Vacuumizing system suitable for mass spectrometer

A vacuum pumping system and mass spectrometer technology, applied in the field of mass spectrometers, can solve the problems of long sample waiting time, large volume, and bulky mass spectrometer, and achieve the advantages of shortening the waiting time for sample injection, reducing the gas path structure, and improving the detection efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

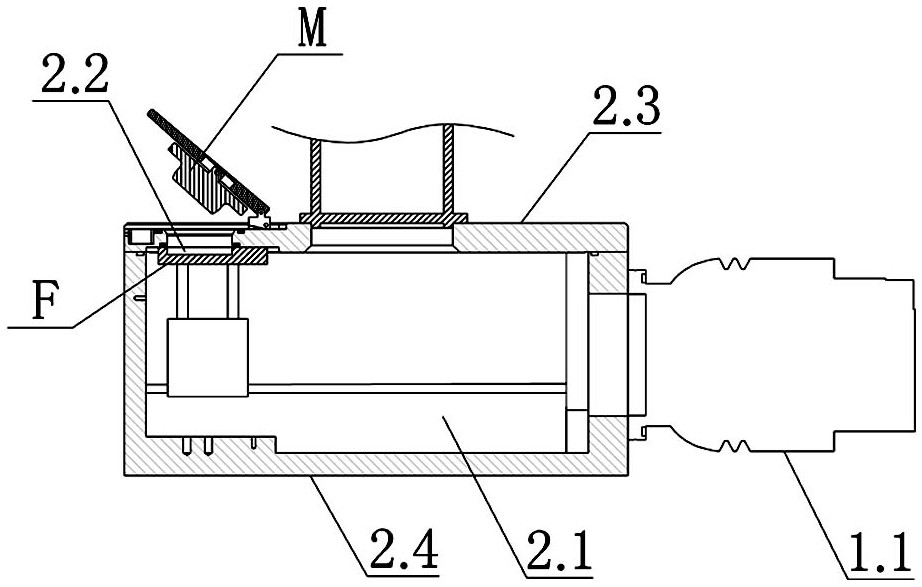

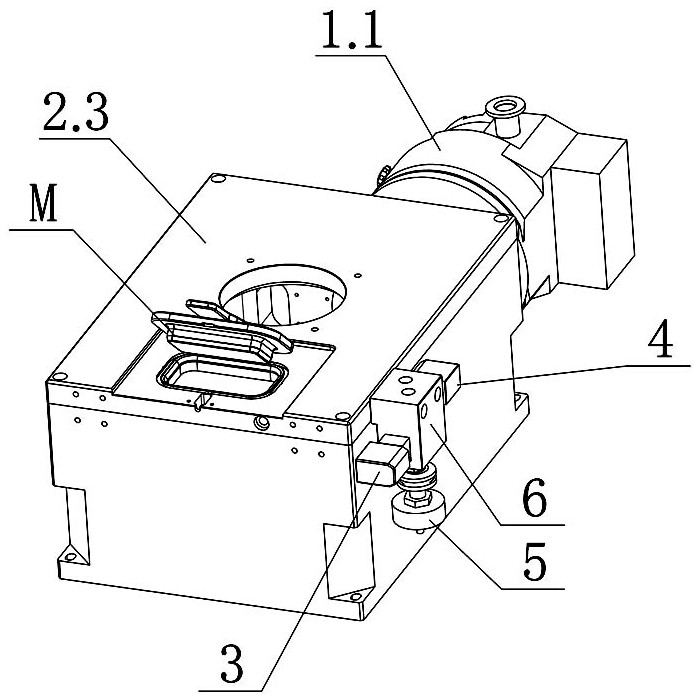

[0039] Such as Figure 1-3 As shown, the vacuum pumping system suitable for a mass spectrometer described in this embodiment includes a first pumping unit and a second pumping unit, and the first pumping unit includes a molecular pump 1.1 and a mechanical pump 1.2 (working pressure at 10 -2 Pa), the pumping port of the molecular pump 1.1 is connected with the vacuum chamber 2.1 of the mass spectrometer; before the detection (that is, the sample is detected by the mass spectrometer), use the mechanical pump 1.2 to pre-pump the molecular pump 1.1, and then start the molecular pump 1.1 , using the molecular pump 1.1 to draw negative pressure on the vacuum chamber 2.1 (the mechanical pump 1.2 continues to work), so that the negative pressure of the vacuum chamber 2.1 maintains the high vacuum degree required by the sample (about 10 -6 mbar);

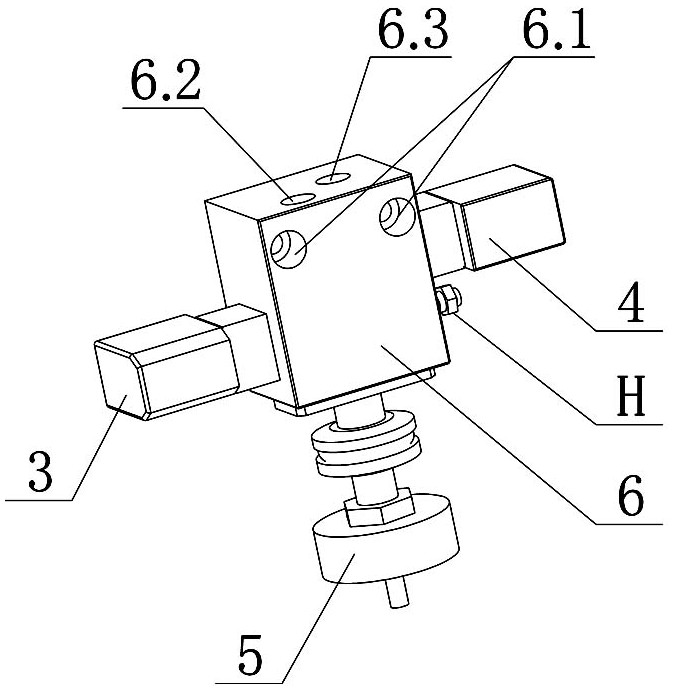

[0040]The second pumping unit includes a vacuum air circuit, an inlet valve 3 and a pre-extraction valve 4, one end of the vacuum air ci...

Embodiment approach 2

[0056] The difference between the vacuum pumping system described in this embodiment and the first embodiment is that the vacuum pumping system further includes a negative pressure buffer unit. Specifically: as Figure 11 As shown, the negative pressure buffer unit includes a buffer chamber 7.1 and a buffer valve 7.2. The first interface of the buffer chamber 7.1 communicates with the suction port of the mechanical pump 1.2 through the first pipeline, and the second interface of the buffer chamber 7.1 communicates with the air inlet of the mechanical pump 1.2 through the second pipeline. The transition chamber 2.2 is connected, and the other end of the second pipeline is sealed and inserted into the connection port on the sealing cover M plate corresponding to the transition chamber 2.2. The buffer valve 7.2 (preferably a two-position two-way electric valve) is connected to the on the pipeline.

[0057] In actual installation, the buffer valve 7.2 can also be integrally insta...

Embodiment approach 3

[0062] The difference between the vacuum system described in this embodiment and the second embodiment is that the negative pressure buffer unit is different. Specifically: as Figure 12 As shown, the negative pressure buffer unit includes a buffer chamber 7.1 and a buffer valve 7.2 (the buffer valve 7.2 is preferably a two-position two-way solenoid valve). The first interface of the buffer chamber 7.1 communicates with the vacuum chamber 2.1 through the pre-pumping valve 4. The second interface of 7.1 communicates with the transition chamber 2.2 through the buffer valve 7.2;

[0063] One interface of the pre-pumping valve 4 communicates with the fourth passage 6.9, making it communicate with the vacuum chamber 2.1 through the fourth passage 6.9, the second connecting hole 6.3, and the second connecting passage 6.5; the other port of the pre-pumping valve 4 It communicates with the buffer cavity 7.1 through the connecting tube, and the other interface of the buffer cavity 7.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com