Preparation method for dehydrogenation catalyst

A dehydrogenation catalyst, inorganic oxide technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of aggregation and growth of active component Pt particles, Pt sintering and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

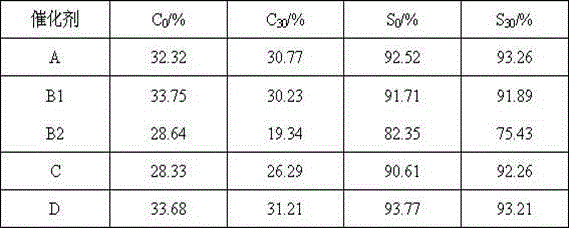

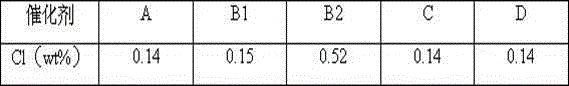

Examples

Embodiment 1

[0025]Preparation of Sn-containing alumina carrier: mix a certain amount of 0.98M aluminum trichloride solution and 0.01M / L tin tetrachloride solution, add a certain amount of 8% ammonia water, and neutralize at 60~80°C Mix evenly in the tank, control the pH value of 7.0~9.0, filter, wash with water, and acidify, pressurize the oil ammonia column to form balls, dry, age, and roast at 650~750°C for 4 hours to obtain granules with a particle size of 1.5mm Spherical alumina containing 0.3wt% Sn.

[0026] Preparation of impregnation solution: Weigh 0.55g of solid chloroplatinic acid and 0.7g of potassium nitrate, dissolve in 100ml of deionized water, and stir thoroughly. Add nitric acid solution dropwise to adjust the pH value of the soaking solution to 1.

[0027] Measure 50ml of spherical alumina carrier containing 0.3wt% Sn and weigh its mass to be about 26g. It was placed in a rotary evaporator and vacuumed for 30 min. Then the impregnating solution was sucked into the rota...

Embodiment 2

[0037] Preparation of impregnation solution: Weigh 0.2 g of solid chloroplatinic acid and 0.62 g of potassium nitrate, dissolve them in 140 ml of deionized water, and stir thoroughly. Add nitric acid solution dropwise to adjust the pH value of the soaking solution to 1.

[0038] Spherical silicon oxide with a diameter of 1.8mm was selected as the carrier. Measure 53ml of spherical silica carrier and claim its mass is about 21g. It was placed in a rotary evaporator and vacuumed for 45 min. Then the impregnating solution was sucked into the rotary evaporator, the vacuum pump was turned off, the temperature of the water bath was kept at 70° C., and the impregnation was carried out at normal pressure for 5 hours.

[0039] Then, the temperature of the water bath was raised to 80°C, the catalyst was vacuum-dried and then transferred into a beaker and placed in an oven at 80°C. Perform temperature-programmed drying in an oven, raise the temperature to 110°C at a rate of 0.5°C / min,...

Embodiment 3

[0043] Spherical zirconia with a diameter of 1.6mm is selected as the carrier. Immerse in an aqueous solution containing cerium nitrate and copper nitrate for 3 hours, dry at 110°C for 2 hours, and bake at 500°C for 4 hours.

[0044] Preparation of impregnation solution: Weigh 1.1 g of solid chloroplatinic acid and 1.4 g of potassium nitrate, dissolve them in 120 ml of deionized water, and stir thoroughly. Add nitric acid solution dropwise to adjust the pH value of the soaking solution to 1.

[0045] Measure 50ml of the spherical zirconia carrier loaded with auxiliary agent and weigh its mass as about 34g. It was placed in a rotary evaporator and vacuumed for 60 min. Then the impregnating solution was sucked into the rotary evaporator, the vacuum pump was turned off, the temperature of the water bath was kept at 70° C., and the impregnation was carried out at normal pressure for 5 hours.

[0046] Then, the temperature of the water bath was raised to 80°C, the catalyst was v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com