A method of operating a vacuum system with a pre-extraction device

A technology of vacuum pumping system and operation method, which is applied in vacuum smelting vacuum pumping system and vacuum degassing field, which can solve problems such as poor load effect, increased failure rate, and large temperature drop of molten steel, so as to reduce temperature and dust content, reduce Maintenance cost, the effect of ensuring the temperature of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

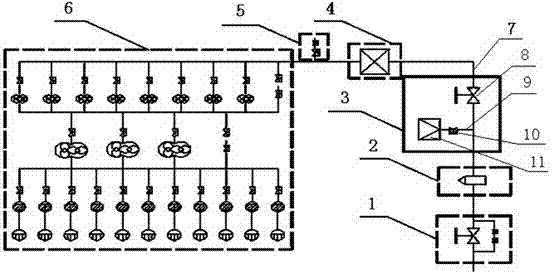

[0015] Refer to attached figure 1 , a vacuum system with a pre-extraction device, including a vacuum opening and closing module 1, a coarse filtration module 2, a fine filtration module 4, a breaking module 5, a degassing module 6 and a main pipeline 7, a vacuum opening and closing module, a coarse filtration module Module, fine filter module, and degassing module are connected through the main pipeline in sequence, and its special feature is that a pre-extraction device 3 is provided between the coarse filter module 2 and the fine filter module 4, and the pre-extraction device 3 includes a valve A8, a branch The pipeline 9, the valve B10 and the tank body 11, the valve A8 is placed on the main pipeline 7 between the coarse filtration module 2 and the fine filtration module 4, and the main pipeline 7 between the valve A8 and the coarse filtration module 2 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com