Gas control method for large-mining-height working face of high gas coal seam

A technology with large working face and large mining height, which is applied in the direction of gas discharge, mining equipment, earthwork drilling and mining, etc., can solve the problems of large gas emission, tension of working face recovery and connection, and the failure of working face gas to meet the standard, so as to reduce gas The effect of reducing the amount of outflow, increasing the speed of mining connection, and avoiding gas accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

[0032] The described gas control method for high gas coal seam working face with large mining height comprises the following steps:

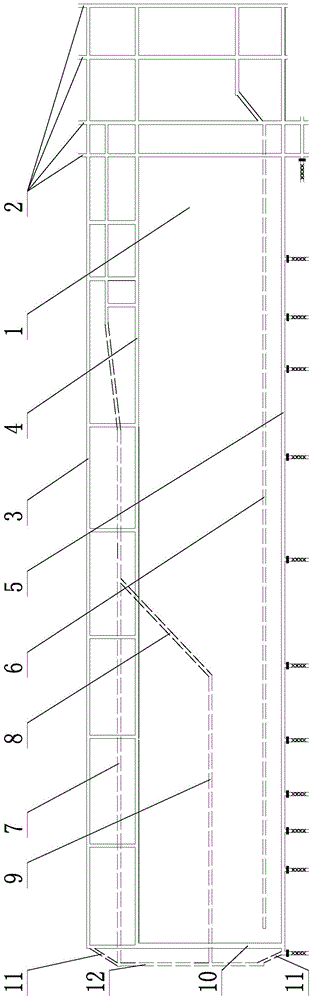

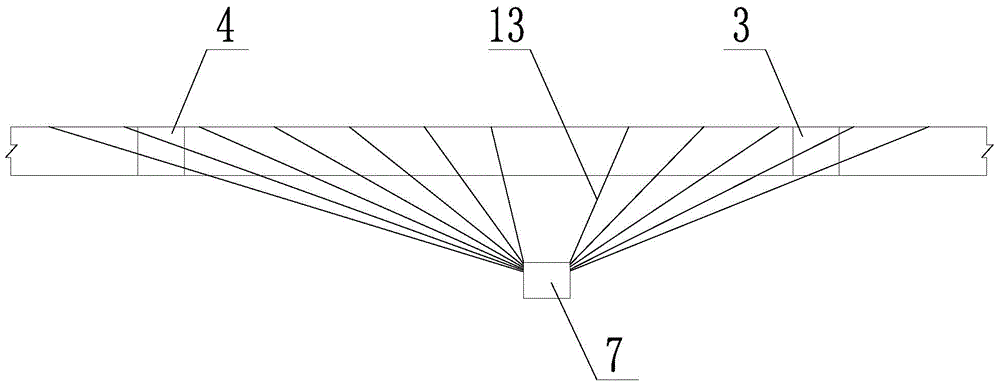

[0033] Step 1: During the excavation process of the current working face 1, starting from the main lane 2, along the middle position of the bottom plate of the adjacent working face return air lane 3 and the current working face transport lane 4, a first bottom extraction lane 7 is dug ahead in parallel;

[0034] Step 2: Arrange through-layer drilling holes 13 upward through the first bottom extraction roadway 7, and carry out gas pre-extraction operation on the coal body where the roadway to be driven is located, and conduct geological structure detection at the same time to guide the roadway excavation;

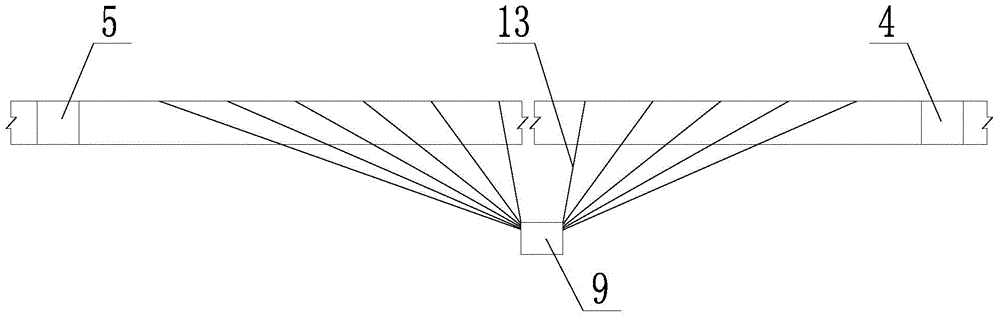

[0035] Step 3: stagger the incision hole 10 outside and then excavate an incision fundus extraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com