Two-channel variable-section volute device with flow-guiding blades

A guide vane, dual-channel technology, used in engine components, machines/engines, internal combustion piston engines, etc., can solve problems such as wall friction loss, lack of improvement in airflow characteristics, and achieve good inheritance, easy control, and improved performance. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

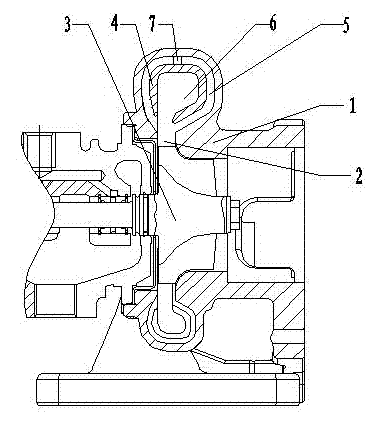

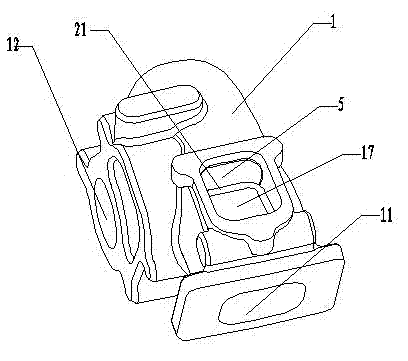

[0041] Example 1, such as image 3 , Figure 4 As shown, a double-channel variable-section volute device with guide vanes includes a volute 1, and the volute 1 is provided with a volute air inlet 11, a volute air outlet 12, and a volute air intake channel and Volute diffuser channel 2;

[0042] The volute air intake channel is provided with a pneumatic partition 13, and the aerodynamic partition 13 divides the volute air intake channel into the volute air intake inner channel 6 and the volute air intake outer channel 5;

[0043] The volute air intake outer flow channel 5 is located on the circumferential outer side of the volute air intake inner flow channel 6;

[0044] Vaneless nozzles 15 are respectively provided at the positions of the volute air intake outer flow channel 5 and the volute air intake inner flow channel 6 close to the volute diffuser passage 2;

[0045] A plurality of airfoil-shaped aerodynamic guide vanes 14 are evenly arranged in a circular shape near th...

Embodiment 2

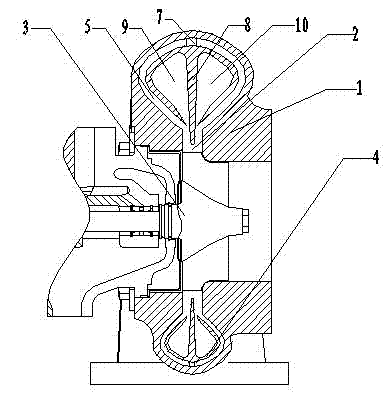

[0059] Example 2, such as Figure 6 As shown, in order to be applicable to a pulse supercharging system, such as a six-cylinder engine, in the above-mentioned embodiment 1, the volute air inlet 11 can also be designed as a double air inlet: comprising the air inlet 24 on the left side of the volute and the volute Right air intake 25.

[0060] Such as Figure 7 As shown, the volute intake inner flow channel 6 is provided with a pulse inner flow channel rib 8, and the pulse inner flow channel rib 8 divides the volute intake inner flow channel 6 into the left pulse inner flow channel 9 And the inner runner 10 of the pulse on the right side.

[0061] The left pulse inner flow channel 9 and the right pulse inner flow channel 10 are respectively connected with the left air inlet 24 of the volute and the right air inlet 25 of the volute.

[0062] The cross-section of the pulse internal flow channel rib 8 is tapered, and the pulse internal flow channel rib 8 is connected with the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com