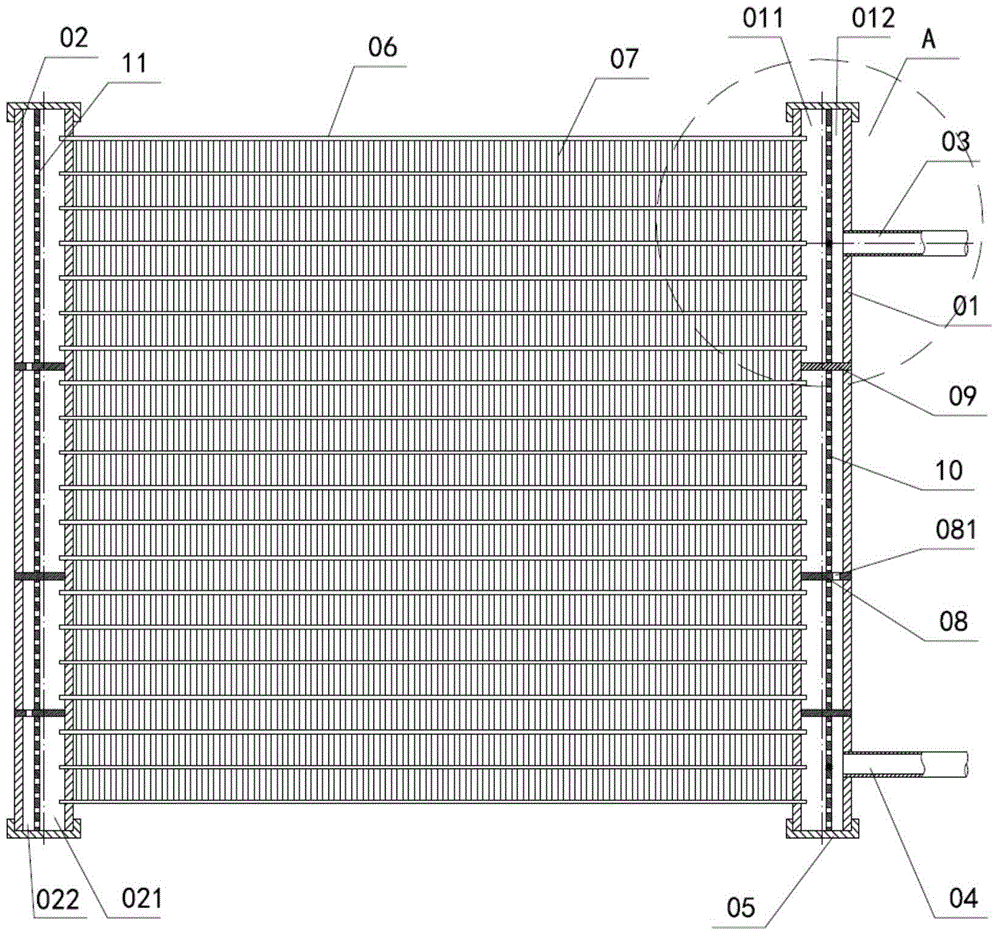

Microchannel heat exchanger capable of uniformly distributing refrigerant flow

A technology of micro-channel heat exchanger and refrigerant flow, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc. Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

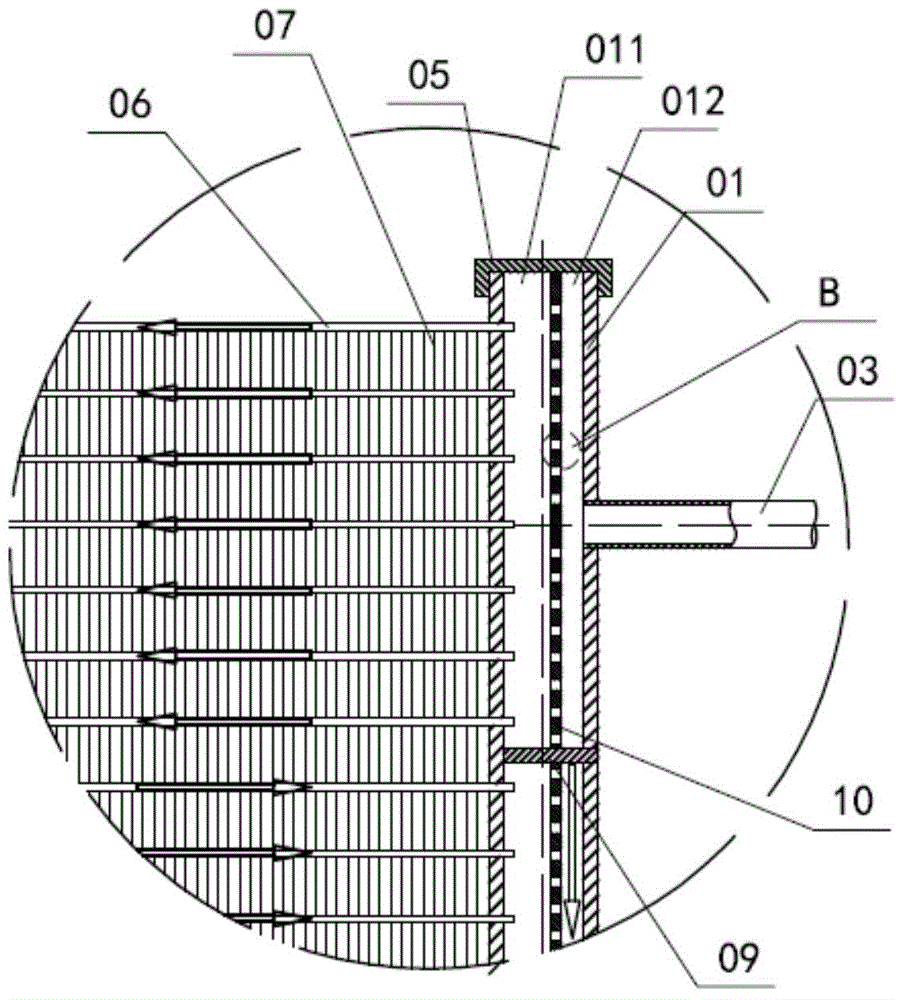

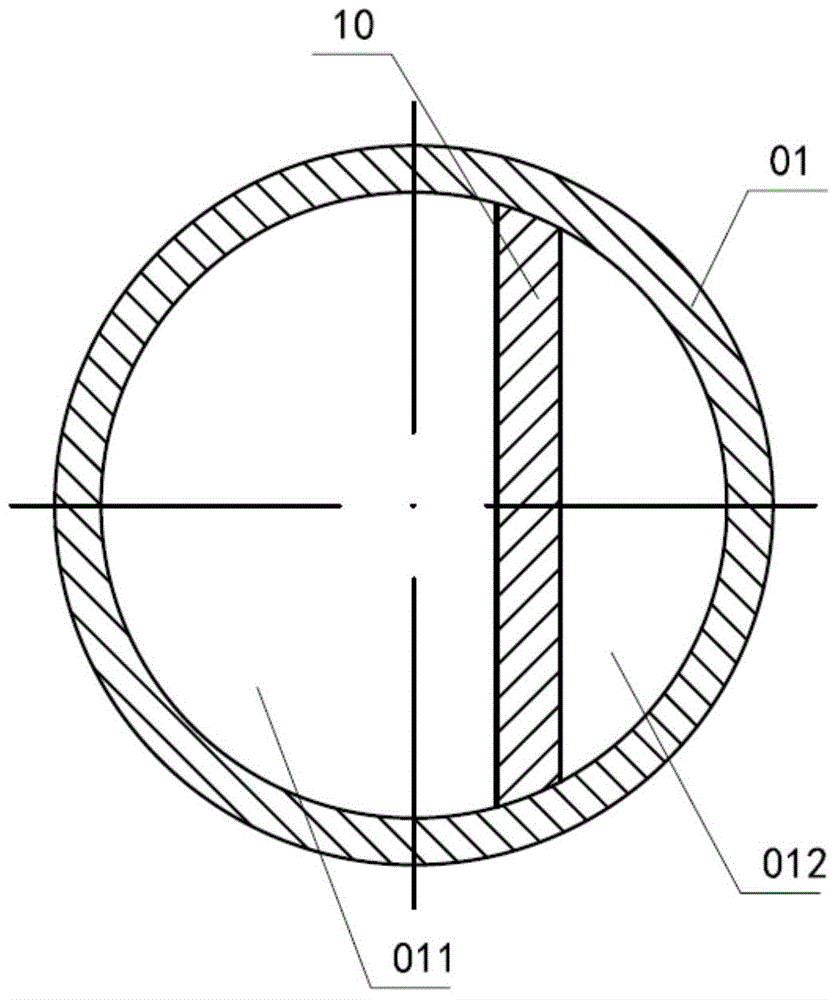

[0041] For the schematic diagram of the cross-sectional structure of the first air collecting pipe and the schematic diagram of the cross-sectional structure of the second air collecting pipe in Embodiment 1, see image 3 and Figure 4 , the first flow plate 10 divides the first air collecting pipe 01 into the first inner cavity part 011 and the first outer cavity part 012 close to the microchannel flat tube 06; the second flow plate 11 separates the second air collecting pipe 02 into Close to the second inner cavity part 021 and the second outer cavity part 022 of the microchannel flat tube 06 .

[0042] figure 2 For the schematic diagram of the local structure of B, see Figure 5 , The through hole 13 of the equalizer plate is a cylindrical hole, and the two ends of the cylindrical hole are provided with chamfers. Both ends of the through hole of the equalizing plate are provided with chamfers, which can play a drainage role and improve the flow efficiency of the working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com