Moving type roots and slide valve vacuum unit

A technology of vacuum unit and slide valve vacuum pump, which is applied in the direction of machine/engine, liquid fuel engine, rotary piston type machinery, etc. Long service life, wide application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

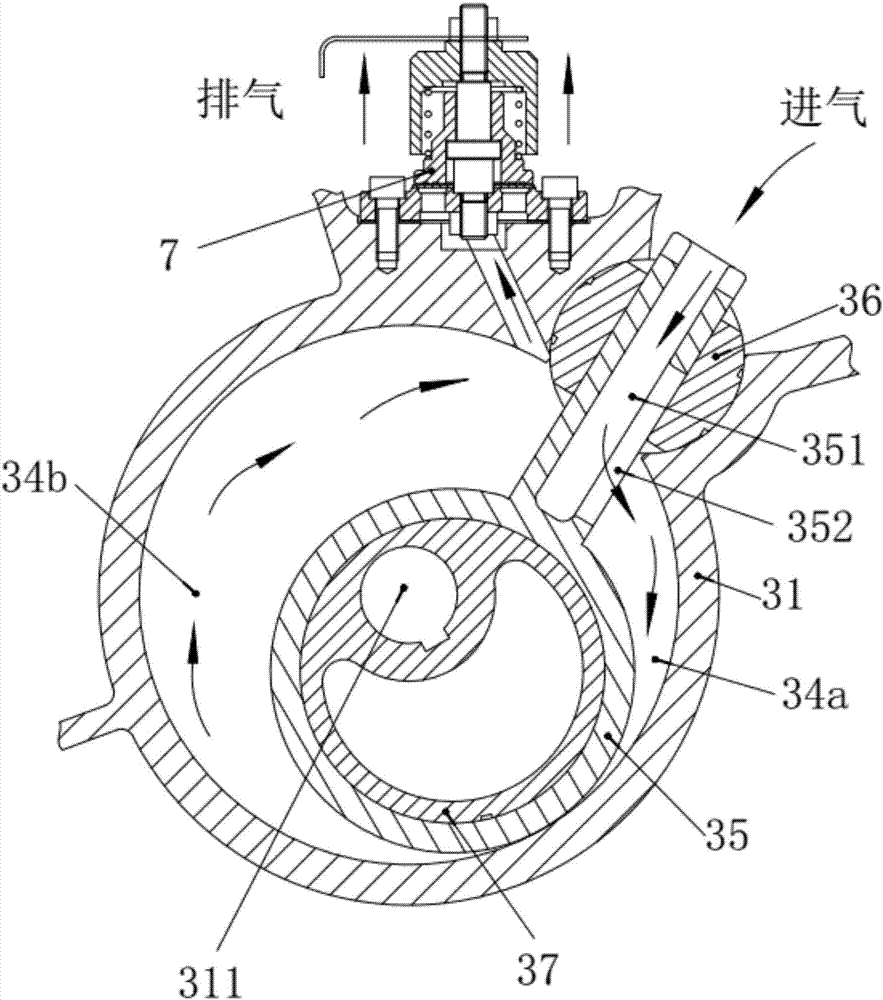

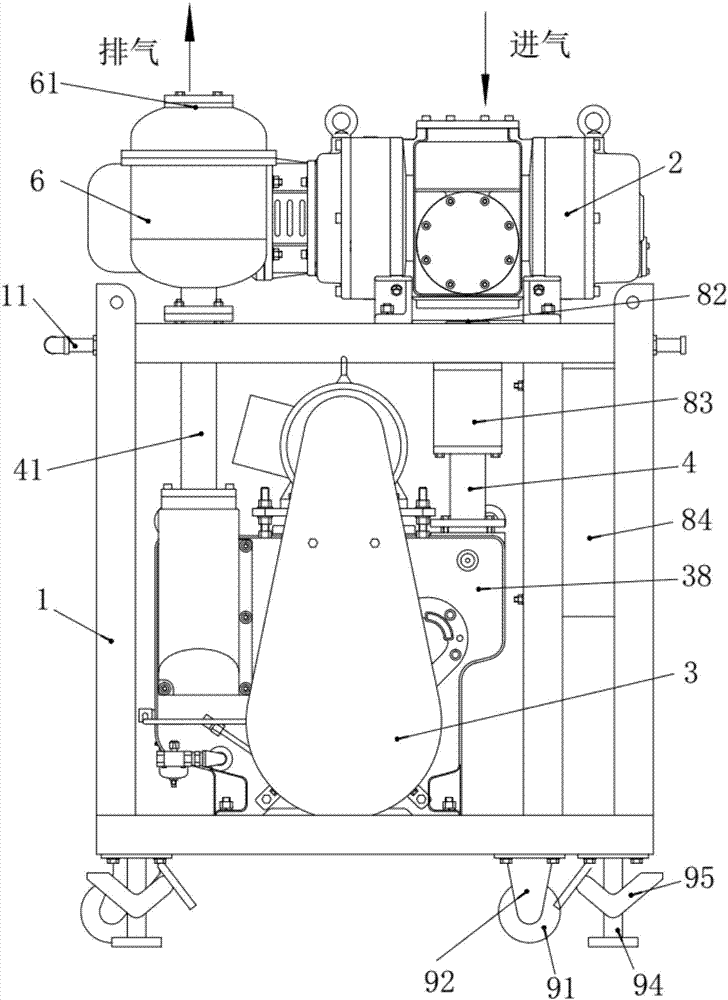

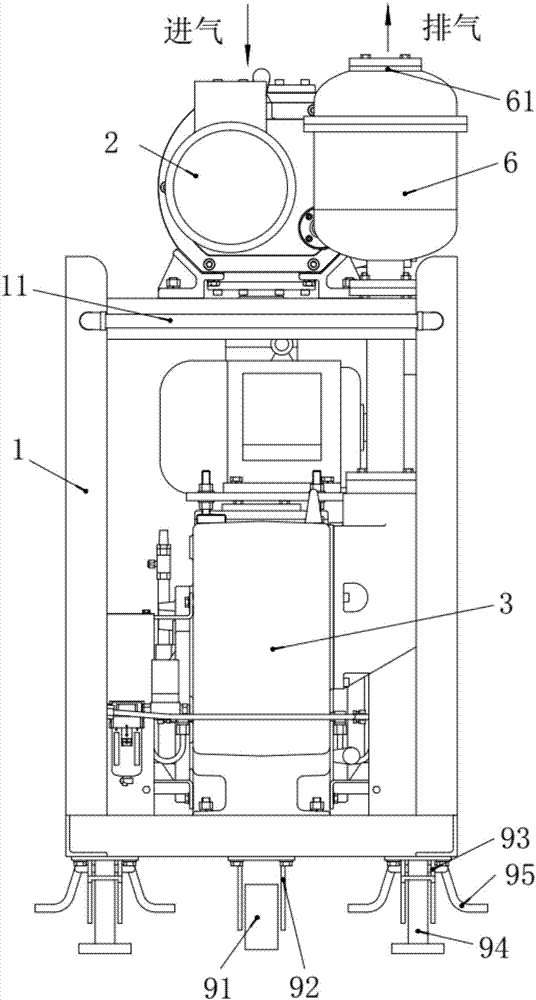

[0031] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-Figure 6 ,

[0032] A mobile Roots slide valve vacuum unit, including a frame 1 and a pump set installed on the frame 1, a sliding device is arranged under the frame 1, and the pump set includes a Roots vacuum pump 2 and a slide valve vacuum pump 3. The Roots vacuum pump is located above the slide valve vacuum pump, and the Roots vacuum pump is connected to the slide valve pump air inlet 32 of the slide valve vacuum pump through the connecting pipeline 4, and an electromagnetic pressure differential inflation valve 83 is installed on the connecting pipeline 14 The slide valve vacuum pump is provided with an oil tank 38, and an oil liquid 39 is stored in the oil tank 38; an oil mist eliminator 6 is connected above the oil tank 38, and a final air outlet 61 is provided on the oil mist eliminator 6; An electric control box 84 for contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com