Pressure expander of centrifugal compressor

A centrifugal compressor and diffuser technology, which is applied in the direction of machine/engine, mechanical equipment, engine manufacturing, etc., can solve the problems of large airflow angle of attack and enlarge the working range, so as to increase the flow rate, improve the incident airflow angle, prevent The effect of surge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

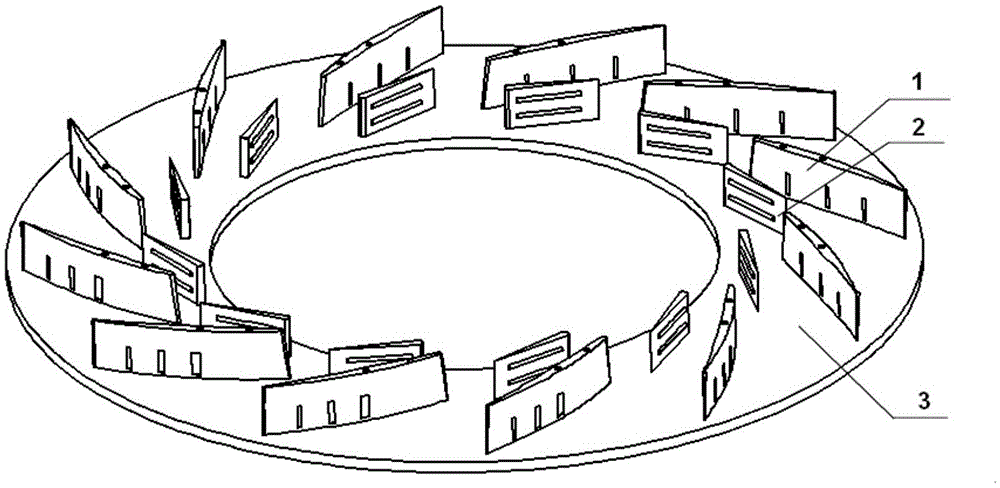

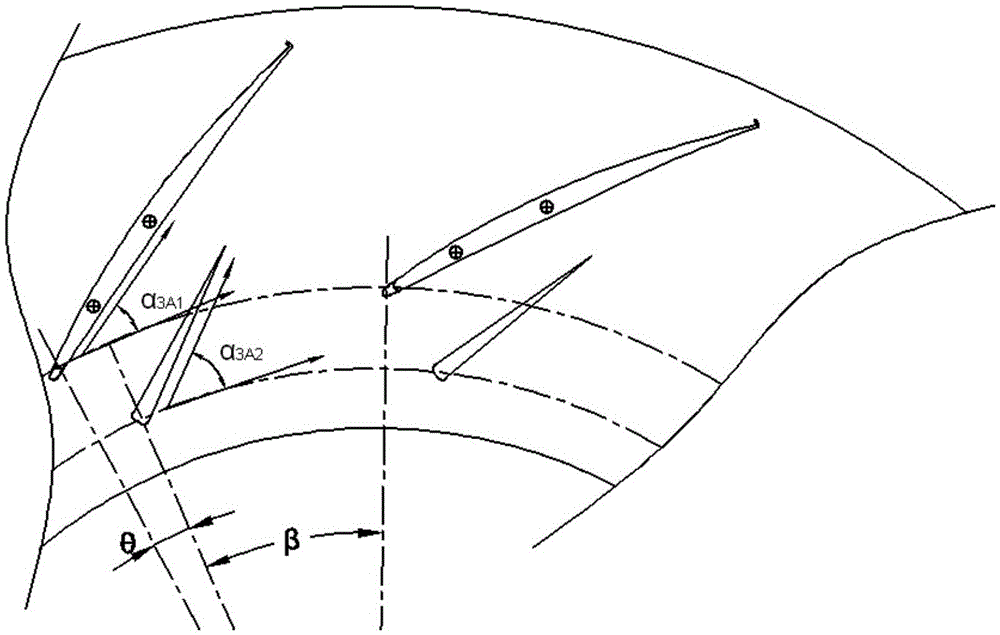

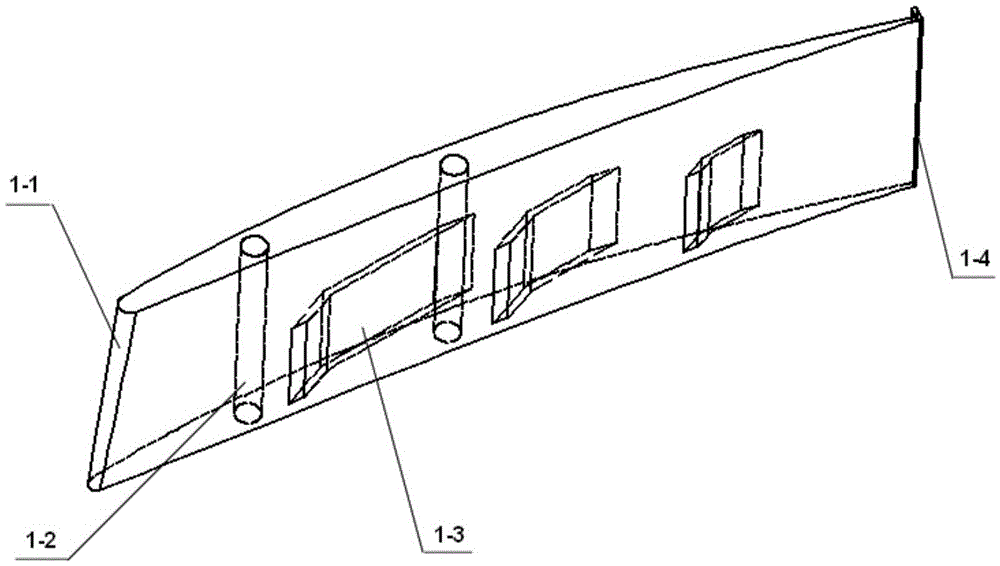

[0024] Such as figure 1 and 2 As shown, the diffuser of the centrifugal compressor includes long blades 1, short blades 2, disc 3 and wheel cover; there are 12 long blades 1, which are evenly distributed on the disc along the circumferential direction; two adjacent long blades 1 A short blade 2 is arranged in the flow channel, and the short blade 2 is close to the side of the suction surface of the long blade 1 . On the same cross-section, the radius of the circle centered on the center of the disc where the intercept point of the leading edge line of the suction surface of the short blade 2 is 15mm smaller than the radius of the circle where the intercept point of the leading edge line of the suction surface of the long blade 1 is located, and the suction surface of the short blade 2 The central angles between the intercept points of the leading edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com