Steam heating pot system

A technology for heating a pot and steam, applied in the direction of a heating device, etc., can solve the problems of large temperature difference in the central part of the pot body, large energy consumption, heat concentration, etc., and achieve the effects of uniform heating temperature, low comprehensive cost, and reasonable heat exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

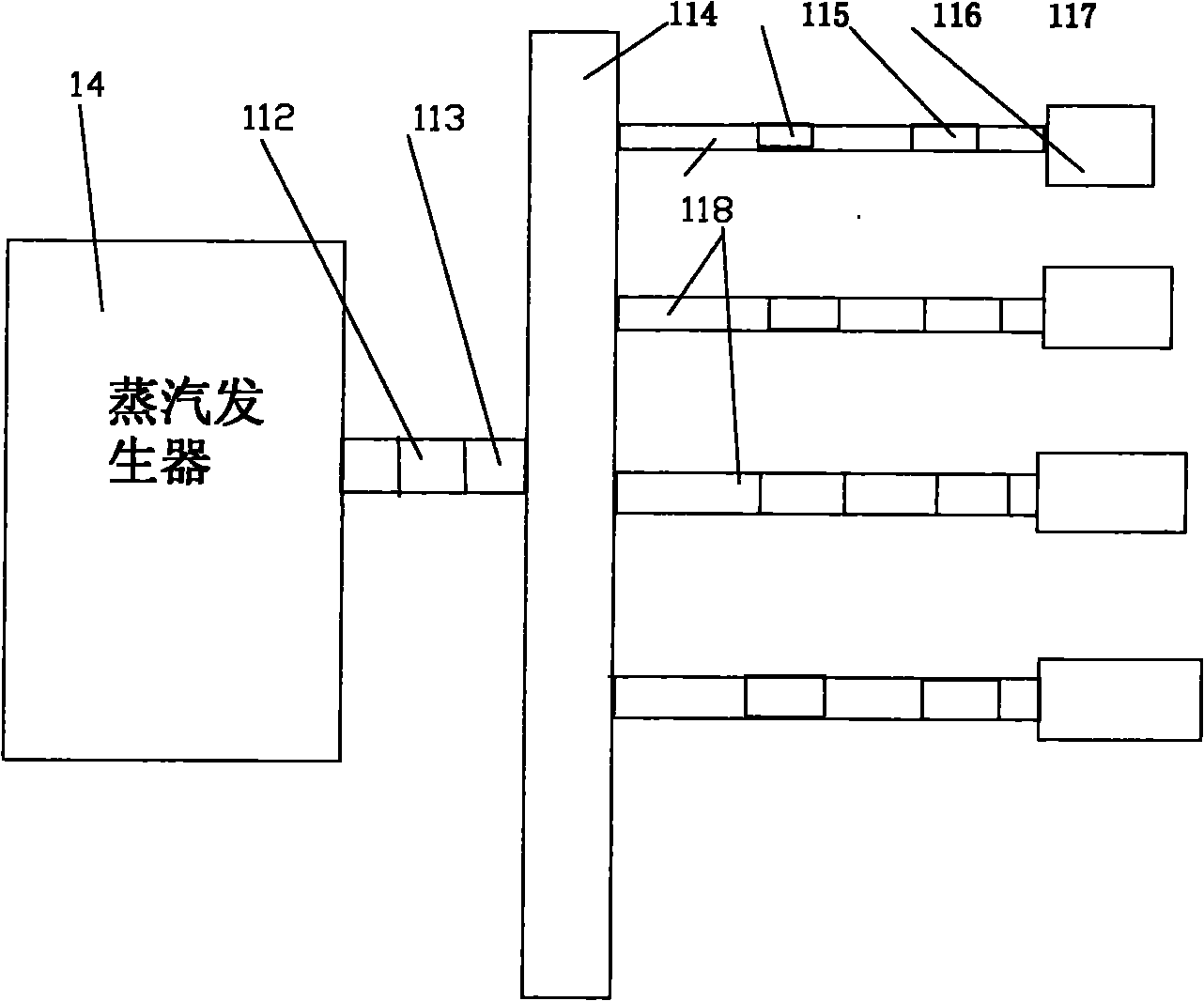

[0018] refer to figure 1 Shown, provide a kind of chafing dish system that adopts steam heating, be provided with a steam generator 14, the output port of described steam generator 14 is equipped with safety valve 112 and main control valve 113, at the outlet of described main control valve 113 Connected with a main pipe 114, the main pipe 114 is connected with a plurality of small branch pipes 118, each small pipe 118 is connected with a small safety valve 115 and a small control valve 116, and the outlet of the small control valve 116 is connected with a steam heating The pot 117 is connected; the main pipeline 114 and the branch small pipeline 118 are covered with an insulating layer.

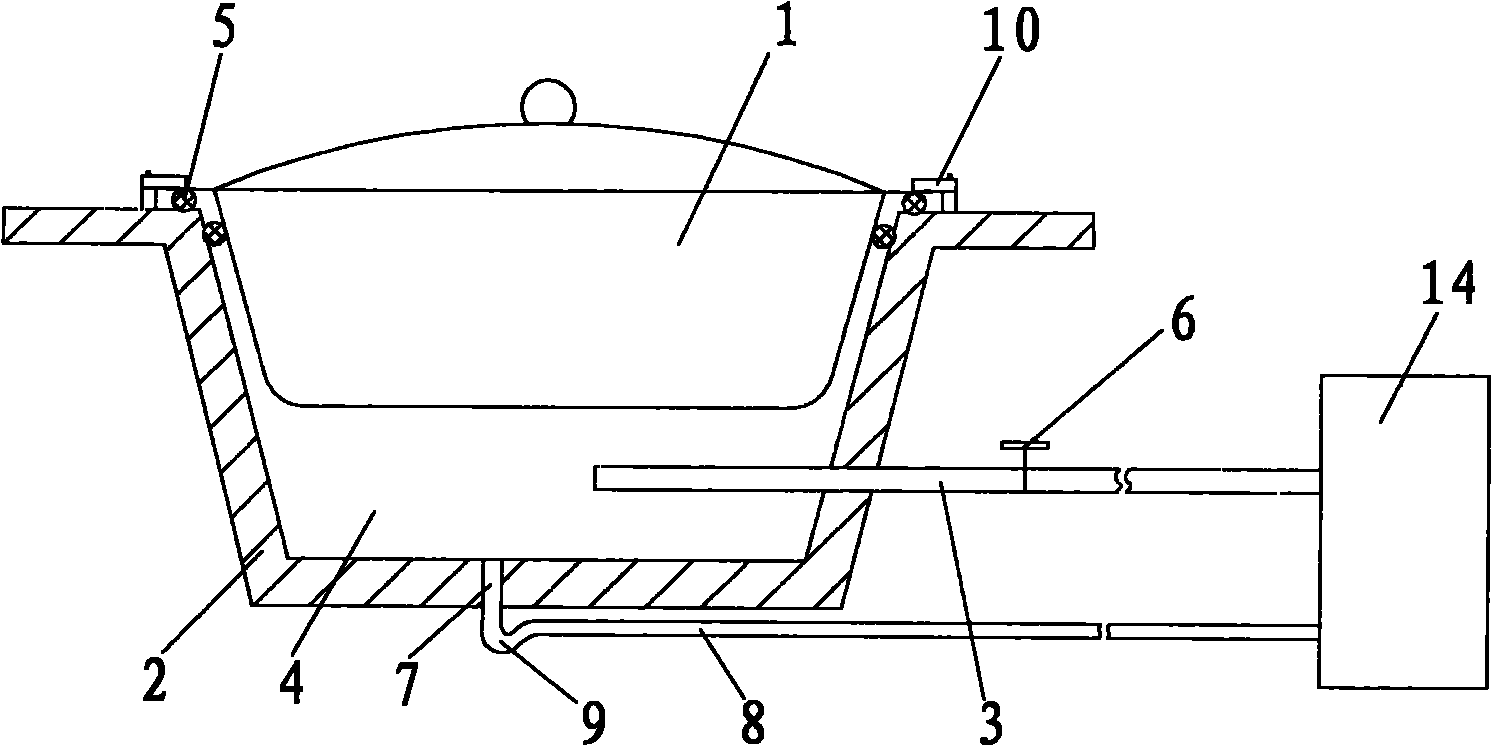

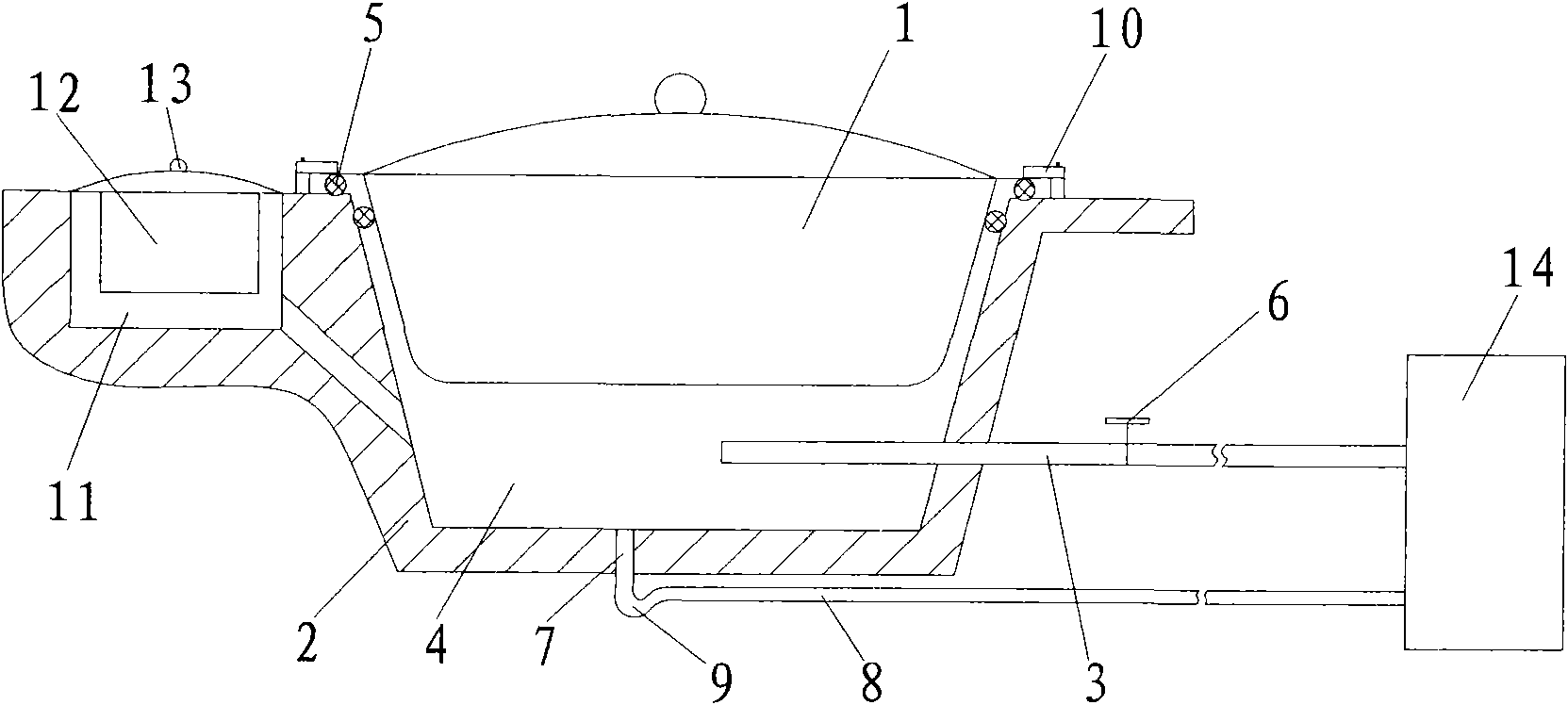

[0019] The structure of the steam heating pot is as follows: figure 2 As shown, a pot body 1, a base 2, and a steam input pipe 3 are provided, and the base 2 is recessed downward to form a groove-shaped steam chamber 4 for placing the pot body 1, and the bottom of the pot body 1 is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com