Centrifugal impeller geometry optimization designing method capable of improving pump efficiency

A technology of geometric parameters and centrifugal impeller, which is applied to the components, pumps, and pump components of pumping devices for elastic fluids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

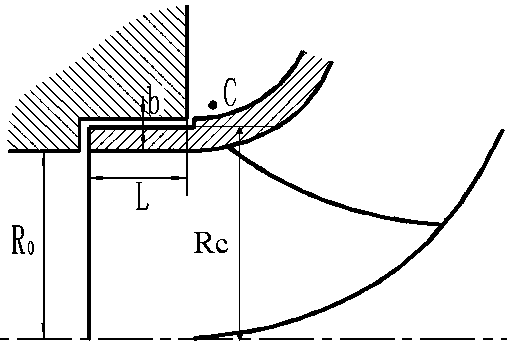

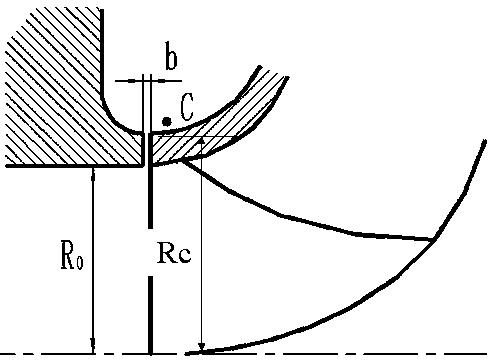

[0101] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0102] Convention notation:

[0103] Q T : The theoretical flow rate of the pump at the design point, m 3 / s;

[0104] Q: The flow rate of the pump at the design point, m 3 / s;

[0105] H: head of the pump at the design point, m;

[0106] n: design speed of the impeller, r / min;

[0107] ω: design rotational angular velocity of the impeller, 1 / s;

[0108] Ns: specific speed of the pump;

[0109] η, η h , η v , η m : Pump efficiency at design point, hydraulic efficiency, volumetric efficiency, mechanical efficiency;

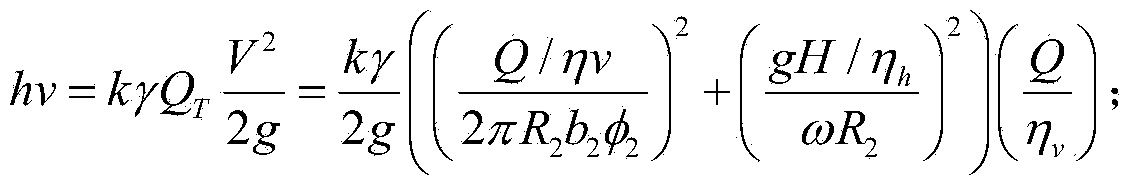

[0110] hv: the impact loss at the outlet of the impeller at the design point, W;

[0111] ΔN 1 : Disc friction loss of the pump at the design point, W;

[0112] V 2 ,V m2 ,V u2 : Absolute velocity of water flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com