Centrifugal fan blade and centrifugal fan

A technology of centrifugal fan blade and blade shape, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc. It can solve the problems that are not conducive to improving the sound quality, reducing the efficiency of the fan, and reducing the noise of the unit, so as to reduce the impact loss , Improve aerodynamic efficiency and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and examples.

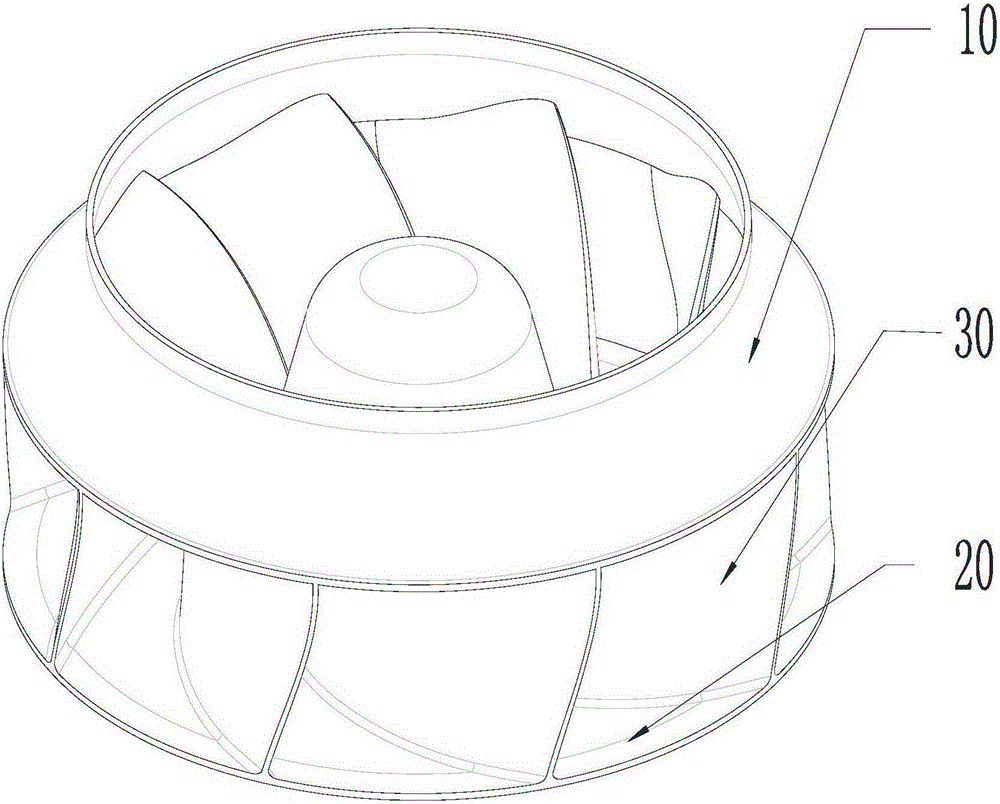

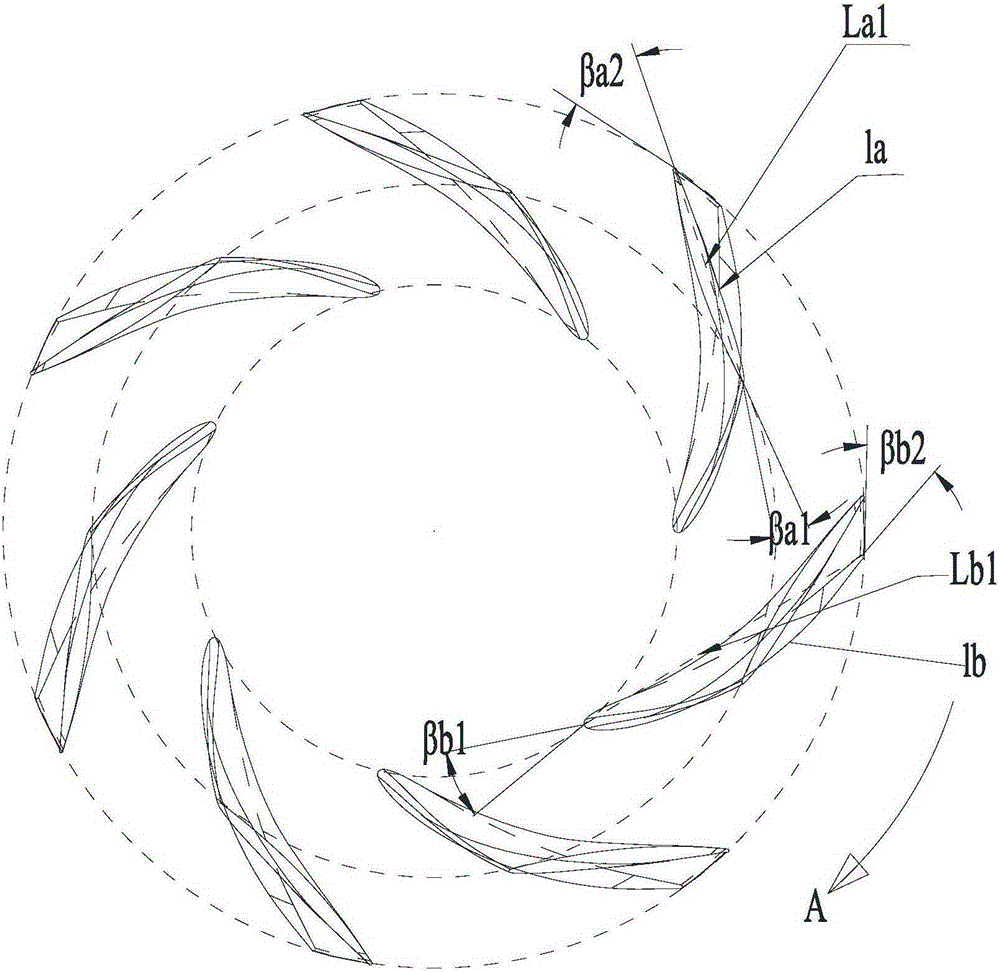

[0018] Such as figure 1 and figure 2 As shown, the centrifugal fan blade according to the present invention includes a front cover plate 10, a rear cover plate 20 and a plurality of blades 30 arranged between the front cover plate 10 and the rear cover plate 20, where the blades 30 and the front cover plate 10 are connected The inlet angle of the airfoil is βa1; the inlet angle of the airfoil at the connection between the blade 30 and the rear shroud 20 is βb1, where βa1<βb1. In the present invention, the airfoil inlet angle βa1 at the joint between the blade 30 and the front shroud 10 is smaller than the airfoil inlet angle βb1 at the joint between the blade 30 and the rear shroud 20, thereby reducing the impact loss of the airflow at the inlet and reducing noise , improve the aerodynamic efficiency of the fan blade.

[0019] Preferably, the airfoil i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com