Close-range collision type double-fuel engine nozzle component

A dual-fuel engine, close-range technology, used in engine components, machines/engines, fuel injection devices, etc., to solve problems such as high local fuel concentration and adverse soot emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

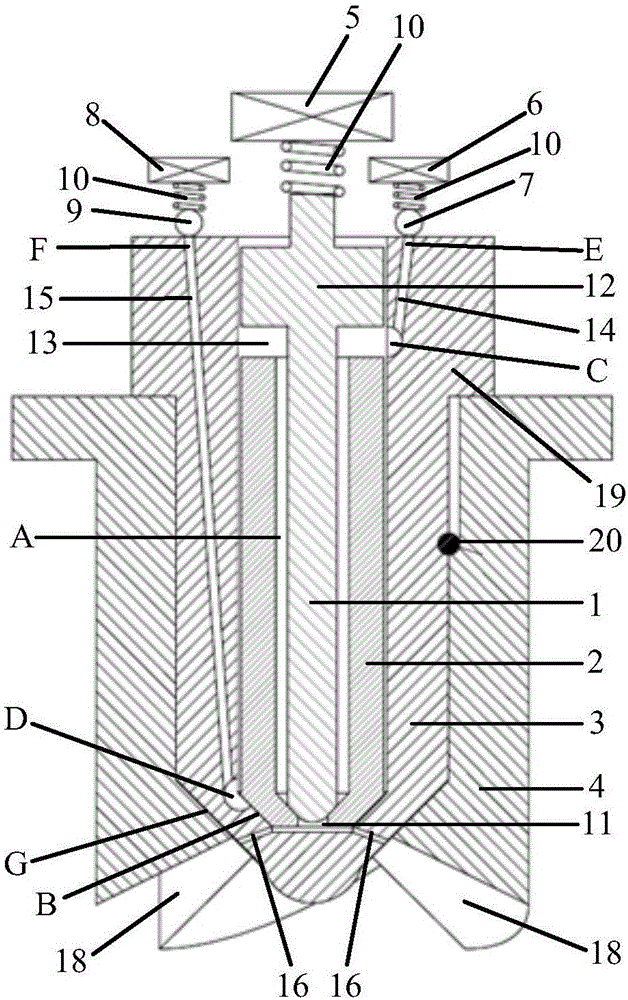

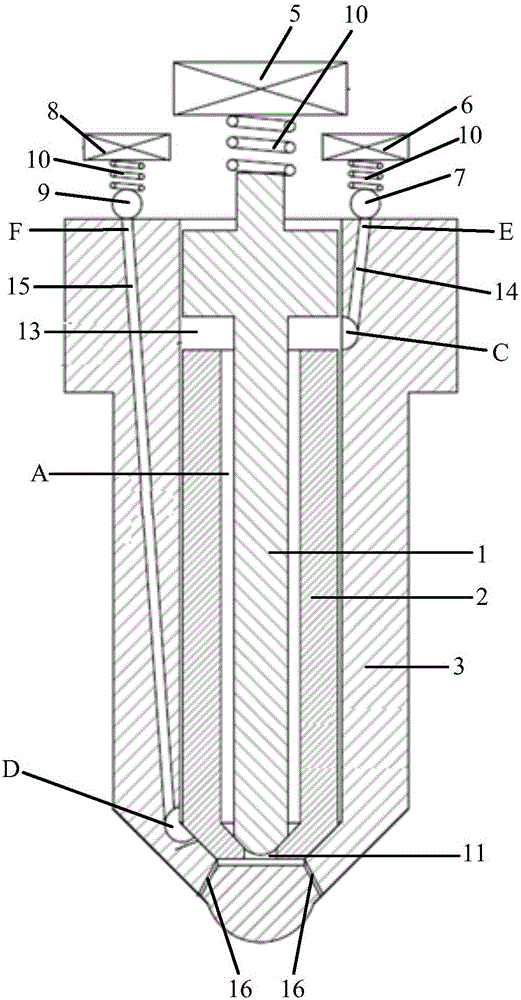

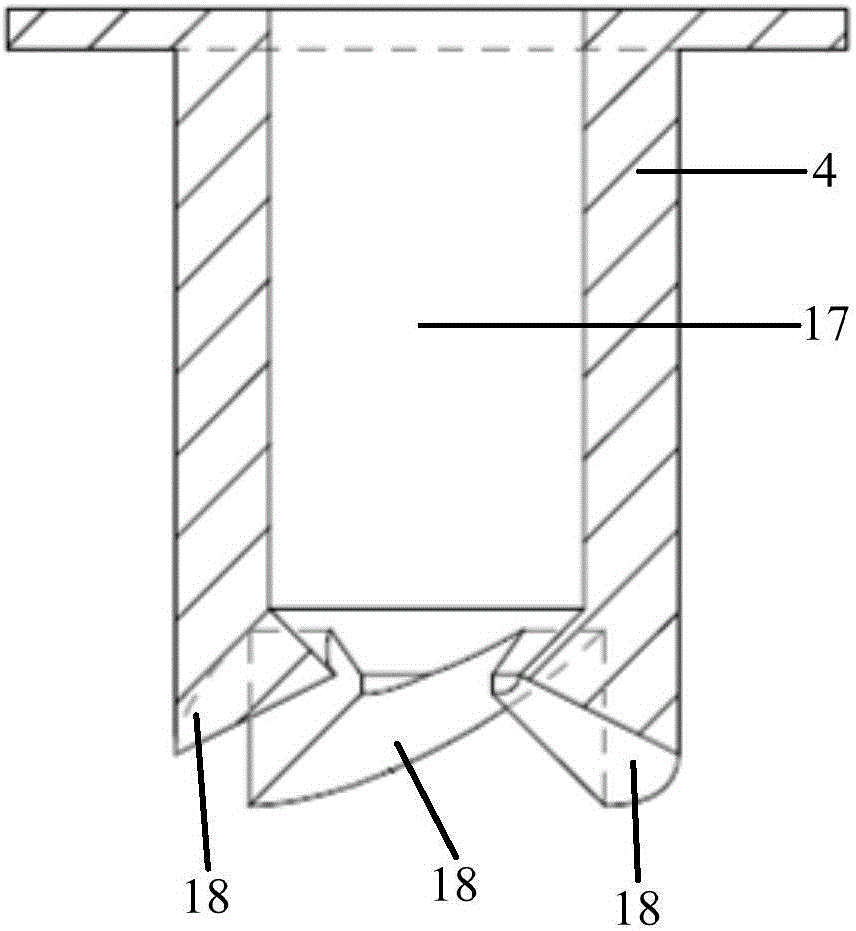

[0025] In order to solve the problem in the prior art that oil film and carbon deposits are formed on the surface of the solid wall after the fuel oil collides with the solid wall, the local fuel concentration is too high, which is not conducive to improving the emission of soot, such as Figure 1 to Figure 4 As shown, the present invention provides a nozzle assembly of a short-range collision type dual-fuel engine, which includes: a needle valve 1, a sleeve valve 2, a nozzle body 3, a collision sleeve 4, a needle valve solenoid Iron 5, first fuel passage electromagnet 6, first ball valve 7, second fuel passage electromagnet 8, second ball valve 9 and spring 10;

[0026] The sleeve valve 2 is a hollow structure, the needle valve 1 is located in the sleeve valve 2 and an annular space A is formed between the needle valve 1 and the sleeve valve 2, one end of the sleeve valve 2 is provided with a fuel outlet 11, and the end surface of the other end is connected to the needle valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com