Axial flow wind wheel with improved blades

A technology of axial flow wind and blades, which is applied to components of pumping devices for elastic fluids, non-variable pumps, pump components, etc., and can solve problems such as noise and efficiency deterioration, impeller efficiency reduction, and efficiency drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

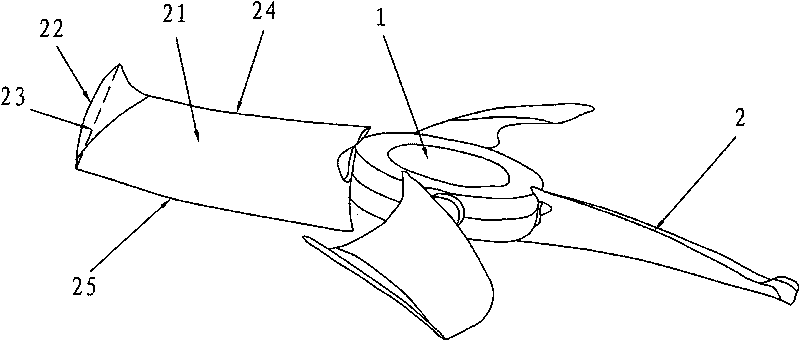

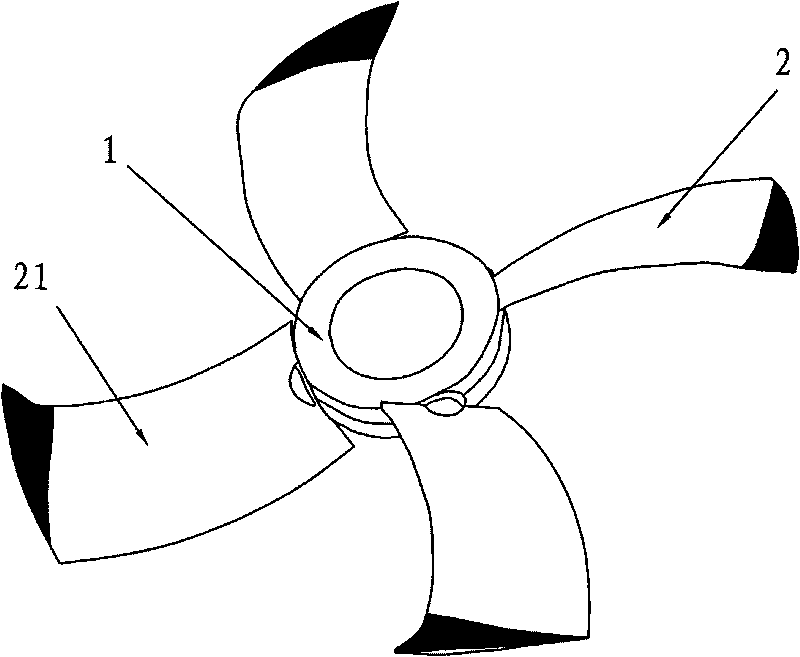

[0017] Such as figure 1 , figure 2 As shown, an axial-flow wind wheel with improved blades includes a hub 1 and blades 2, and the hub 1 and blades 2 are integrally formed. It gradually becomes smaller from the leading edge 24 to the trailing edge 25 . The overall shape of the blade 2 may not be changed, thereby controlling the leakage vortex at the leading edge of the outer circumference 22 and the air flow disturbance at the blade tip.

[0018] The maximum bending width is 20% of the distance from the hub 1 to the outer circumference 22 of the blade 2 .

[0019] The starting point of the bent portion is any position within the length of the 4 / 5 chord 23 from the outer circumference 22 of the blade 2 to the leading edge.

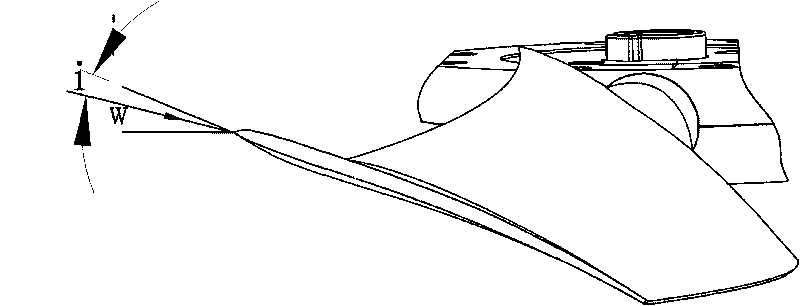

[0020] When the axial-flow wind wheel rotates, there is a lower pressure on the leeward side 21 of the leading edge 24 of the blade 1, resulti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com