Automatic lumbering and pruning robot

A robot and pruning technology, applied in forestry, application, agriculture, etc., can solve the problems of low efficiency, low safety and high risk, and achieve the effect of reducing labor intensity, improving work efficiency and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

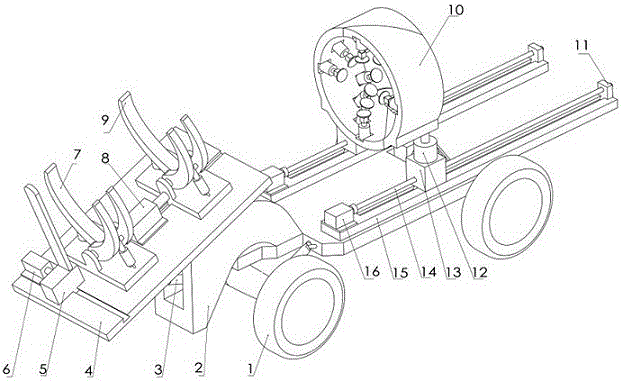

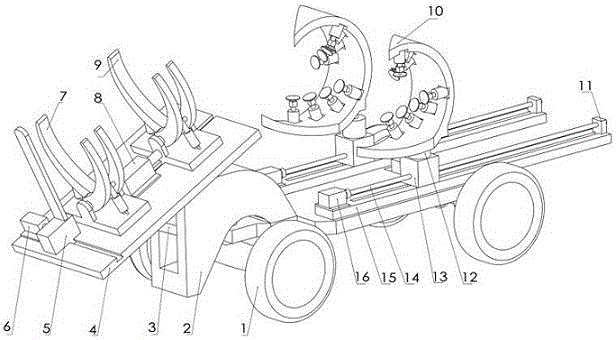

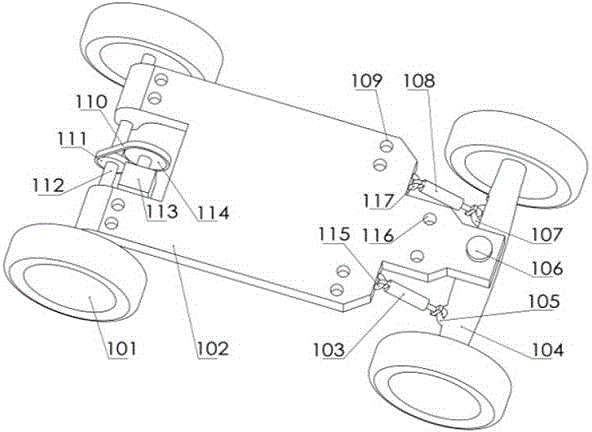

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 As shown, an automatic logging and pruning robot includes: a walking device 1, a support arm 2, a first hydraulic cylinder 3, a support plate 4, a chain saw 5, a first electric cylinder 6, a first gripper 7, a second electric cylinder Cylinder 8, second gripper 9, pruning device 10, two lead screw supports 11, two first stepper motors 12, two sliding supports 13, two lead screws 14, two track plates 15, Two second stepping motors 16, characterized in that: the traveling device 1 includes: four wheels 101, a bottom plate 102, a second rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com