Fe-based catalyst, preparation method thereof and application thereof for preparing aromatic hydrocarbons through one-step method by synthesis gas

A catalyst, synthesis gas technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor catalyst stability, low metal dispersion, low aromatics selectivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Weigh 808g of ferric nitrate and dissolve it in 1000g of deionized water, and fully stir at 50°C for 2h to obtain solution I;

[0095] Weigh 100g of aluminum chloride and 50.83g of magnesium chloride and dissolve them in 500g of deionized water respectively, mix them, and fully stir at 50°C for 2 hours to obtain solution II;

[0096] Weigh 544 g of ammonia water (25%), add 100 g of deionized water to the ammonia water, and fully stir at 30° C. for 2 h to obtain solution III.

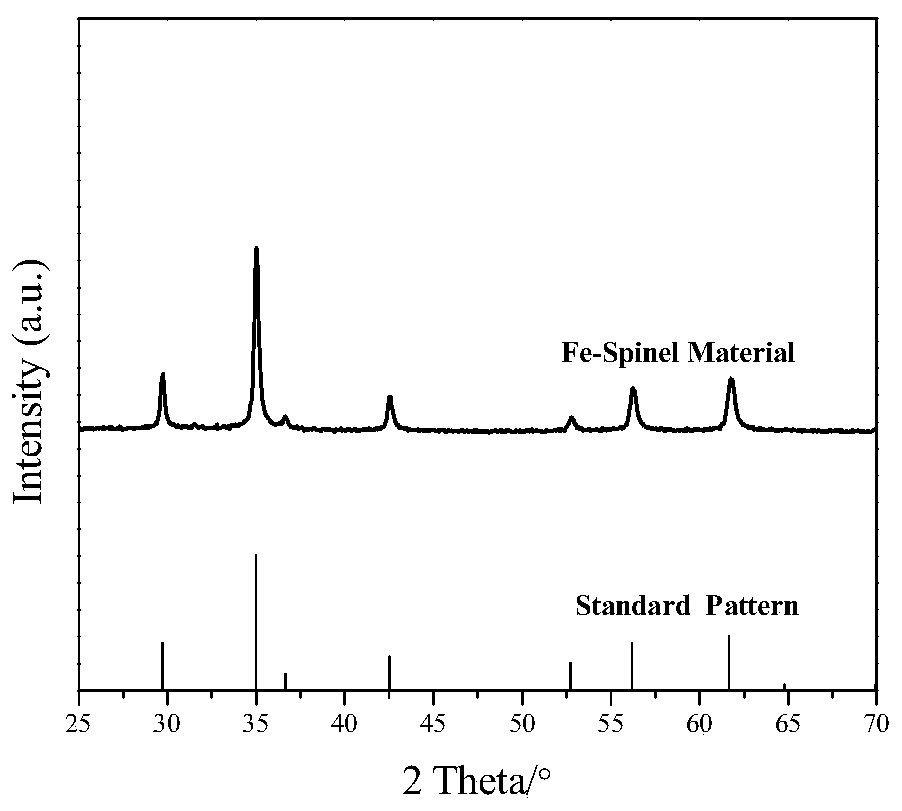

[0097] Slowly add solution I and solution II into the ammonia solution (solution III) sequentially and dropwise under agitation at a temperature of 60°C, then age at 30°C for 6 hours, and finally the solid-liquid mixture is centrifuged to collect the precipitate, After washing to neutrality, dry at 120 °C for 4 h, then transfer to a tube furnace and bake at 800 °C for 12 h to obtain spinel material (Al 0.75 Mg 0.25 Fe 2 o 4 ).

[0098] Weigh 62.1g of calcium nitrate and dissolve it in 100g of...

Embodiment 2

[0105] Adopt the method consistent with embodiment 1 and proportioning to make Fe-2#.

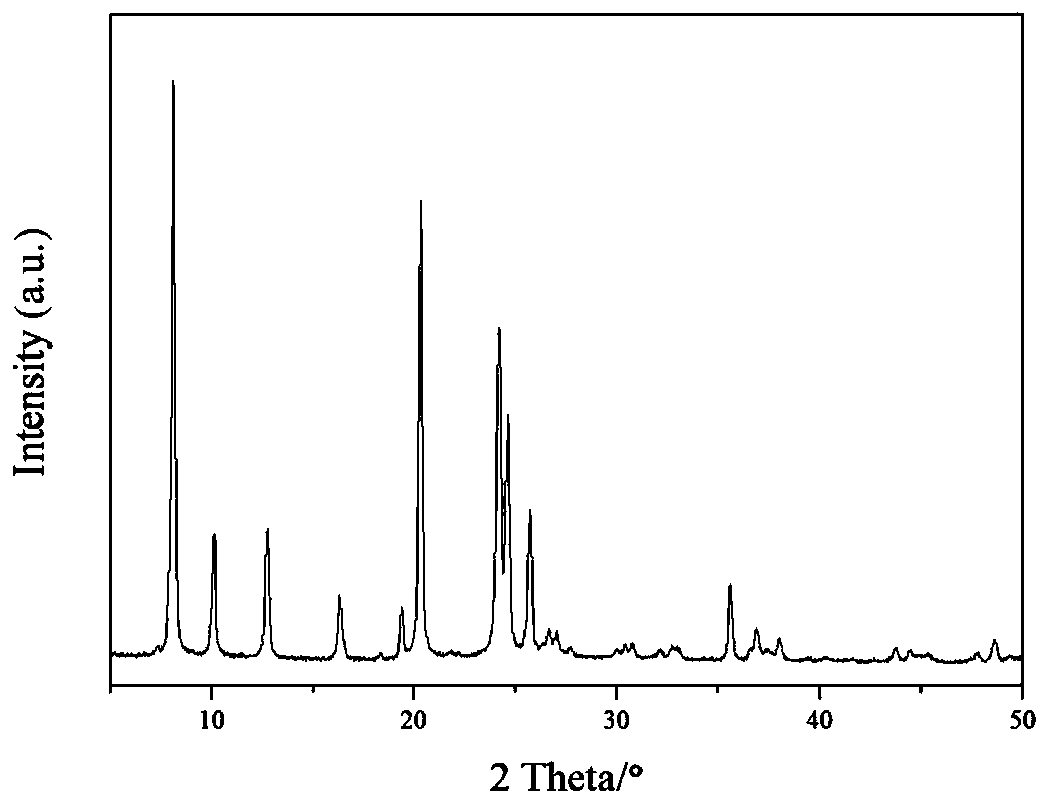

[0106] Weigh 200g of MFI molecular sieve (silicon to aluminum ratio 54), add 3600g of tetraethylammonium hydroxide solution (0.8mol / L), stir at 85°C for 12h, filter and wash, then dry at 70°C for 12h , and finally fired at 500°C for 5h to obtain Z-2#.

[0107] Calculated by mass percentage, 10 g of spinel Fe-2# and 40 g of molecular sieve Z-2# powder were thoroughly mixed and then pressed into tablets to obtain the Fe-based catalyst provided by the present invention.

[0108] Among them, the mass percentages of each component are as follows: Fe-based spinel Al 0.75 Mg 0.25 Fe 2 o 4 : 18.6%, basic modified TON molecular sieve: 80.0%, oxide additive calcium oxide CaO: 1.4%.

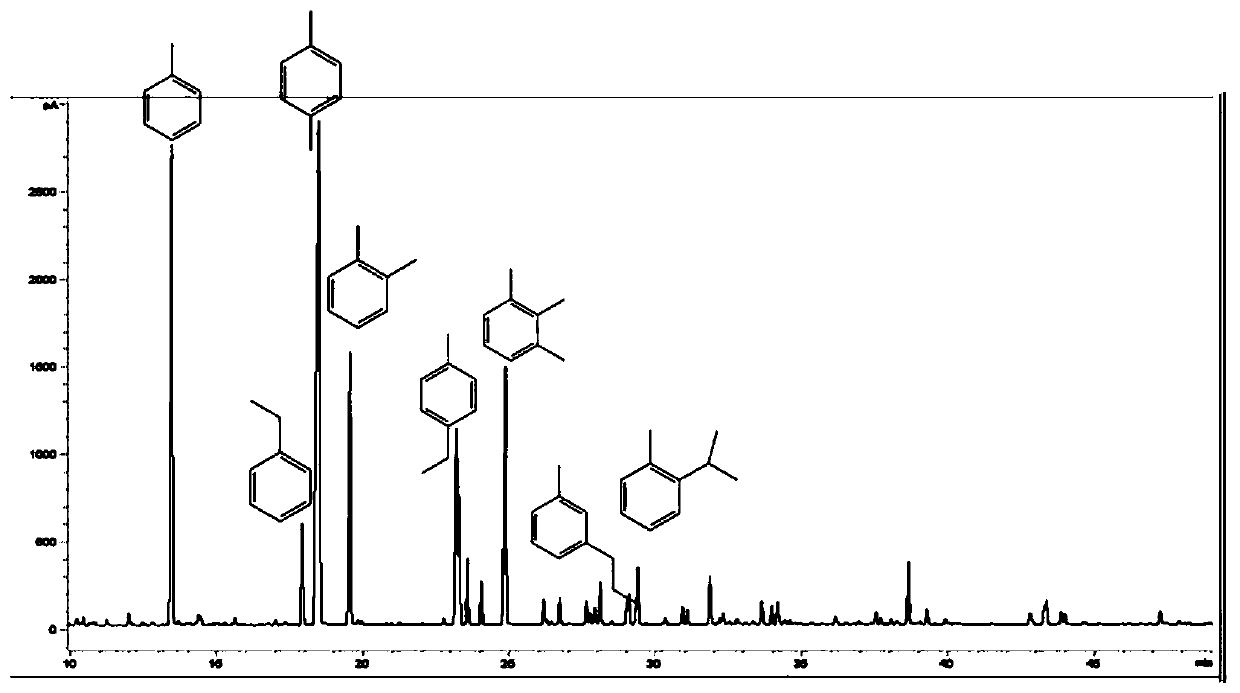

[0109] The reaction condition of catalyst evaluation is: H 2 / CO=1.2, airspeed is 4500h -1 , the reaction temperature is 320°C, the reaction pressure is 0.5MPa, and the reaction results are listed in Table 1.

Embodiment 3

[0111] Weigh 963g of iron acetylacetonate and dissolve it in 1500g of ethanol, and fully stir at 65°C for 1.2h to obtain solution I;

[0112] Weigh 59.5g of zinc nitrate and 174.4g of cobalt acetate and dissolve them in 500g of deionized water respectively, mix them, and fully stir at 40°C for 2.5h to obtain solution II;

[0113] Weigh 256 g of sodium hydroxide, add 400 g of deionized water to the ammonium hydroxide, and fully stir at 45° C. for 1.5 h to obtain solution III.

[0114] Slowly add solution I and solution II to the sodium hydroxide solution (solution III) successively under stirring at a temperature of 75°C, then age at 70°C for 4 hours, and finally the solid-liquid mixture is centrifuged and washed After reaching neutrality, it was dried at 70°C for 24h, and then transferred to a tube furnace for calcination at 750°C for 5h to obtain a spinel material (Co 0.78 Zn 0.22 Fe 2 o 4 ).

[0115] Weigh 10.2g of cerium nitrate and dissolve it in 100g of water to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com