A progressive shield type gas pressure relief and extraction method

A gas and drainage technology, applied in the field of progressive shielding gas pressure relief and drainage, can solve the problems of increasing the influence range and pressure relief effect of through-layer drilling, poor applicability of drilling pressure relief and permeability enhancement technology, etc. The effect of decompression and anti-reflection, avoiding the elimination of blank strips, and improving the driving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

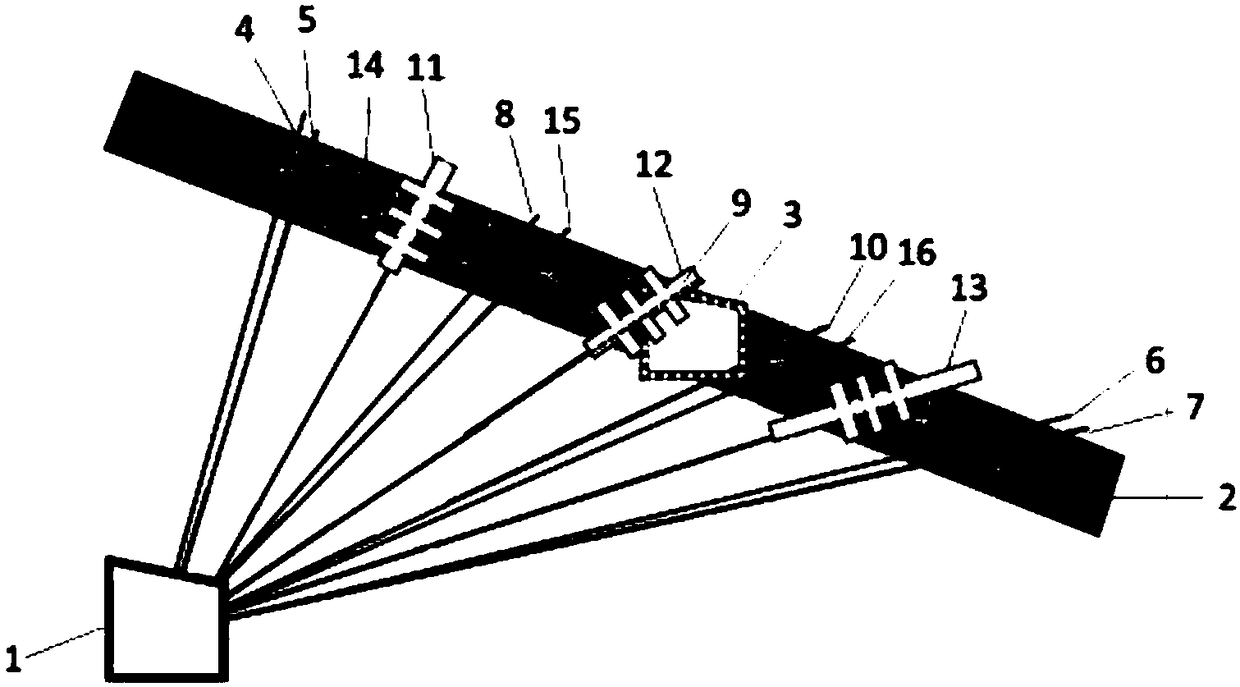

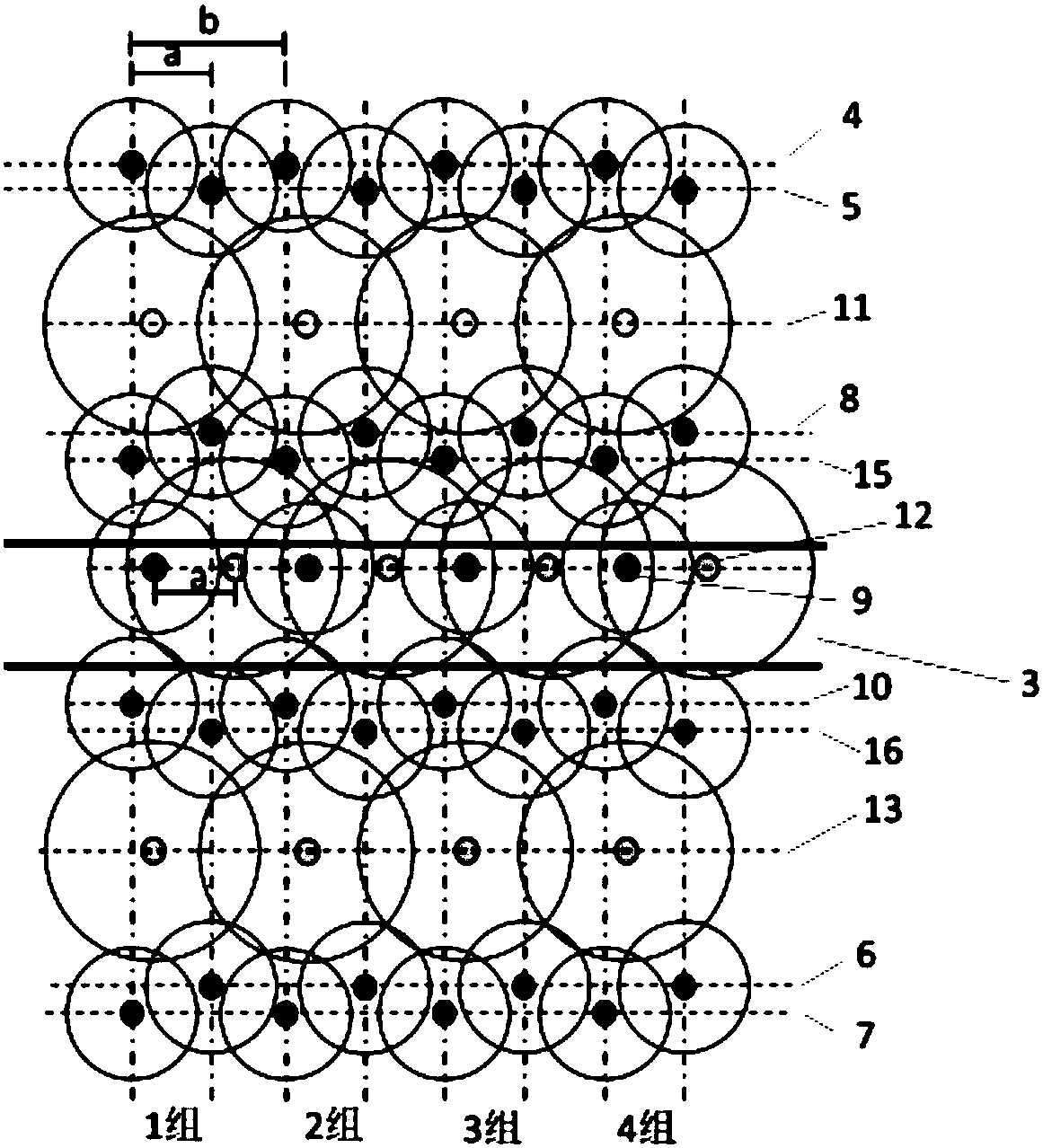

[0020] The progressive shielding gas pressure relief and drainage method of the present invention includes the following steps:

[0021] a. From the floor roadway 1 to the coal seam 2 on both sides of the upper coal roadway 3, the upper and lower partition holes shall be constructed through the layer; the upper and lower partition holes shall each be at least two, and the holes between the upper partition holes The gap and the hole spacing a between the upper partition holes are 2.5-3.5m respectively.

[0022] b. Pre-drain the gas from the upper partition hole and the lower partition hole. The upper partition hole separates the gas from the coal roadway and the upper side gas moves to the coal road 3, and the lower partition hole separates the gas from the coal roadway and lowers the gas to the coal roadway. 3 transport;

[0023] c. Between the upper partition hole and the lower partition hole, a plurality of through-layer shield holes are constructed at intervals from the floor roa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com