Fuel cell

A fuel cell and stack technology, which is applied in the fields of fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of high production cost, short service life of lithium batteries, inconvenient use, etc., and achieves compact and orderly structure. , Reasonable heat exchange and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

[0028] In the description of the present invention, the terms "first" and "second" are used for descriptive purposes only, and should not be understood as indicating or implying relative importance.

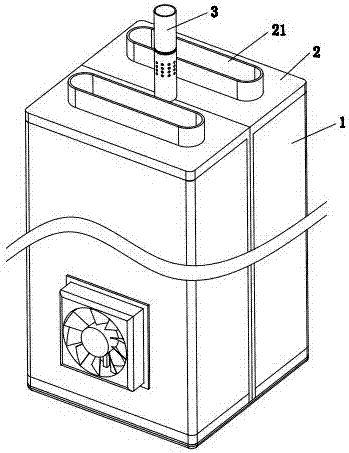

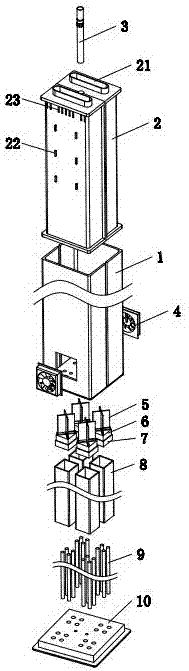

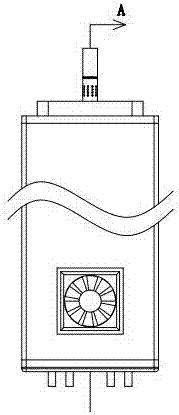

[0029] like Figure 1 to Figure 7 As shown, it is a fuel cell comprising:

[0030] The heat-insulating inner shell 2 and the outer shell 1; the outer shell 1 is set on the heat-insulating inner shell 2, and the inner wall of the outer shell 1 cooperates with the outer wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com