A motor for driving drilling tools downhole

A technology of motors and motor casings, applied in the field of motors, can solve problems such as increased operating costs, accelerated drilling speed, and large losses, and achieves the effects of high energy conversion efficiency, improved work efficiency, and high adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

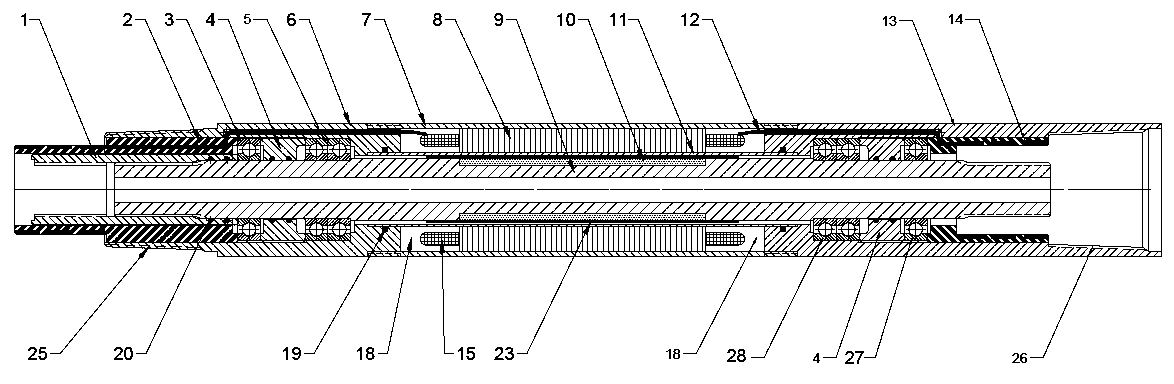

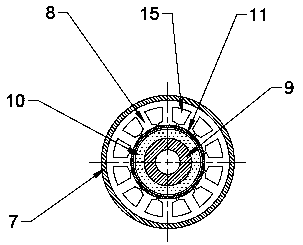

[0036] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, a motor for driving downhole drilling tools. The overall structure of the motor is slender cylindrical. The motor includes a motor housing 7, a stator, a rotor shaft 9, an upper rotor support bearing 5, a lower rotor support bearing 28, and an upper bearing The seat 6, the lower bearing seat 13, the male conductive ring 2, the female conductive ring 14, the connecting spline sleeve 1, the upper spline positioning bearing 3, and the lower spline positioning bearing 27.

[0037] The rotor shaft 9 has a hollow cylindrical structure, the hollow part of the rotor shaft 9 is a mud channel 21, and a connecting spline sleeve 1 is provided outside the front end of the rotor shaft 9, and the connecting spline sleeve 1 is provided There is a mud passage sealing ring 20, which seals the mud in the mud passage 21, and places the mud into the lubrication part of the bearing, which affects the life of the bearing...

Embodiment 2

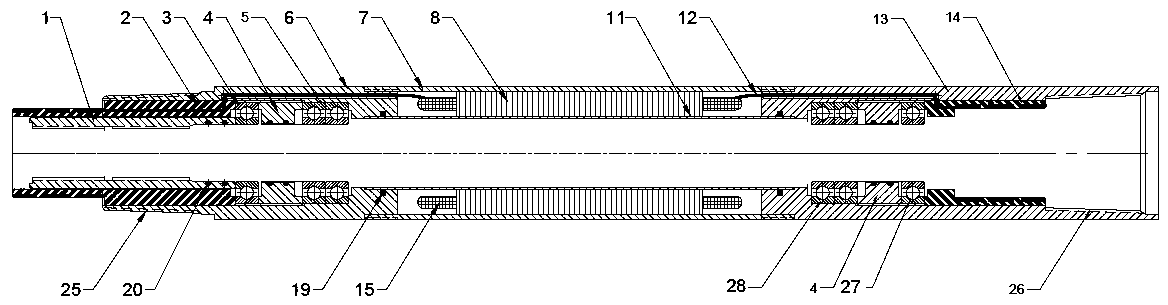

[0049] Such as Image 6 , Figure 7 with Figure 8 As shown, two motors of the present invention are connected together. The number of connected motors of the present invention can also be one or more. The two motors of the present invention are the first module motor 100 and the second module motor 101. The motor of the present invention is designed and produced in accordance with standardization and modularization. The first modular motor 100 and the second modular motor 101 have the same size and structure, and become an integral motor after being connected to drive the drill bit 17 to rotate.

[0050] A motor for driving downhole drilling tools. The overall structure of the motor is a slender cylindrical shape. The motor includes a motor housing 7, a stator, a rotor shaft 9, an upper rotor support bearing 5, a lower rotor support bearing 28, an upper bearing seat 6, Lower bearing seat 13, male conductive ring 2, female conductive ring 14, connecting spline sleeve 1, upper spli...

Embodiment 3

[0064] Such as Picture 9 , Picture 10 with Figure 4 As shown, a motor for driving downhole drilling tools. The overall structure of the motor is slender cylindrical. The motor includes a motor housing 7, a stator, a rotor shaft 9, an upper rotor support bearing 5, a lower rotor support bearing 28, and an upper bearing The seat 6, the lower bearing seat 13, the male conductive ring 2, the female conductive ring 14, the connecting spline sleeve 1, the upper spline positioning bearing 3, and the lower spline positioning bearing 27.

[0065] The rotor shaft 9 has a hollow cylindrical structure, the hollow part of the rotor shaft 9 is a mud channel 21, and a connecting spline sleeve 1 is provided outside the front end of the rotor shaft 9, and the connecting spline sleeve 1 is provided There is a mud passage sealing ring 20, which seals the mud in the mud passage 21, and places the mud into the lubrication part of the bearing, which affects the life of the bearing.

[0066] The fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com