Non-blasting construction method of hard-rock tunnel in city

A construction method and technology for tunnels, which are applied to tunnels, earth-moving drilling, mining equipment, etc., can solve the problems of inefficient short-distance tunnels, large investment, low work efficiency, etc. The effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A non-explosive construction method for urban hard rock tunnels, comprising the following three essential core steps:

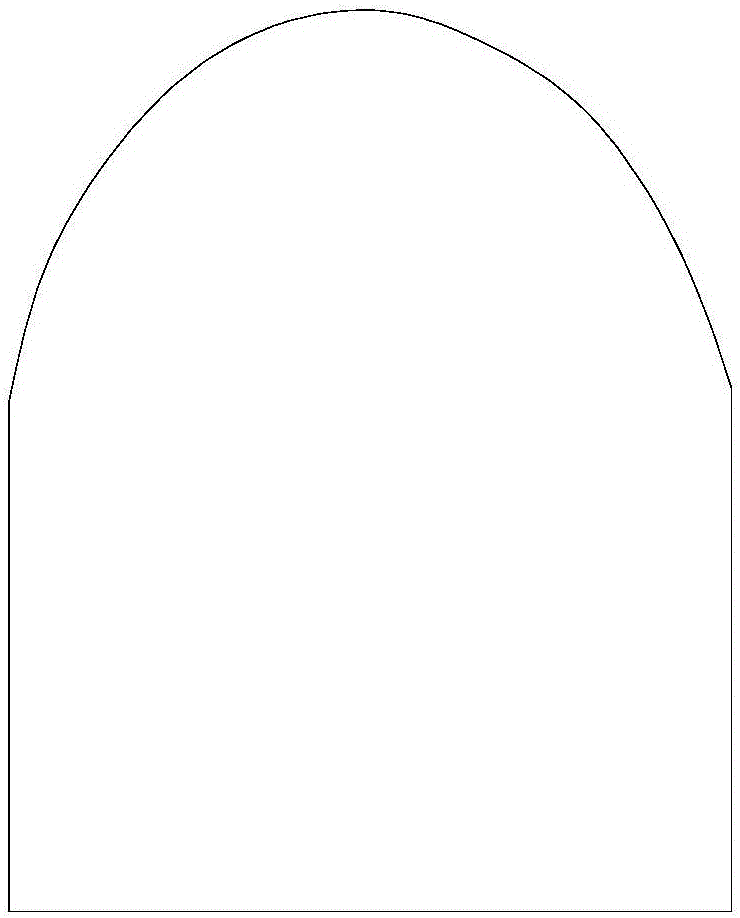

[0016] Step 1. Cut out the outer contour groove with a chainsaw cutter in the horizontal direction along the designed tunnel excavation contour line to form a continuous closed air surface, such as figure 1 shown.

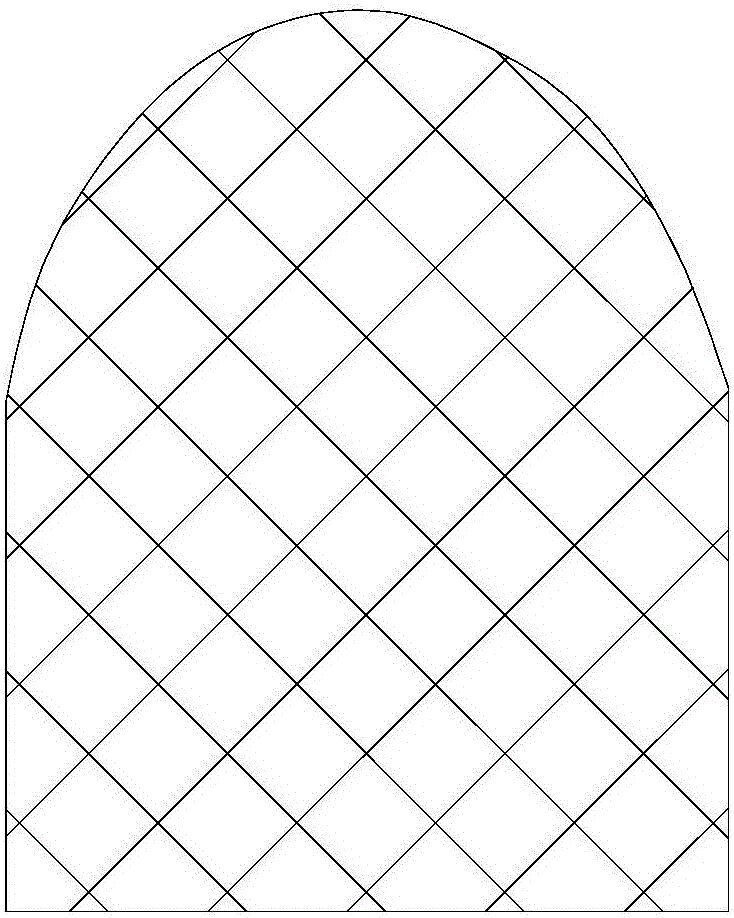

[0017] Step 2. Use the chain saw cutter to cut grooves and divide the tunnel surface in the horizontal direction according to the set track from the excavation contour line inward, and divide the tunnel surface into multiple small pieces, such as figure 2 As shown, it is convenient for the next step of crushing.

[0018] Step 3: Use the crushing head to further crush and remove the split rocks on the face of the face.

[0019] Preferably, in the second step, when the chainsaw cutter cuts the groove, the face is divided into interlaced mesh free surfaces, which has a better crushing effect; it can also be divided into other irregular piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com