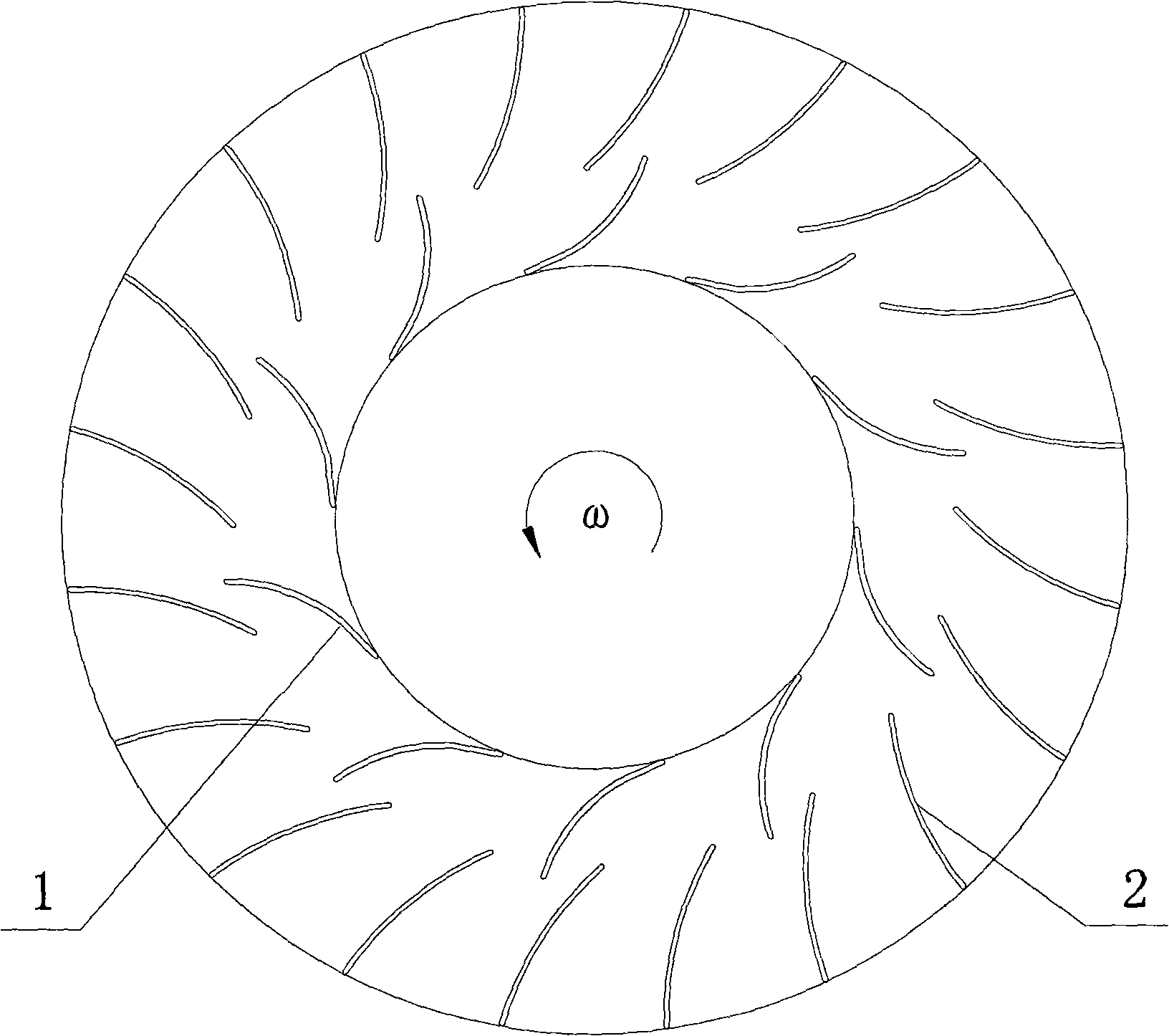

1/2 type tandem-blade type transonic speed centrifugal impeller

A centrifugal impeller and transonic technology, applied in non-variable pumps, machines/engines, components of pumping devices for elastic fluids, etc., can solve the problems of low efficiency of the whole stage and narrow stable operating range, and achieve Improve the efficiency of the whole stage, expand the surge margin, and increase the effect of blocking flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

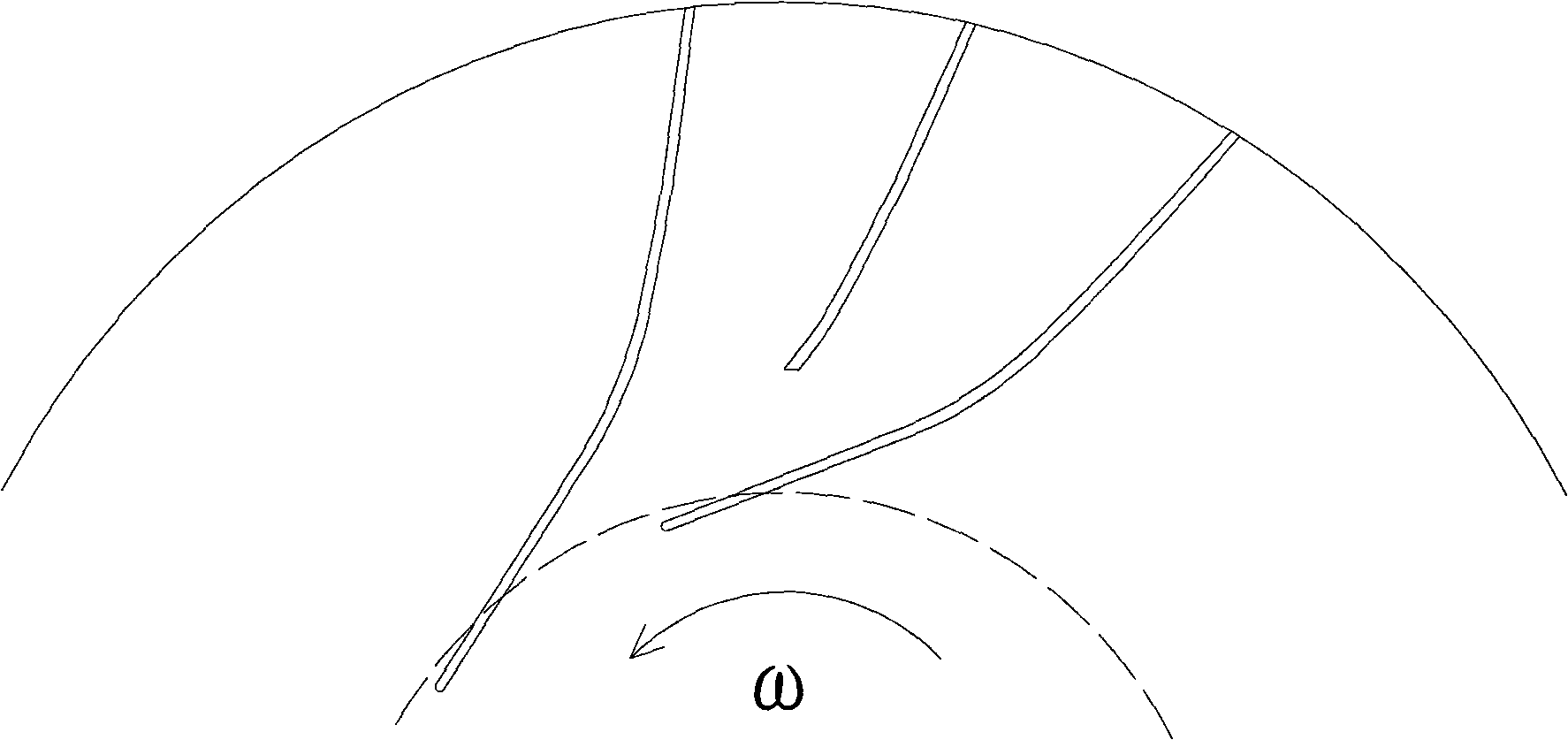

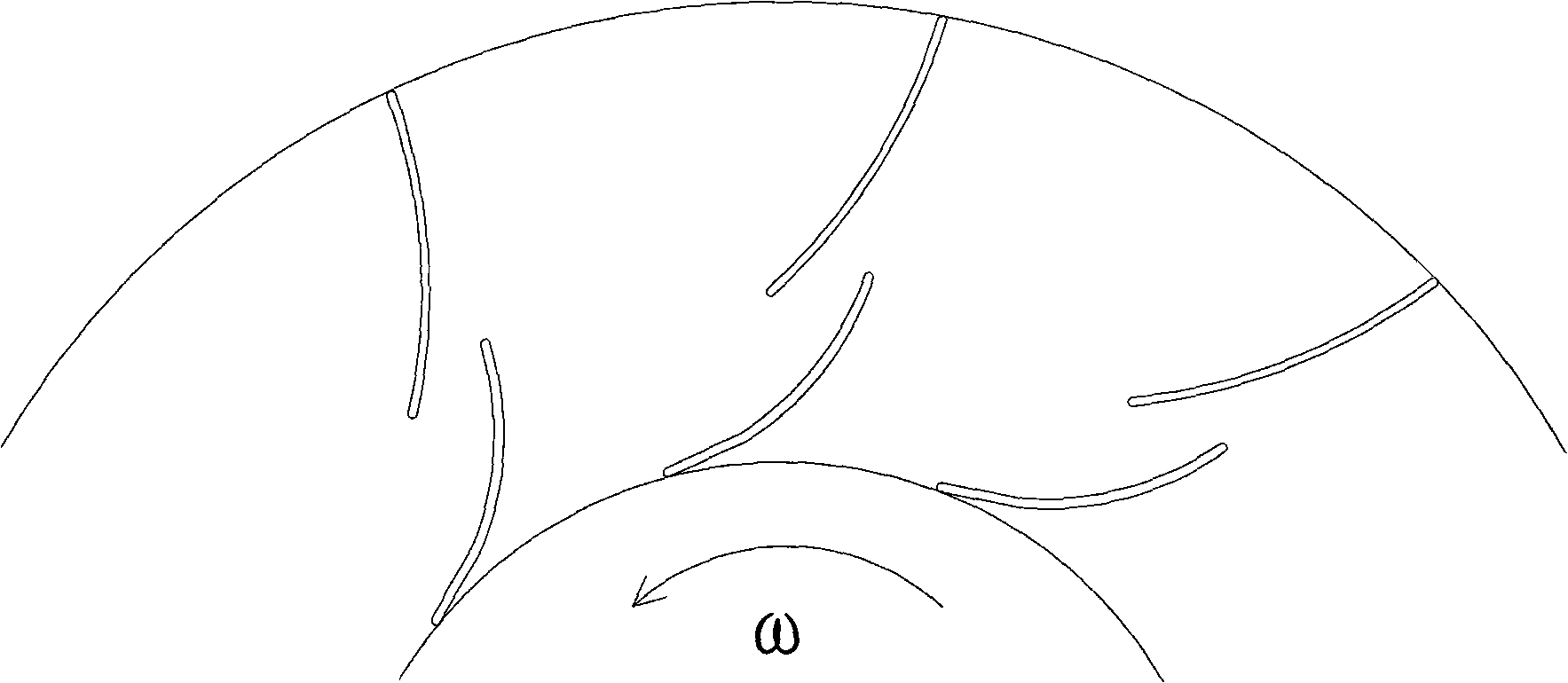

[0026] Embodiment 1, the rear row of blades 2 overlaps the front row of blades 1, and when the degree of overlap Δm=30%, the staggered degree Δθ of the rear row of blades and the front row of blades is 5%, and the relative division position m of the rear row of blades and the front row of blades 20%.

Embodiment 2

[0027] Embodiment 2, the inlet of the rear row of blades 2 is flush with the outlet of the front row of blades 1, that is, when Δm=0%, the staggered degree Δθ of the rear row of blades and the front row of blades is 25%, and the staggered degree Δθ of the rear row of blades and the front row of blades is 25%. The relative division position m is 50%.

Embodiment 3

[0028] Embodiment three, when rear row of blades 2 and front row of blades 1 overlap degree Δm=-5% (not overlapping), the degree of staggering Δθ of rear row of blades and front row of blades is 45%, the relative of rear row of blades and front row of blades The division position m is 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com