafter referred to as AMT) shift system and the synchronizerless shift system field, can solve the problems of increased quality, volume and cost, increased volume and quality, and labor costs. It can reduce the adaptability and other problems, and achieve the effect of simple structure, reduced output torque requirements, reduced load and power requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

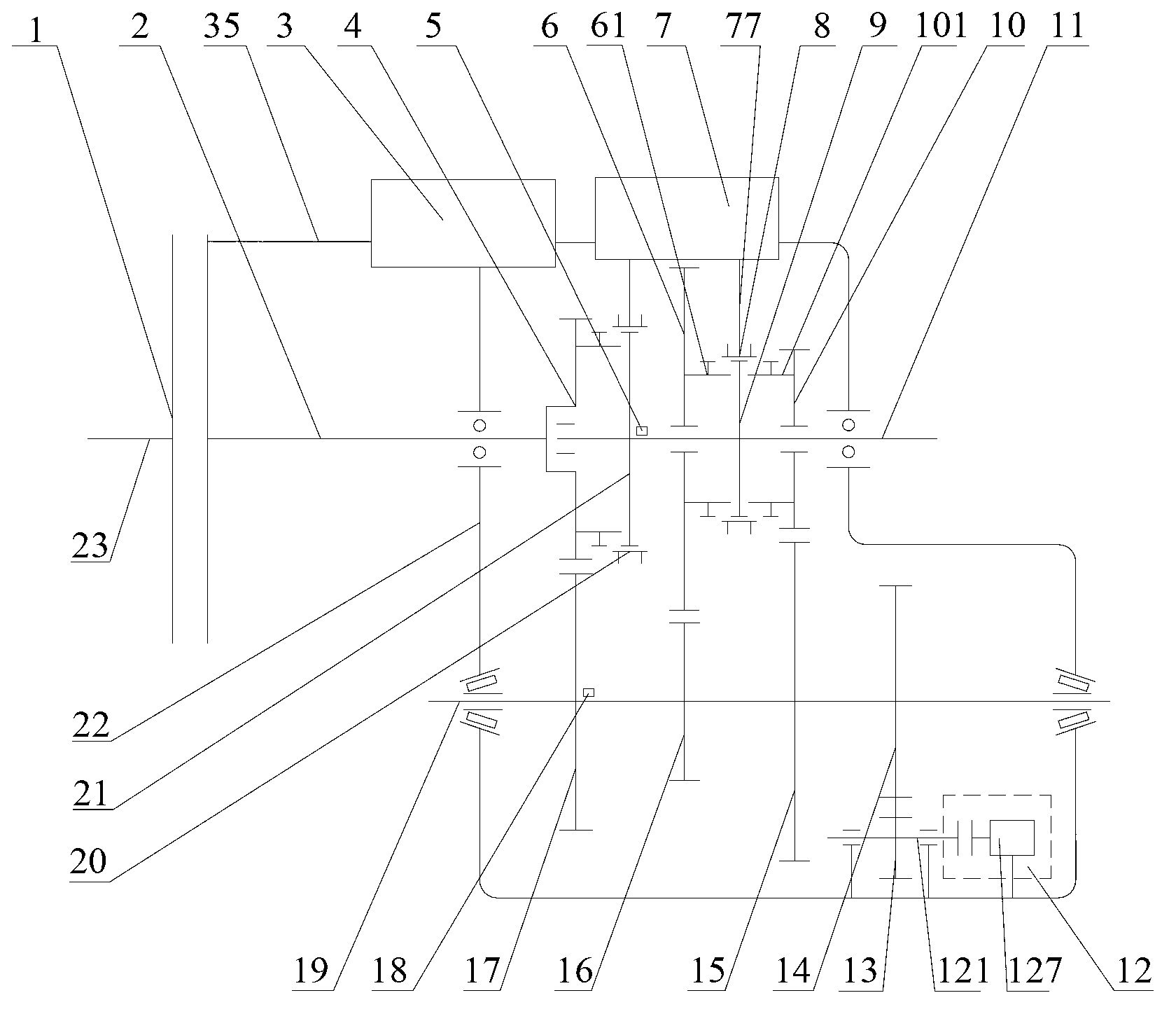

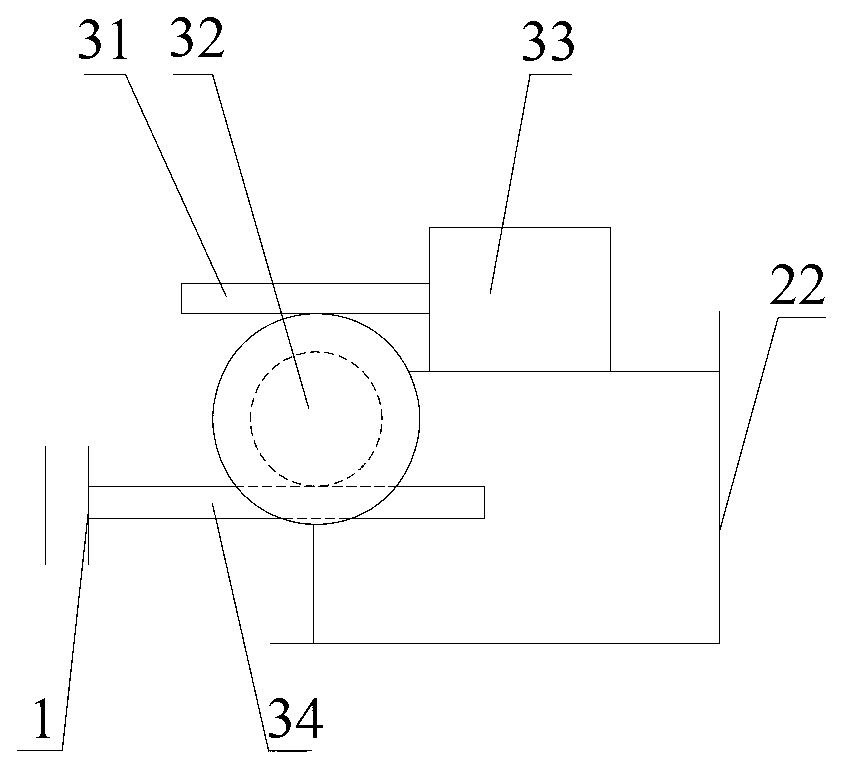

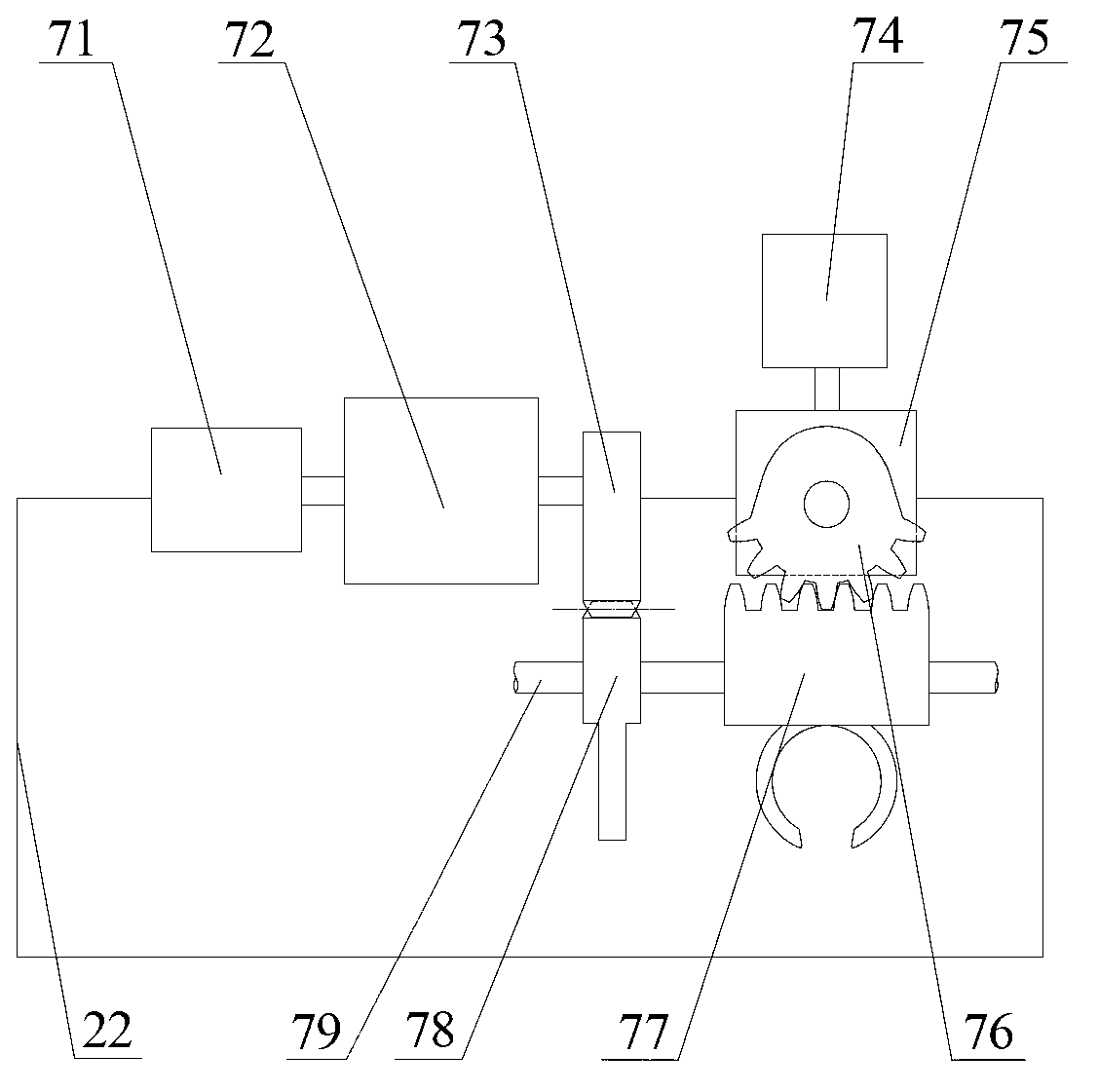

[0029] The non-synchronizer shifting system for electric vehicles to adjust the speed of the intermediate shaft proposed by the present invention has a structure such as figure 1 Shown, driving motor output shaft 23, clutch 1, input shaft 2, intermediate shaft 19, output shaft 11, clutch operating mechanism 3, gear shift actuator 7, transmission mechanism and speed regulating connection mechanism 12. The drive motor output shaft 23 is separated and engaged with the input shaft 2 through the clutch 1 .

[0030] In the above-mentioned non-synchronized gear shifting system, the input shaft 2 is supported on the gearbox body 22 through a ball bearing, the front end of the input shaft 2 is connected with the clutch 1, and the rear end of the input shaft 2 is the second-speed driving gear 4 of the input shaft ;

[0031] Described transmission mechanism is supported on the gearbox body 22, and transmission mechanism is made up of driving gear 13 and driven gear 14, and driving gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com