Magnetic control sputtering target

A magnetron sputtering and sputtering technology, which is applied in the direction of sputtering plating, ion implantation plating, metal material coating technology, etc., can solve the problems of burning out the electromagnetic coil, failing to meet the magnetic field requirements, and being unstable , to achieve the effect of prolonging the practical life, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

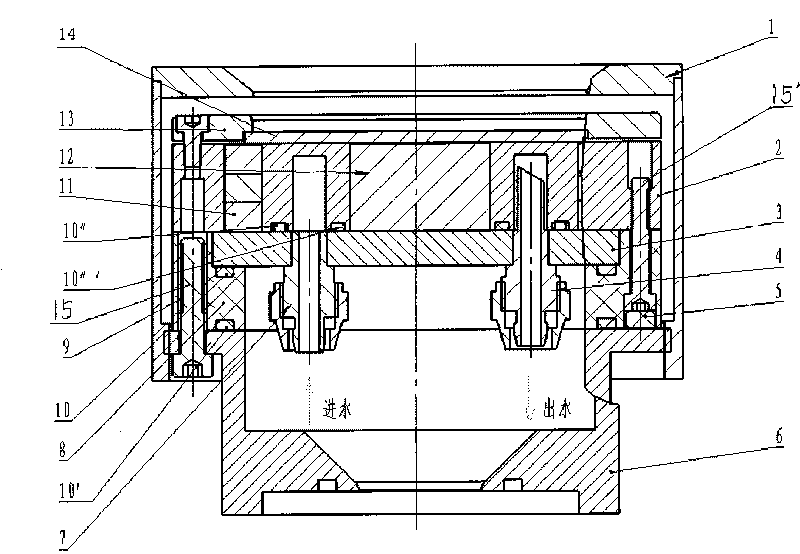

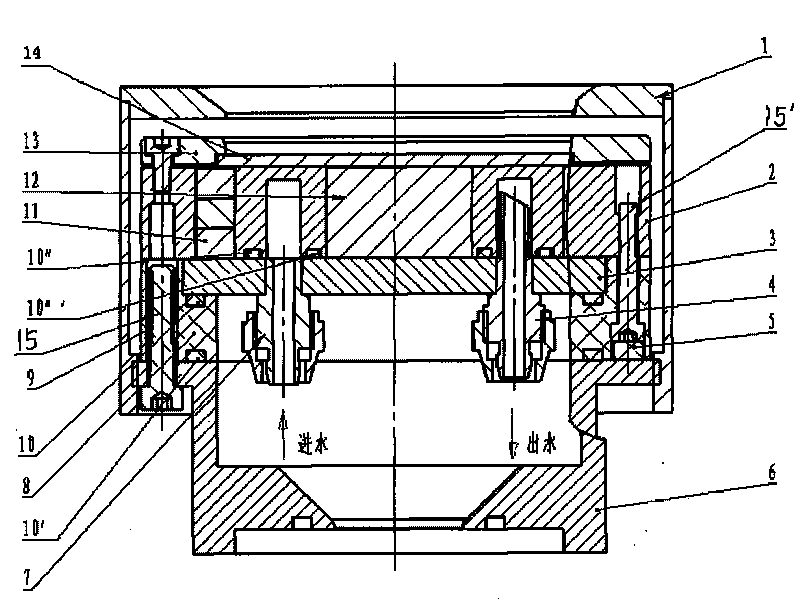

[0016] The structure and principle of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0017] Such as figure 1 As shown, a circular planar magnetron sputtering target of a permanent magnet capable of sputtering magnetic materials, including an outer shield 1, a magnetic steel seat 2, a pole shoe 3, an insulating seat 8, a fixing seat 6, and a target cover 13. Inner magnetic steel 12, outer magnetic steel 11, water inlet nozzle 7, water outlet nozzle 4, connecting bolts and sealing rubber rings 10, 10′, 10″, 10″′; the target material 14 is directly placed on the magnetic steel base 2 , fixed by the target gland 13; the material of the magnetic steel seat 2 is oxygen-free copper, the inner magnetic steel 12 is placed in the center, and a few small holes are drilled around the periphery to place the outer magnetic steel 11, and the polarity of the inner magnetic steel 12 and the outer magnetic steel 11 are opposite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com