Foam cyclic utilization method used for under balance drilling

A foam and foam-stabilizing technology, which is applied in drilling compositions, chemical instruments and methods, earthwork drilling, etc., can solve the problem of large floor space for natural defoaming, inability to handle a large amount of foam, and high consumption of defoaming agents, etc. To solve the problem, to achieve the effect of convenient on-site operation, lower drilling operation cost and strong foaming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

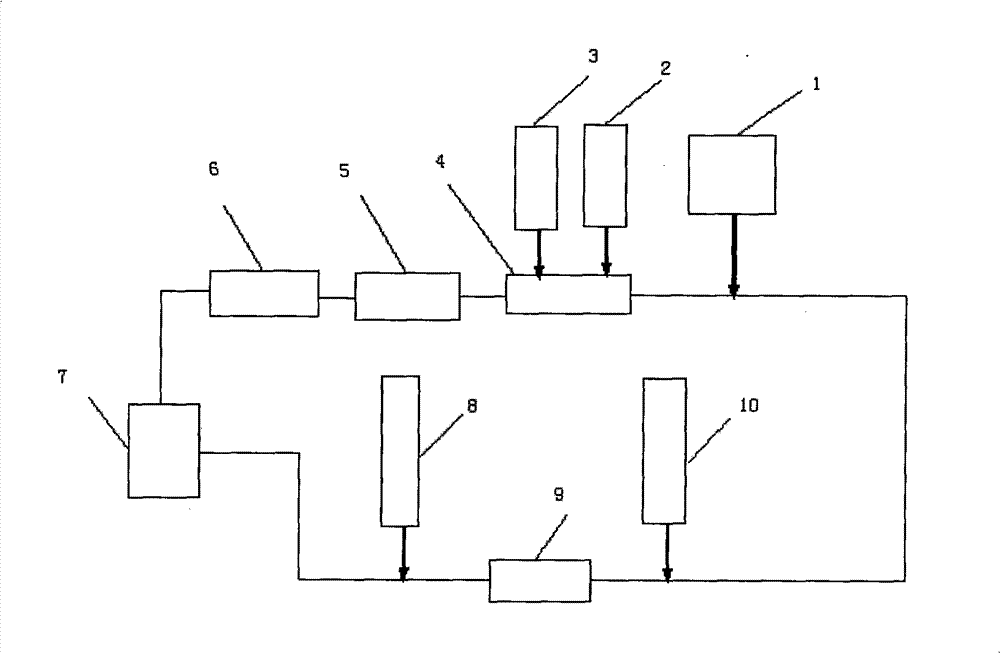

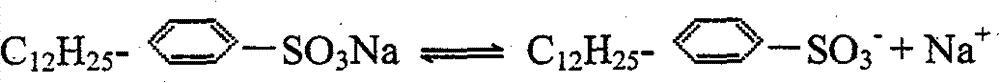

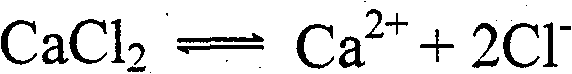

[0023] Embodiment 1, brittle foam base fluid circulation experiment

[0024] The brittle foam base formula is prepared by weight: 0.6% ABS+tap water. The prepared brittle foam base liquid is injected into the base liquid tank 2 and the base liquid replenishment tank 1, and the air intake volume and the foam base liquid volume of the air supply system 3 and the base liquid tank 2 are respectively adjusted on the ground, and foam generation is monitored through the foam parameter monitoring system 5 The foam generated in the foam generator 4, after the foam quality and half-life in the foam generator 4 meet the requirements, open the well entry valve 6 to inject foam into the well 7, and after the foam carrying cuttings returns to the wellhead, it is added through the additive addition system A8 CaCl with a mass concentration of 20% to 30% 2 solution to realize the first defoaming; the liquid after defoaming removes cuttings through the debris removal system 9, and then adds Na...

Embodiment 2

[0027] Embodiment two, stable foam cycle experiment

[0028] The formulation of stable foam base liquid is prepared by weight: 0.4% ABS+0.3% SDS+0.2% XC+0.2% CMC+tap water. Adjust the air intake and foam base fluid volume on the ground, monitor the foam quality and half-life through the foam parameter monitoring system, and open the well valve to inject foam into the well after the foam quality and half-life meet the requirements, and the foam carrying cuttings will circulate back to the wellhead , add CaCl with a mass concentration of 40% through additive addition system A 2 Solution, to achieve the first defoaming, the defoaming liquid removes cuttings through the debris removal system, and then adds Na with a mass concentration of 50% through the additive addition system B 2 CO3 solution to restore the foaming ability of the blowing agent, and the foam liquid enters the foam generator again to re-foam. After the foam quality and half-life meet the requirements, it is pumpe...

Embodiment 3

[0031] Embodiment three, three-phase foam circulation experiment

[0032] The formula of the three-phase foam base liquid is prepared by weight: 0.5% SDS + 0.2% XC + 0.3% CMC + 5.0% bentonite + tap water. Adjust the air intake and foam base fluid volume on the ground, monitor the foam quality and half-life through the foam parameter monitoring system, and open the well valve to inject foam into the well after the foam quality and half-life meet the requirements, and the foam carrying cuttings will circulate back to the wellhead , add CaCl with a mass concentration of 50% through additive addition system A 2 Solution, to achieve the first defoaming, the defoaming liquid removes cuttings through the debris removal system, and then adds Na with a mass concentration of 50% through the additive addition system B 2 CO 3 Solution, restore the foaming ability of the foaming agent, the foam liquid enters the foam generator again to re-foam, and after the foam quality and half-life me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com