Circumferential heating type baking needle used for electronic cigarette and electronic cigarette

An electronic cigarette, heating technology, used in ohmic resistance heating parts, electric heating devices, heating elements, etc., can solve problems such as harmful to human health, and the taste of baking is not pure enough to achieve better taste, simple and fast installation, and baking. Even heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

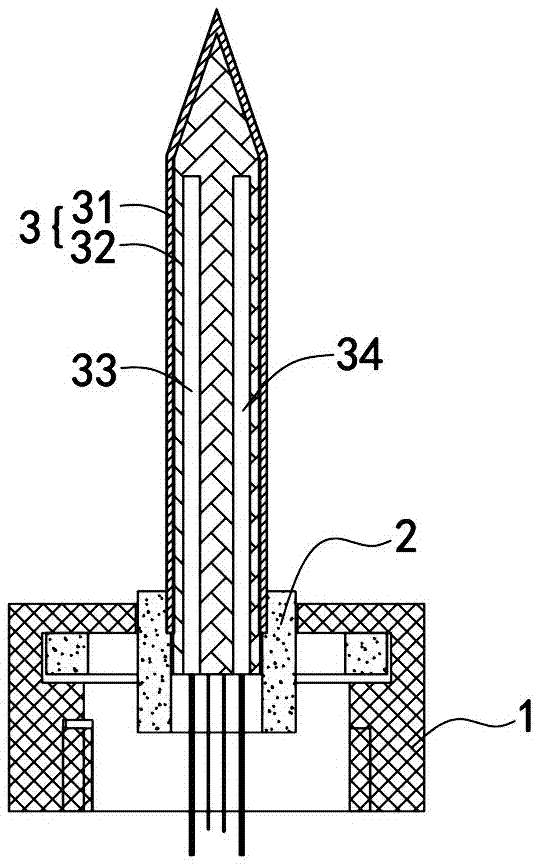

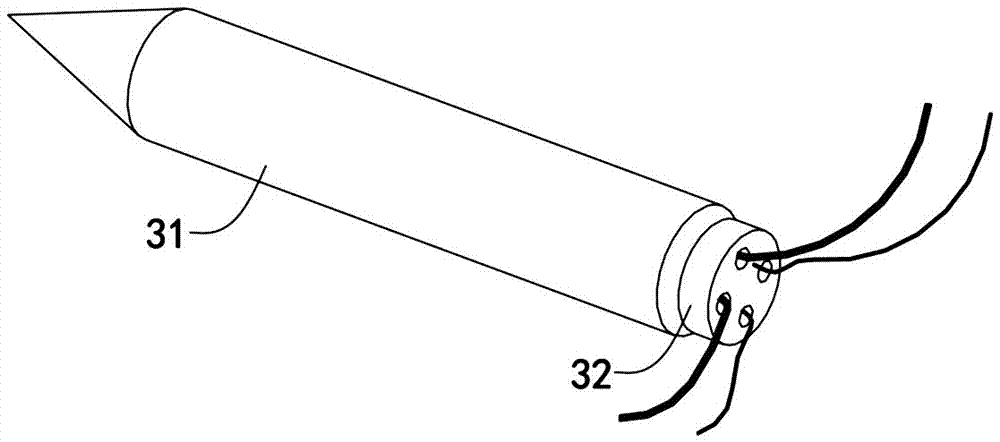

[0028] Such as figure 1 and figure 2 As shown, the circumferential heating type baking needle used for electronic cigarettes in this embodiment includes a baking needle 3 with a built-in heating element, and the outside of the baking needle 3 is coated with a non-stick coating. The circumferential heating type baking needle used in electronic cigarettes in this embodiment realizes circumferential heating through the baking needle 3, which has the advantages of uniform baking heat and simple and quick installation; the outside of the baking needle 3 is coated with a non-stick coating, The non-stick coating can effectively prevent the atomized medium such as tobacco and its baking residue from sticking to the baking heating element during the baking heating process, so as to avoid carbon deposits, tar and nicotine during repeated baking procedures It has the advantages of more mellow taste, lower tar and nicotine in cigarettes, health and sanitation, no carbon deposit in use, ...

Embodiment 2

[0046] In this embodiment, the non-stick coating is Teflon non-stick nano-coating. Compared with ordinary Teflon non-stick coating, Teflon non-stick nano-coating has the advantages of smoother surface, stronger adhesion and more advanced technology, which can further enhance the prevention of tobacco and other mist during baking and heating. The chemical medium and its baking residue will stick to the baking heating element, enhance the efficiency of avoiding carbon deposits and harmful substances such as tar and nicotine during repeated baking procedures, and make cigarettes taste more mellow. It is better to reduce tar and nicotine in cigarettes.

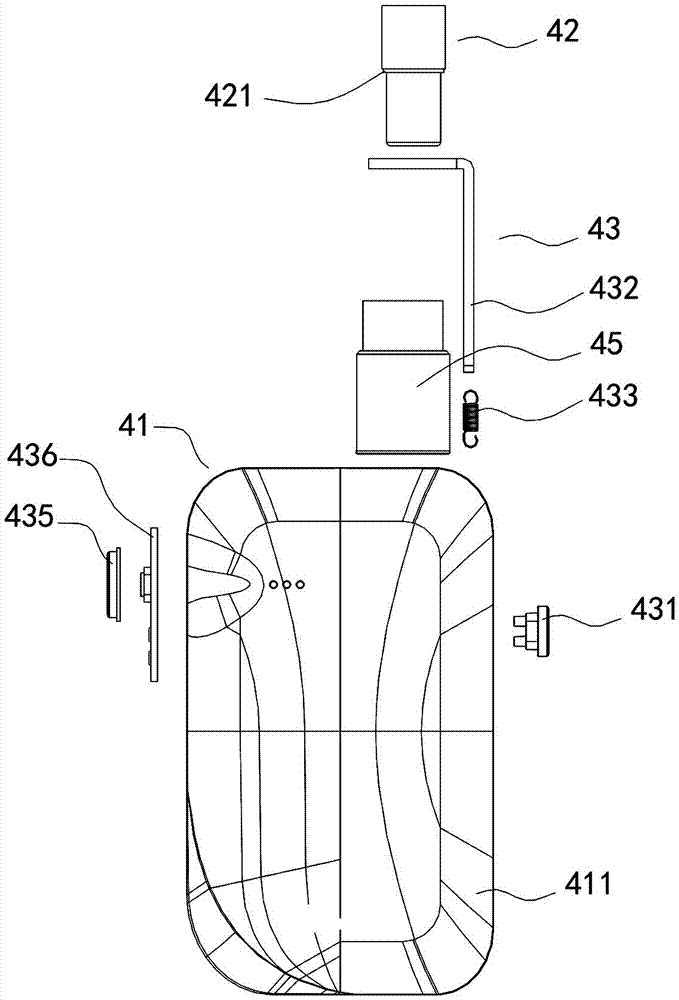

[0047] Such as Figure 5 As shown, the pod of this embodiment includes a tobacco cup 51 , and tobacco shreds are installed in the tobacco cup 51 , and a socket 511 for inserting a heating needle is provided at the bottom of the tobacco cup 51 . Through the above-mentioned structure, the bottom can be supported to insert the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com