Changeable outlet flow section turbine jet nozzle ring

A turbine nozzle and deflector technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of large volume, complex structure and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Hereinafter, the technical content of the present invention will be further described through embodiments and in conjunction with the accompanying drawings.

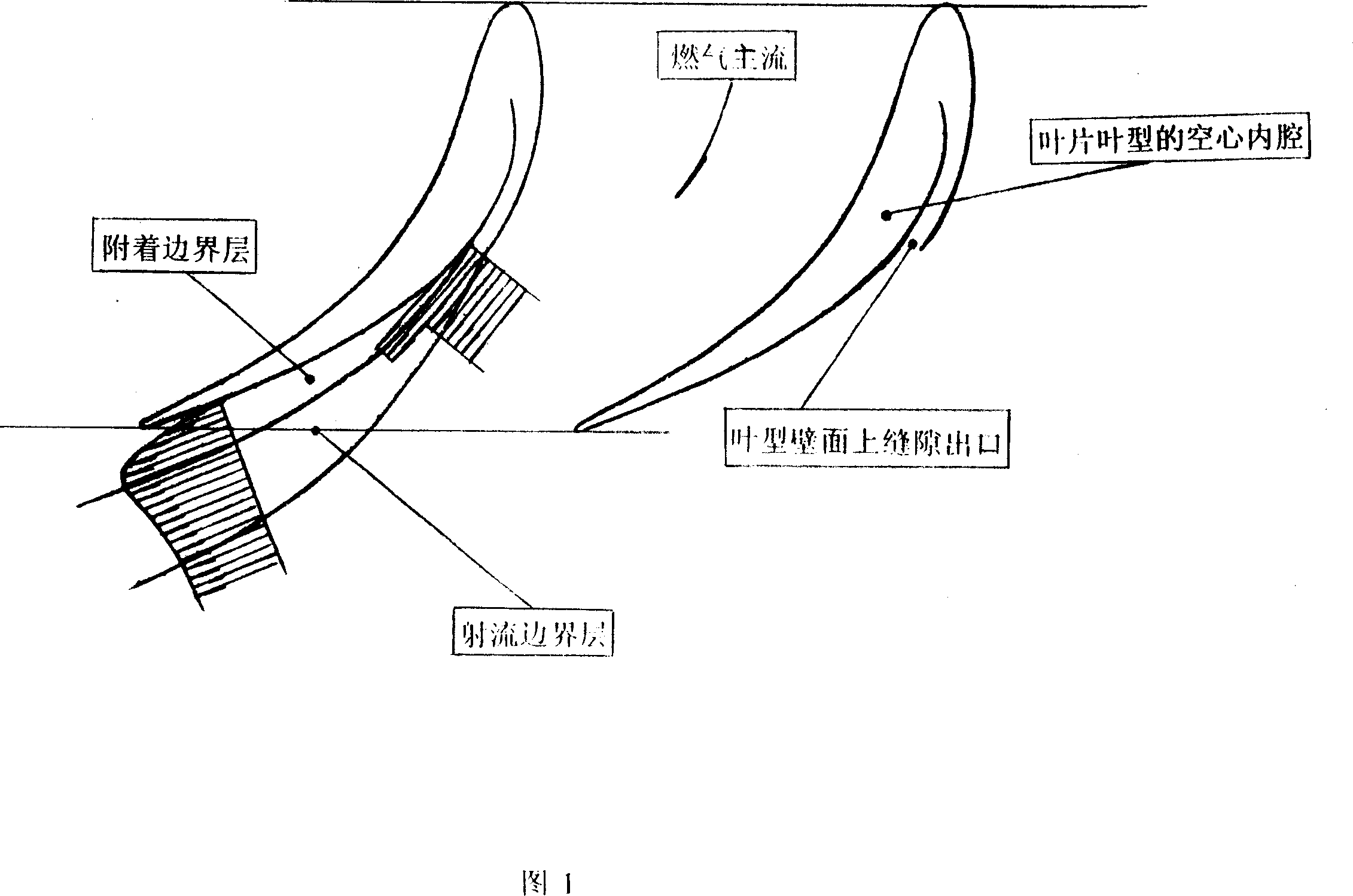

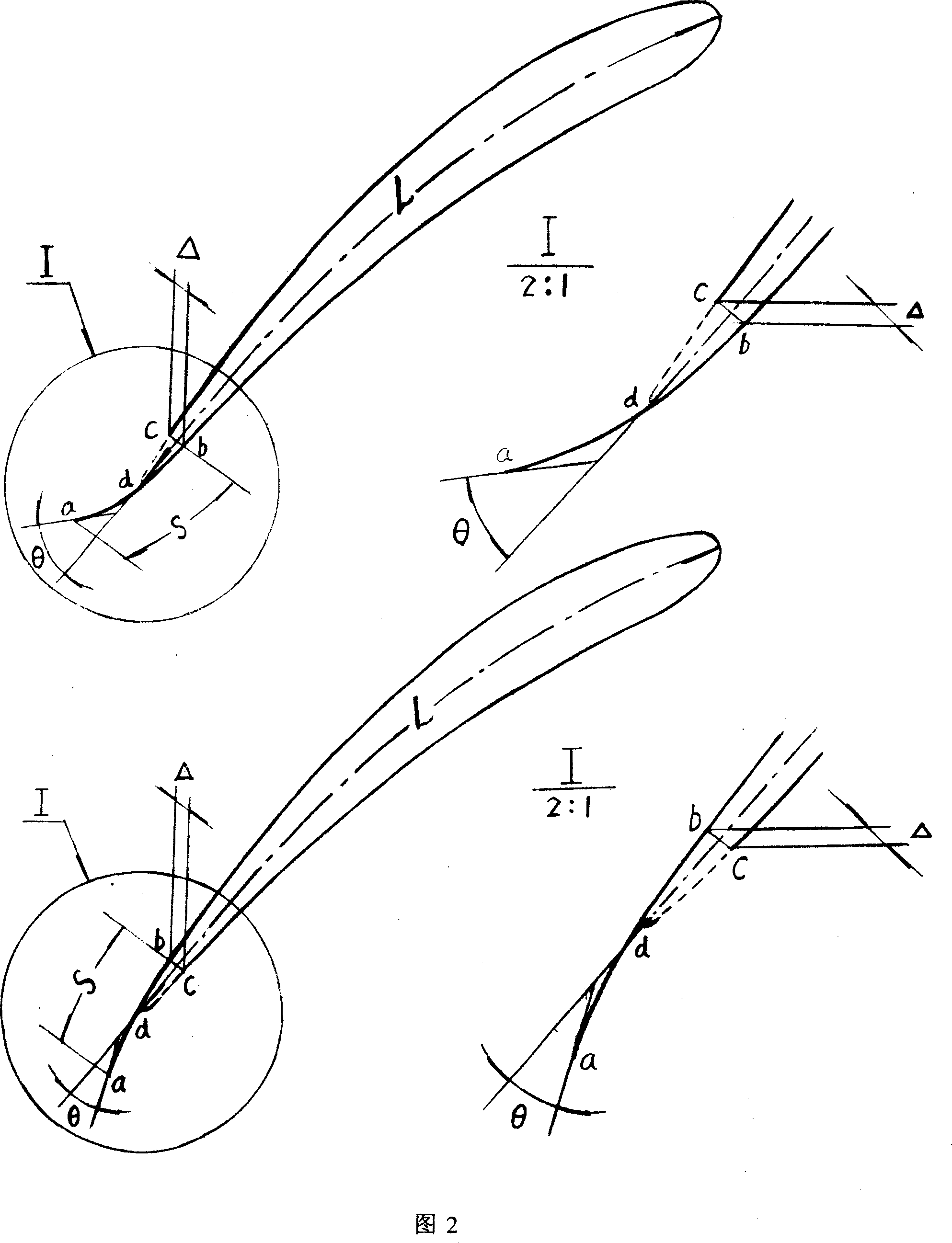

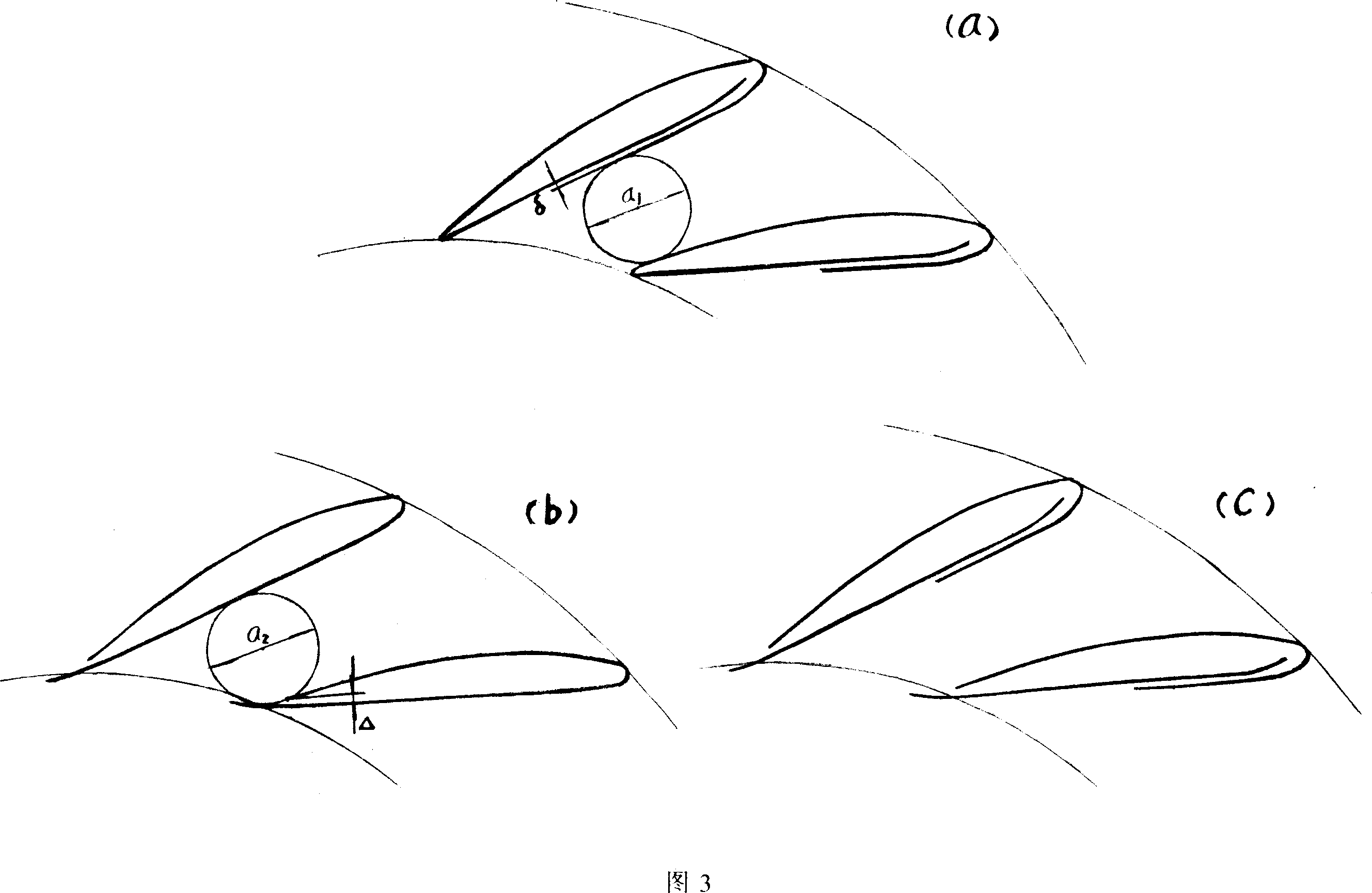

[0054] As mentioned above, the technical core of the present invention is the use of external compressed air to pass through the hollow cavity of the nozzle blade, through the flow slot cut by the airfoil profile and / or the trailing edge (the trailing edge slot is attached with The arc-shaped baffle) blows the main flow of gas in the nozzle ring cascade flow channel and / or the cascade outlet downstream, so that the air flow mixed with the slit jet and the main flow will deflect at the nozzle ring outlet in a direction different from the original main flow direction, causing The change of outlet airflow angle (ie, outlet flow cross-sectional area). Through the pressure regulating valve to regulate the supply pressure of the compressed air, the outlet airflow angle will be changed as required to meet the demand for boos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com