Heat pipe with composite wick structure

a technology of heat pipes and wicks, applied in indirect heat exchangers, lighting and heating apparatus, etc., can solve the problems of insufficient and achieve the effect of improving the efficiency of work fluid backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

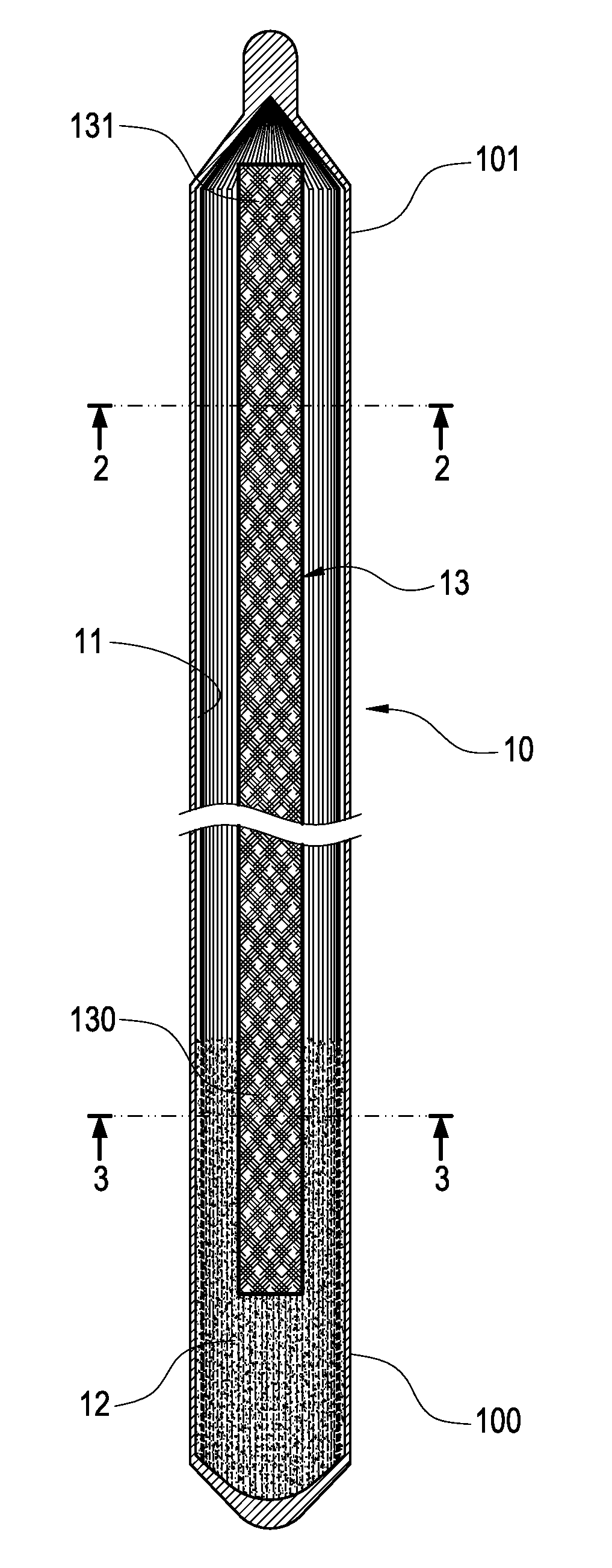

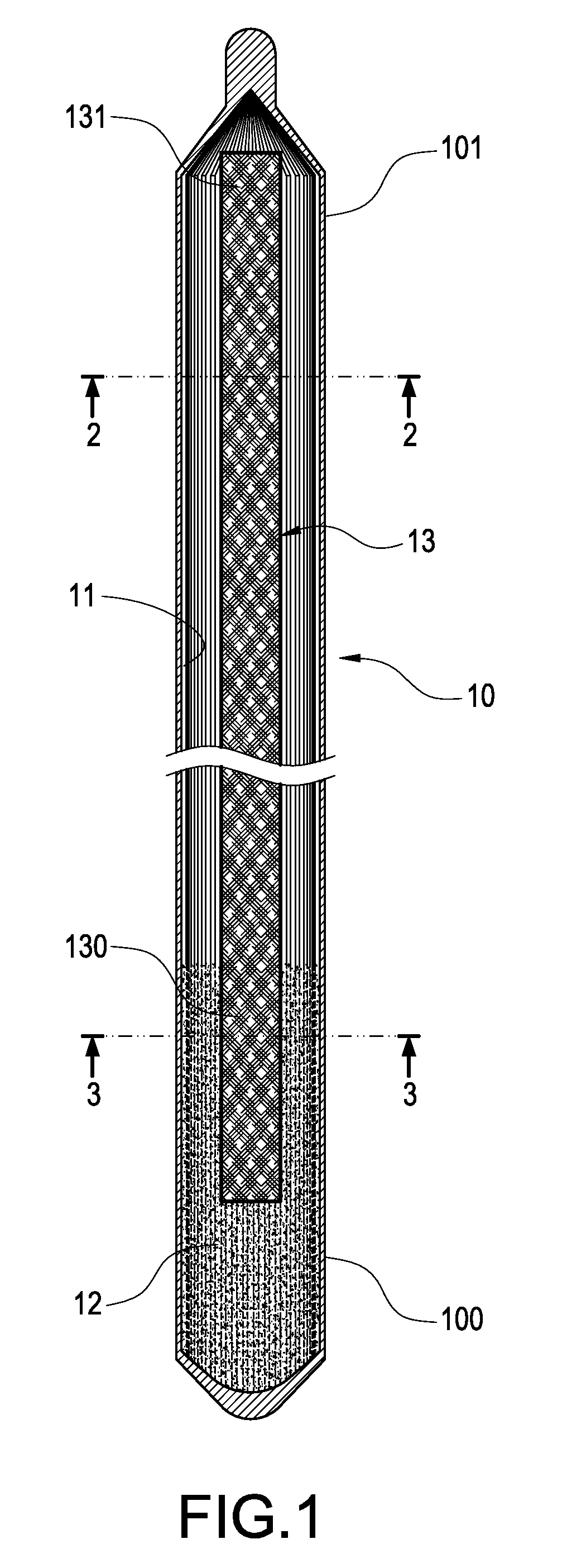

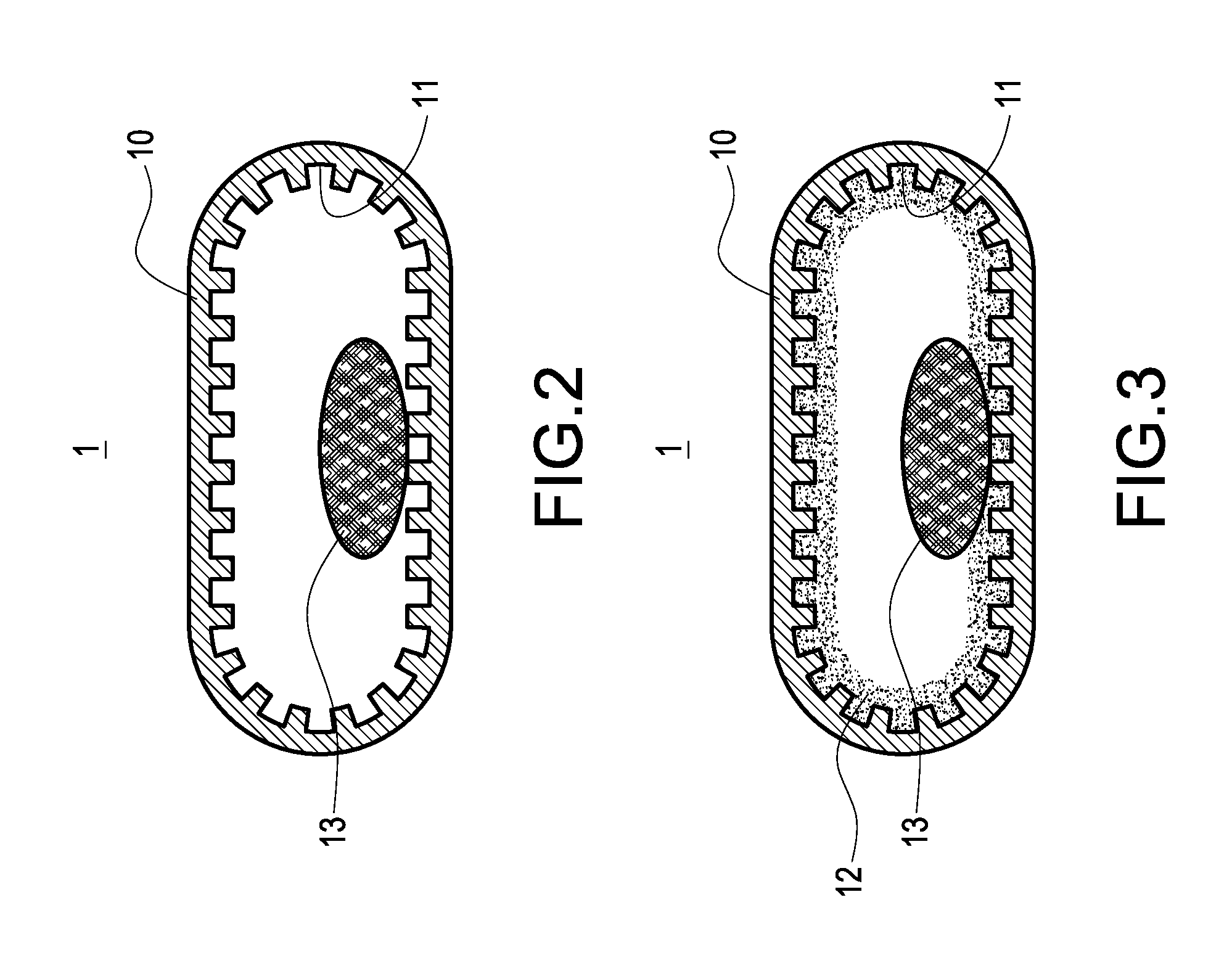

[0015]Please refer to FIGS. 1 and 4. The heat pipe of the invention includes a tube 10, a grooved wick 11, a porous wick 12 and a fiber wick 13.

[0016]An evaporating portion 100 and a condensing portion 101 are defined in the tube 10. In the shown embodiment, the evaporating portion 100 and the condensing portion 101 are separately located at two ends of the tube 10. Of course, there may be a plurality of evaporating portions 100 or condensing portions 101. The grooved wick 11 is longitudinally and entirely disposed on an inner wall of the tube 10 and communicates the evaporating portion 100 and the condensing portion 101. A work fluid (not shown) contained in the tube 10 may flow back from the condensing portion 101 to the evaporating portion 100 through the grooved wick 11.

[0017]The porous wick 12 is made of sintered powder. The porous wick 12 is only disposed on the inner wall of the evaporating portion 100 and covers the grooved wick 11 in the evaporating portion 100.

[0018]Please...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com