A drilling and completion method for hot dry rock robotic explosive hydraulic fracturing

A composite fracturing and hydraulic fracturing technology, which is applied in earthwork drilling, wellbore/well components, and production fluids, etc., can solve problems such as difficulty in proportion and quantity control, failure to meet combustion conditions, and potential safety hazards. Reduce the risk of heat transfer short circuit, optimize the crack network, and reduce the effect of operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

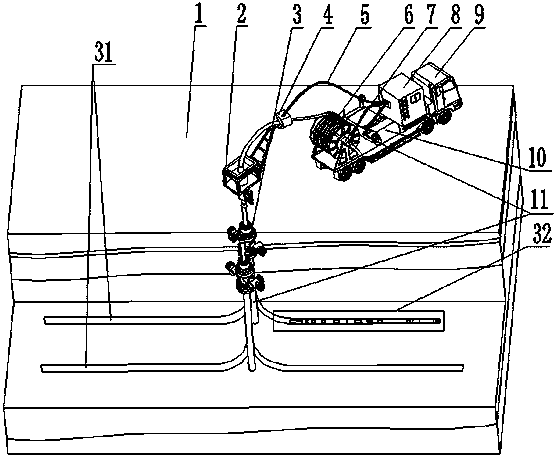

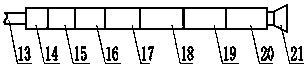

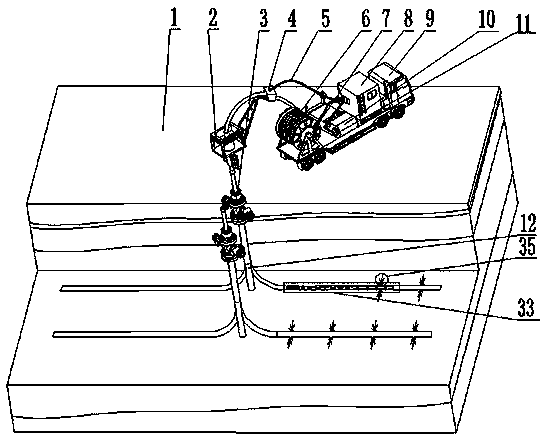

[0037] This embodiment provides a hot dry rock robot explosive hydraulic composite fracturing drilling and completion system, including a ground control system, a robot 17, a drilling execution system, an explosive fracturing execution system, a hydraulic fracturing execution system, a directional execution system, and a heavy Into the execution system; the robot 17 is respectively connected to the drilling execution system, the explosive fracturing execution system, the hydraulic fracturing execution system, the directional execution system, and the reentry execution system. The robot is used for drilling, explosive fracturing, hydraulic Data collection and control of fracturing.

[0038] The surface port control system includes a data processing center, a surface data acquisition sensor, a drilling and completion controller, a surface signal transceiver 4, a blowout preventer 3, a coiled tubing wellhead device 2, a coiled tubing operating vehicle 9, an input device, and a storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com