Core-shell structure catalyst for efficient and synergistic removal of NOx and toluene and preparation method thereof

A core-shell catalyst, core-shell structure technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc. problem, to achieve the effect of efficient synergistic removal, prevention of surface carbon, and improvement of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

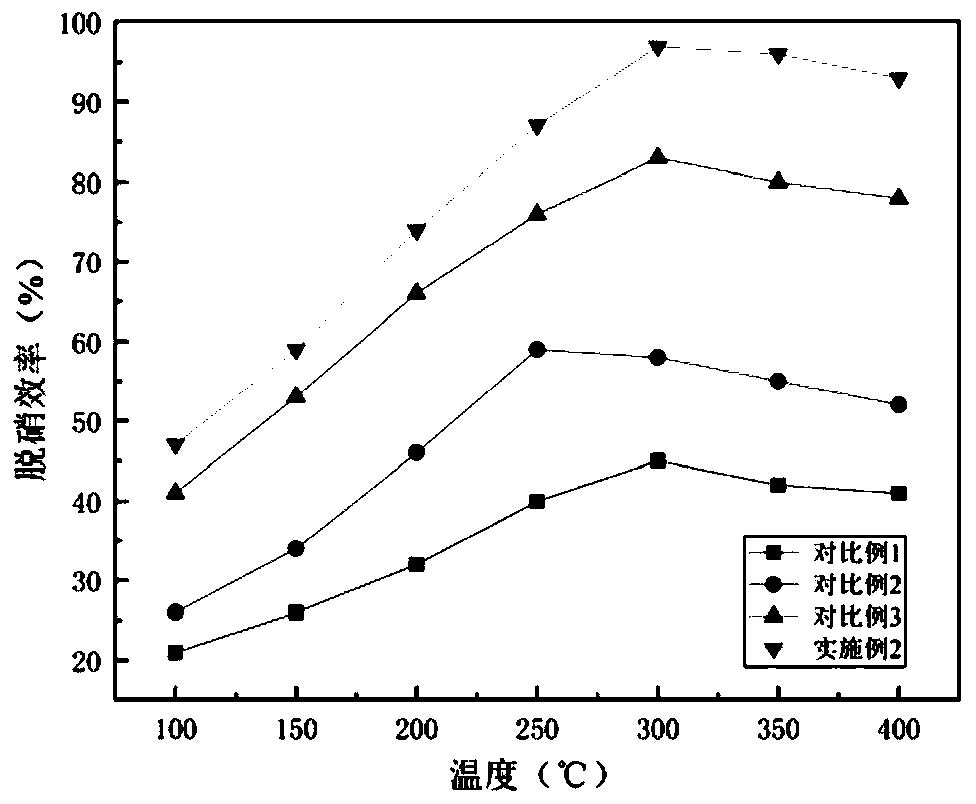

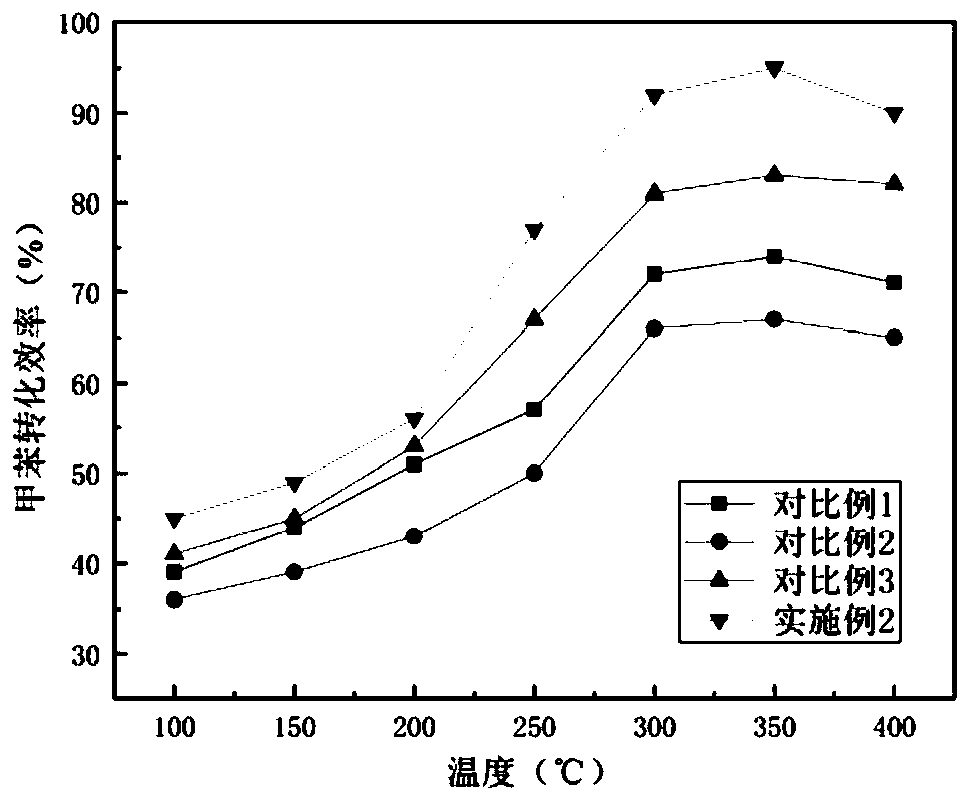

[0027] A pair of NO x Cu / Beta@CeO with efficient synergistic removal with toluene 2 A core-shell catalyst consisting of Cu / Beta as the catalyst core and CeO as the catalyst shell 2 Composition; Beta, Cu, CeO 2 The mass percentages are: 76%, 1%, 23%;

[0028] The precursor of described Cu is copper sulfate; CeO 2 The precursor is cerium nitrate.

[0029] The preparation method of above-mentioned core-shell catalyst comprises the steps:

[0030] (1) Preparation of Cu / Beta core layer: Dissolve 0.3g copper sulfate in deionized water, stir evenly, then stir Beta molecular sieves vigorously at 25°C for 10 minutes to prepare mixed solution 1, and add hydrogen to mixed solution 1 Adjust the pH to 3.0-4.0 with the ammonium oxide solution, filter with suction and wash with deionized water until the pH is 7, and dry at 100°C for 24 hours to obtain the Cu / Beta core layer;

[0031] (2)Cu / Beta@CeO 2 Preparation of core-shell catalyst: Mix ultrapure water and absolute ethanol in equal...

Embodiment 2

[0033] Preparation of the catalyst of the present invention: the preparation conditions and preparation procedures are the same as in Example 1. The difference is that the amount of copper sulfate is 0.45g, so that the mass percentage of Cu is 1.5%. The catalyst can be represented by the following formula, 1.5%Cu / Beta@CeO 2 .

Embodiment 3

[0035] Preparation of the catalyst of the present invention: the preparation conditions and preparation procedures are the same as in Example 1, the difference is that the amount of copper sulfate is 0.6g, so that the Cu mass percentage is 2%, and the described catalyst can be represented by the following formula, 2%Cu / Beta@CeO 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com