Exhaust emission connector of automobile engine and production technology thereof

A technology for automobile engine and exhaust joints, which is applied to engine components, machines/engines, exhaust devices, etc., and can solve problems such as low overall strength, muffler and exhaust manifold failure, crack deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

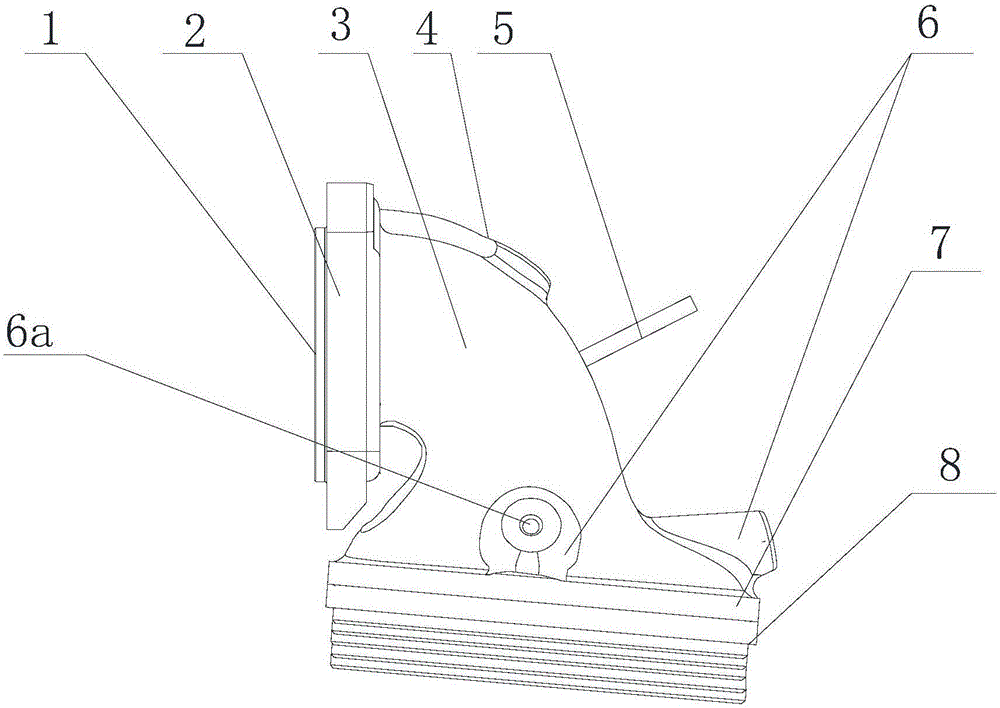

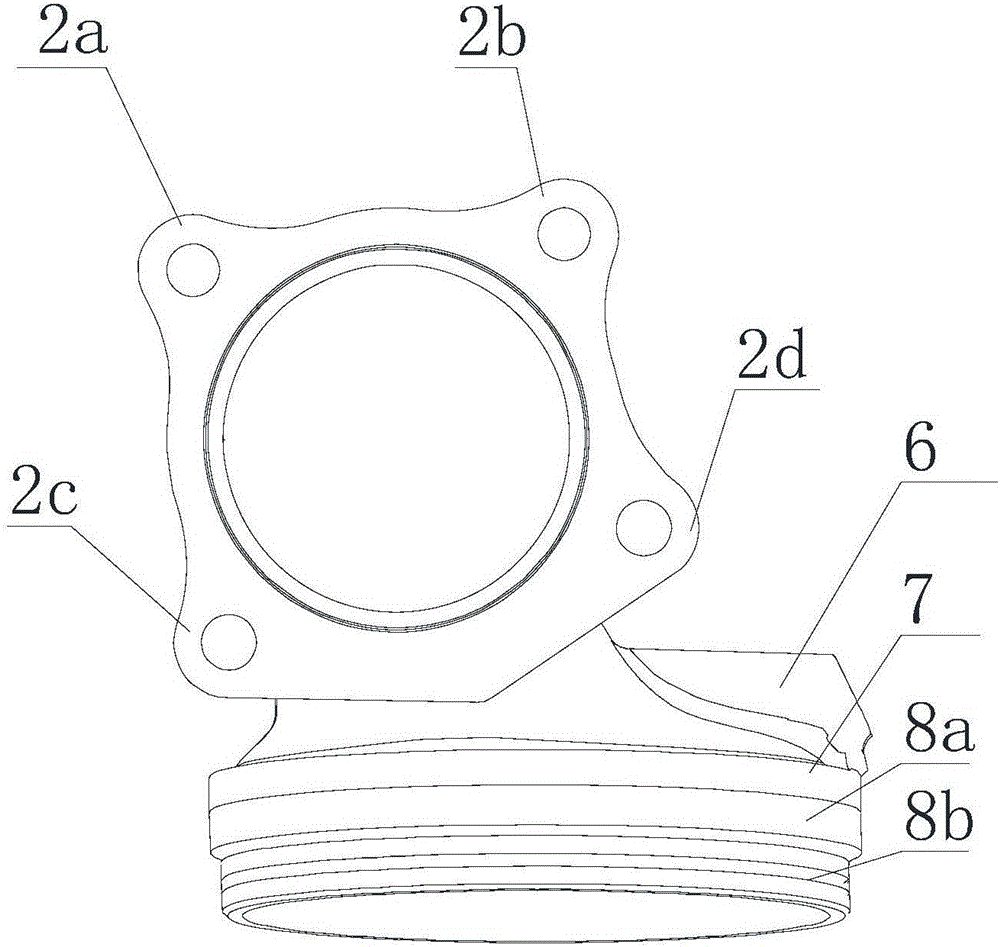

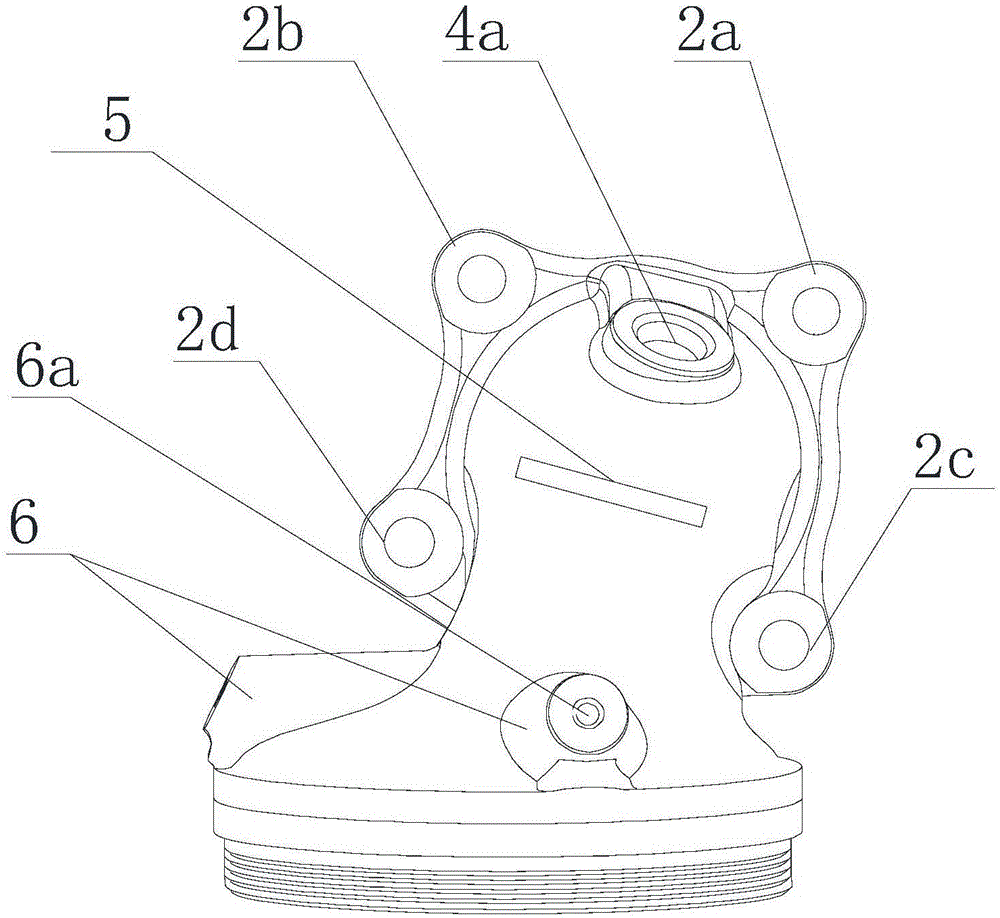

[0077] The automobile engine exhaust joint of the present embodiment, as Figure 1-5 As shown, it includes an elbow 3 and a carbon-removing sound-absorbing device 8. The elbow 3 is provided with an air inlet 1 and an air outlet 7. A heat sink 5 is arranged on the outer wall of the elbow 3. The carbon-removing sound-absorbing device 8 is connected with the outlet. The air port 7 is connected, and a sealing gasket 9 is provided between the carbon removal and sound absorption device 8 and the air outlet 7; the air inlet 1 is provided with a connecting flange 2, and the connecting flange 2 is surrounded by a first connecting part 2a and a second connecting part 2b, the third connecting portion 2c and the fourth connecting portion 2d. The elbow 3 is formed with two first circular positioning bosses 6 near the air outlet 7, and the middle of the top of the first circular positioning boss 6 is formed with a first positioning groove 6a. The elbow 3 is formed with a second circular po...

Embodiment 2

[0122] The automobile engine exhaust joint of the present embodiment, as Figure 1-5 As shown, it includes an elbow 3 and a carbon-removing sound-absorbing device 8. The elbow 3 is provided with an air inlet 1 and an air outlet 7. A heat sink 5 is arranged on the outer wall of the elbow 3. The carbon-removing sound-absorbing device 8 is connected with the outlet. The air port 7 is connected, and a sealing gasket 9 is provided between the carbon removal and sound absorption device 8 and the air outlet 7; the air inlet 1 is provided with a connecting flange 2, and the connecting flange 2 is surrounded by a first connecting part 2a and a second connecting part 2b, the third connecting portion 2c and the fourth connecting portion 2d. The elbow 3 is formed with two first circular positioning bosses 6 near the air outlet 7, and the middle of the top of the first circular positioning boss 6 is formed with a first positioning groove 6a. The elbow 3 is formed with a second circular po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com