Solid oxide fuel cell systems

A high-temperature fuel cell and fuel technology, applied in solid electrolyte fuel cells, fuel cells, fuel cell additives, etc., can solve the problems of reducing battery voltage, inability to use electrochemical power generation, and inefficient power generation load transfer, etc., to avoid carbon dioxide. effect of deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

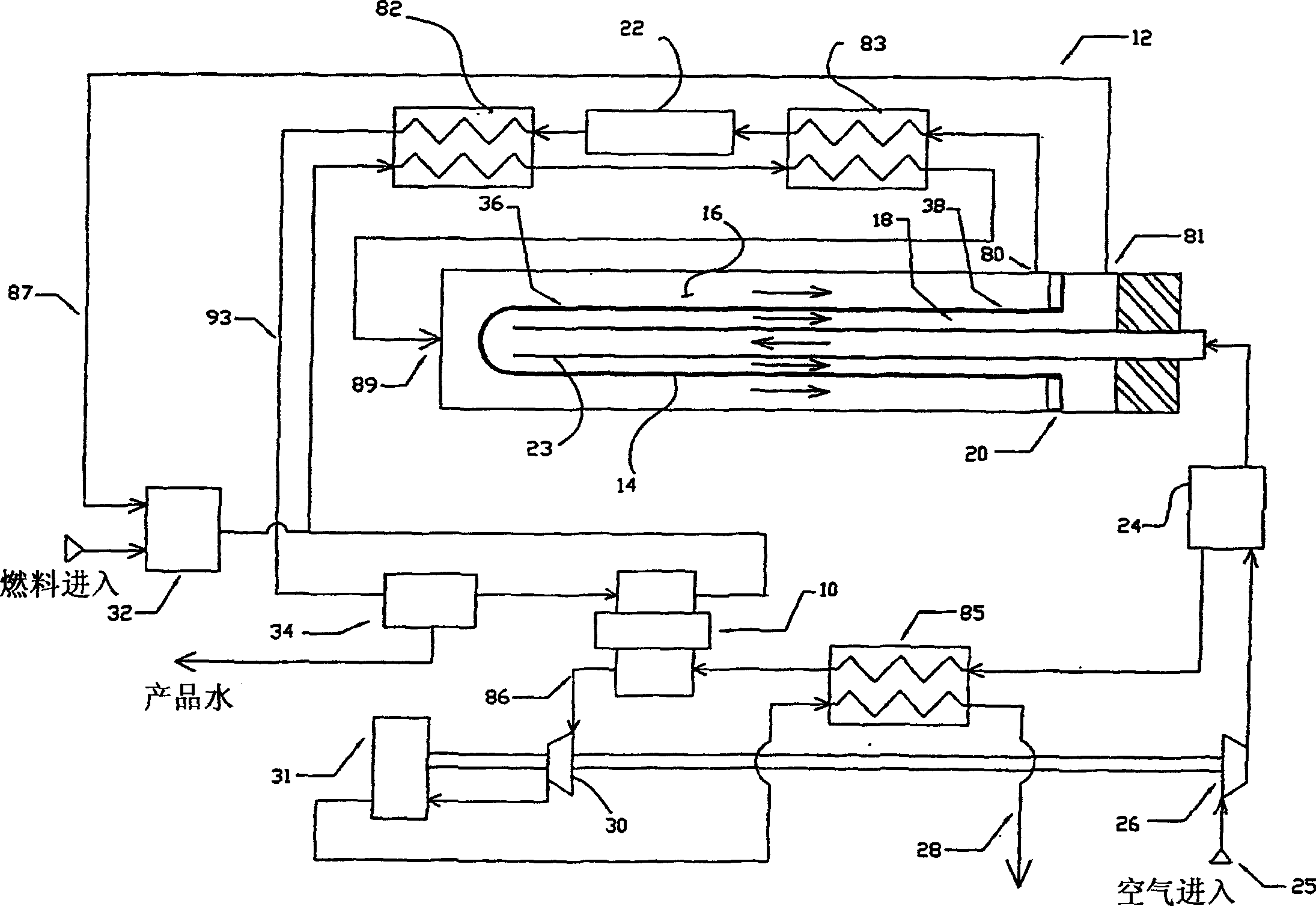

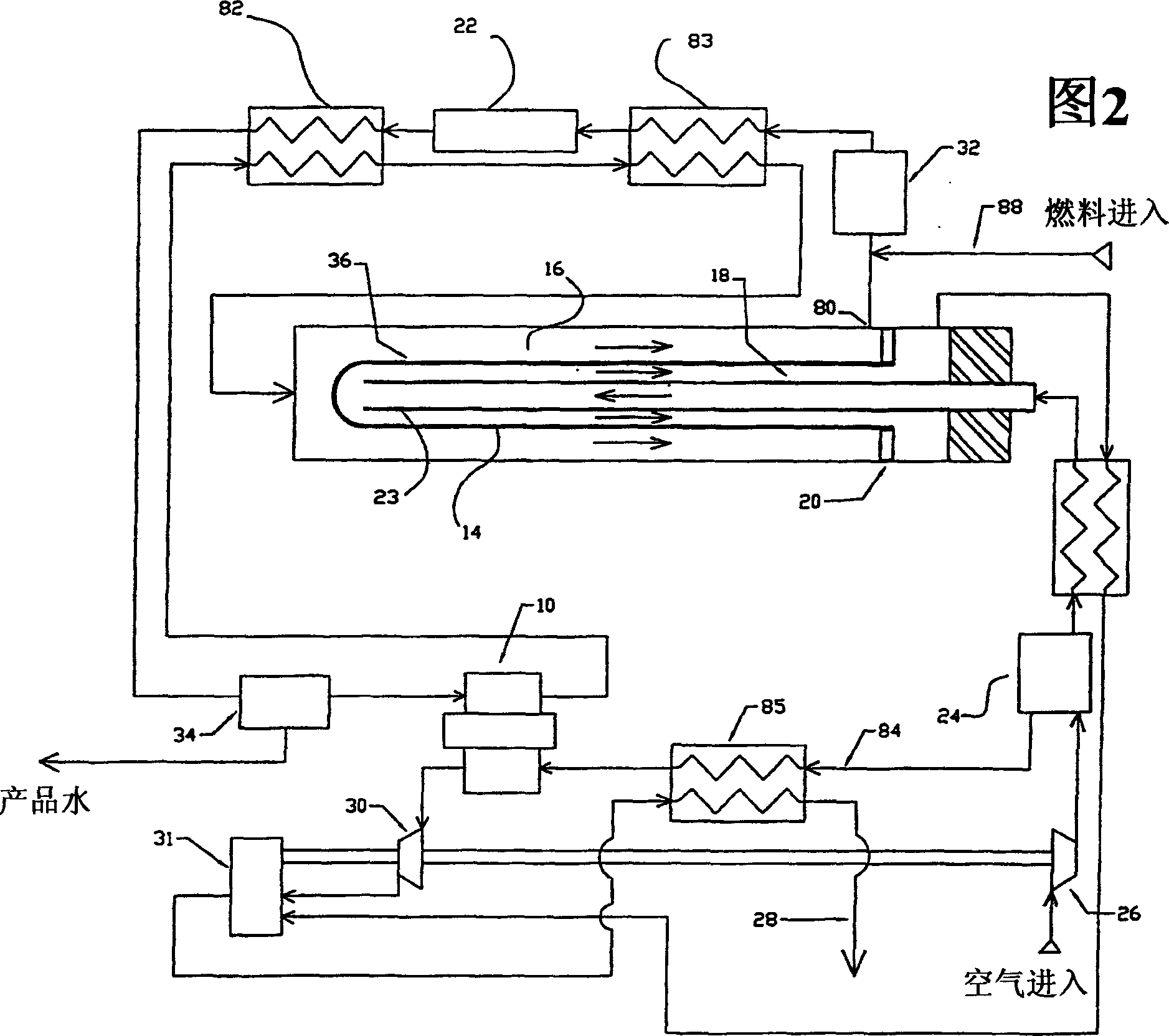

[0048] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT

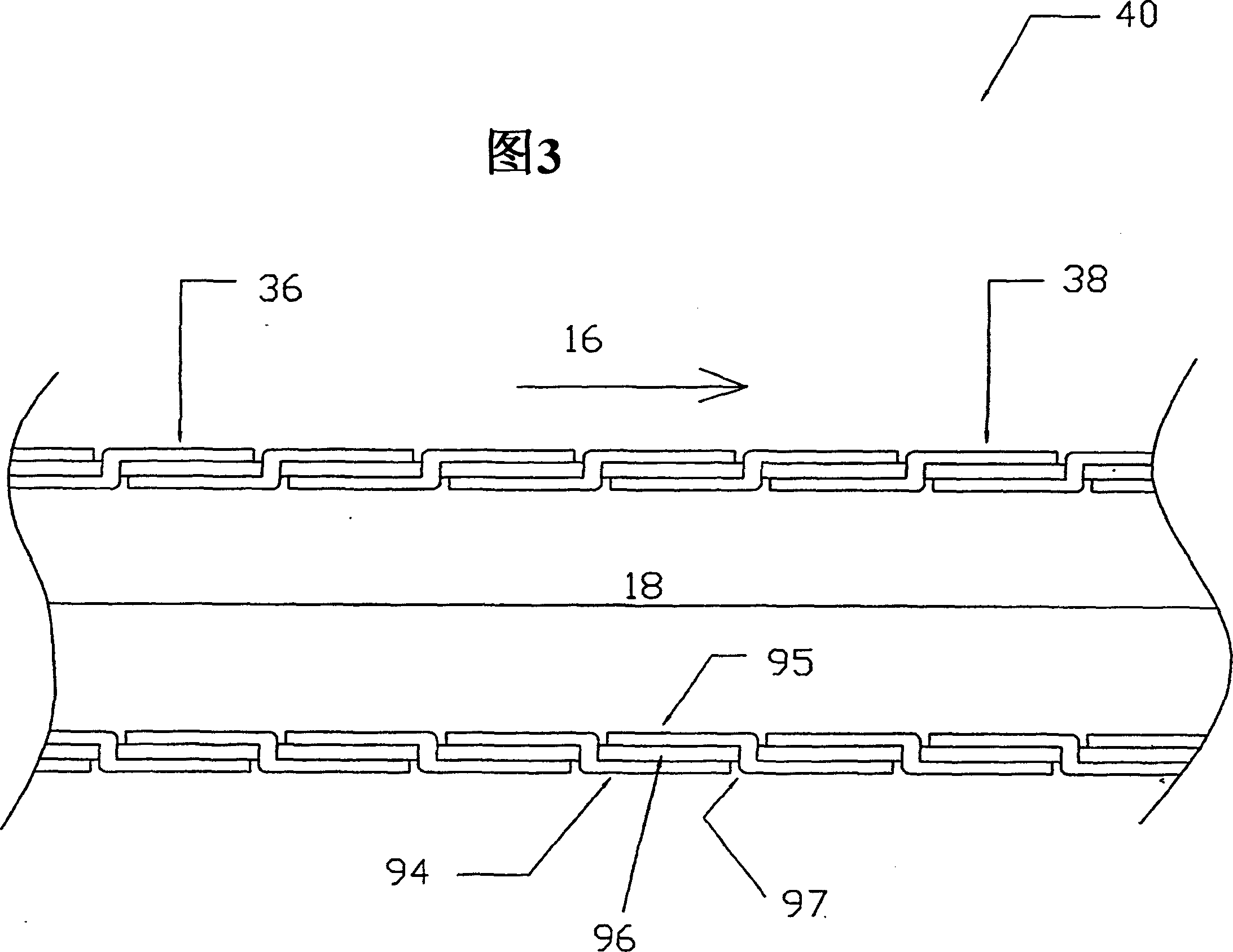

[0049] Combining the hydrogen enrichment spin adsorption module 10 with replacement, cleaning and regeneration functions as the figure 1 - An exemplary gas separation device used in conjunction with the high temperature fuel cell system 12 described in 4 for enriching hydrogen from the anode off-gas and / or concentrating or removing carbon dioxide from the anode off-gas. As used herein, "rotating adsorption module" 10 includes, but is not limited to, devices in which a row of adsorbers rotate relative to a fixed valve face or stator, or devices in which a rotating valve face rotates relative to a fixed row of adsorbers. The illustrated embodiment represents an adsorber mounted on a rotor within a housing of a stator with a fixed valve face. Alternative cycle gas adsorption modules suitable for use in the described embodiments are described in the aforementioned copending patent application 10 / 389,539.

[0050] figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com