High-catalytic-activity anti-carbon-deposition anode material and preparation method thereof

A technology of high catalytic activity and anode material, applied in the field of new anode materials for solid oxide fuel cells and their preparation, can solve the problems of high anode polarization resistance, low battery output power, and high process requirements, and achieve excellent electrochemical performance. , Accelerate the oxidation rate, obvious effect of anti-carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

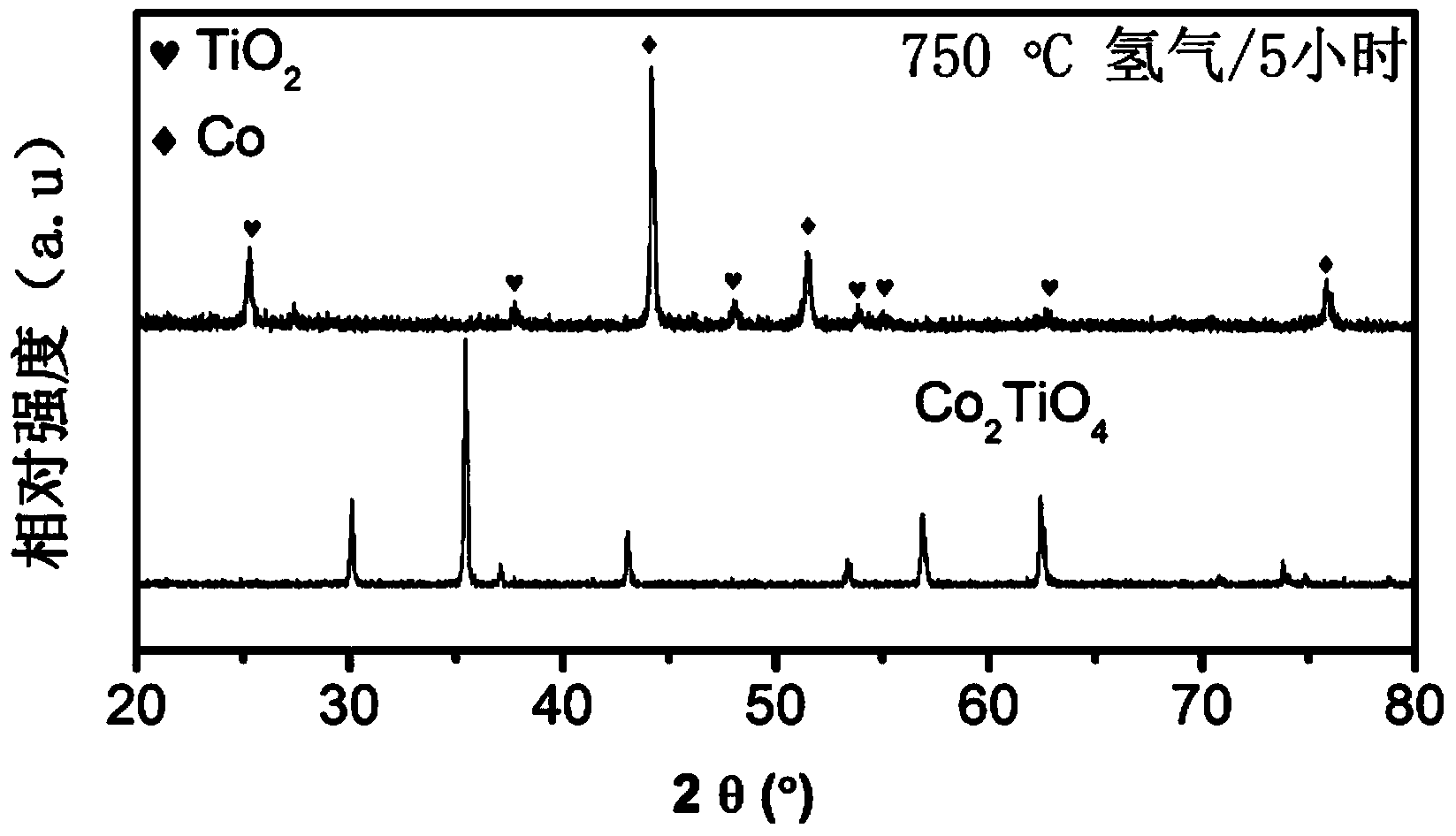

[0046] The present invention has high catalytic activity solid oxide fuel cell anode material Co 2 TiO 4 Preparation and performance test of its corresponding single cell:

[0047] The chemically pure n-butyl titanate (C 16 h 36 o 4 Ti), analytically pure cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) is raw material, dissolves in water by stoichiometric ratio 1:2, adds ethylenediaminetetraacetic acid (EDTA) and citric acid as complexing agent;

[0048] Slowly adjust the solution to a pH value of 7-8 with ammonia water, and stir at an even speed to form a purple clear solution;

[0049] Put the solution in a crucible, heat and concentrate until the solution evaporates to dryness and starts to burn into powder;

[0050] The obtained powder is pre-fired in a muffle furnace at 900°C for 2 hours to remove organic matter, and obtain Co 2 TiO 4 Powder;

[0051] The pre-fired powder is evenly mixed with 20% corn starch and 20% electrolyte powder. As an anode powder, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com