Low-power-consumption and large-flow high-speed switching valve

A high-speed switching valve and high-flow technology, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of limiting the application range of hydraulic high-speed punching machines and cannot be applied, and achieve low cost, easy processing, and valves. The effect of small flow pressure loss at the port

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

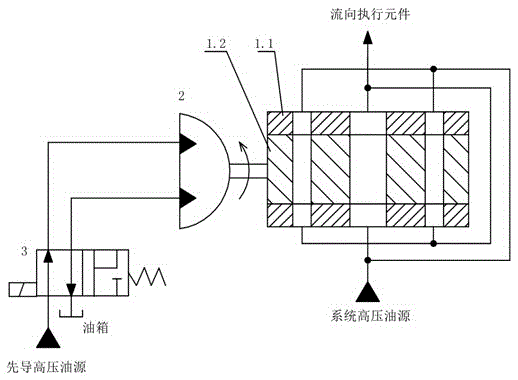

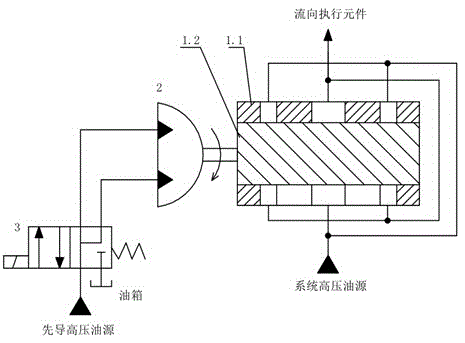

[0016] Such as figure 1 As shown, the present invention is made up of valve sleeve 1.1, spool 1.2, differential swing cylinder 2 and high-speed switching valve 3. The spool 1.2 is installed in the valve sleeve 1.1, forming a rotary valve type main valve structure. The spool 1.2 has three straight flow passages in the radial direction, and the three flow passages are distributed in sequence along the axial direction, and the centerlines of two adjacent flow passages have an equal distance in the axial direction; the two end flow passages The flow areas are equal, and the sum of the two flow areas is equal to the flow area of the middle channel. The valve sleeve 1.1 has a straight-through flow channel at the position corresponding to the flow channel of the valve core 1.2, which has the same shape as the flow channel of the valve core 1.2. The direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com