Chain belt type areca nut processing machine

A processing machine and betel nut technology, which is applied in the fields of application, food preparation, food science, etc., can solve the problems that the boat-shaped betel nut slices cannot be fixed, and the brine cannot be accurately centered, etc., and achieve the effect of compact structure, small footprint, and expanded output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

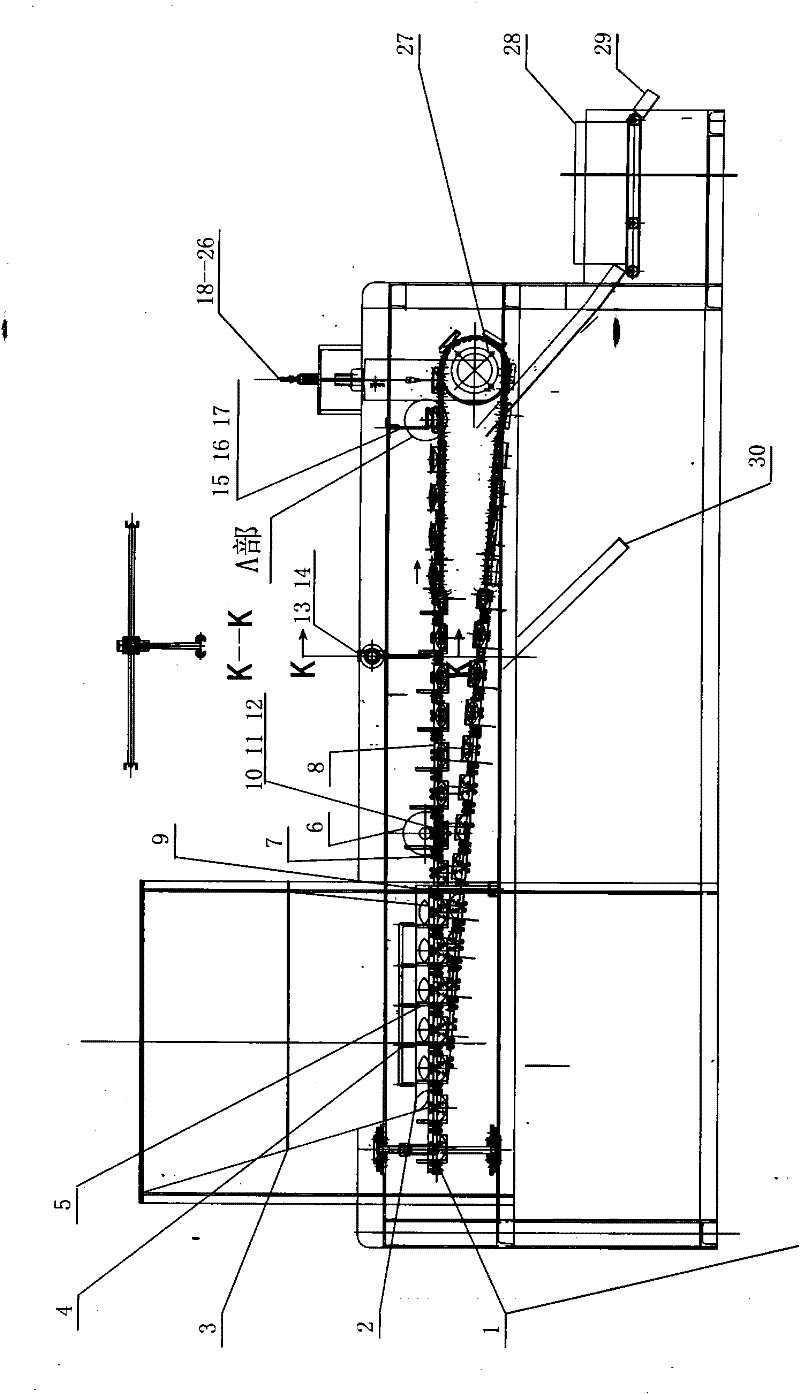

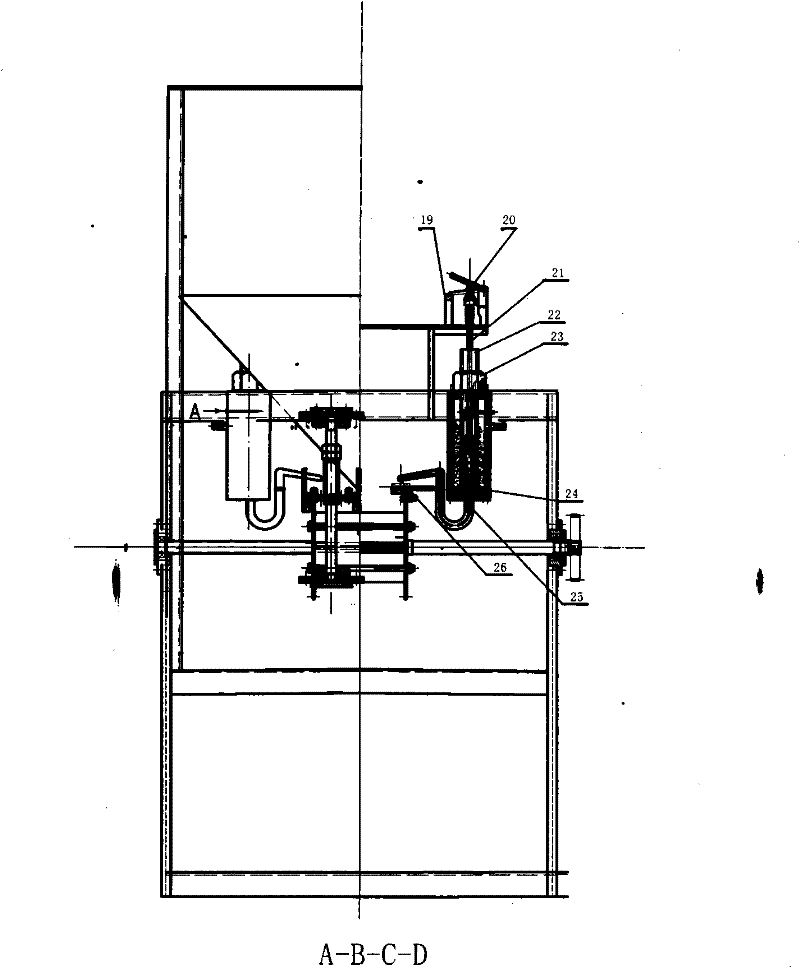

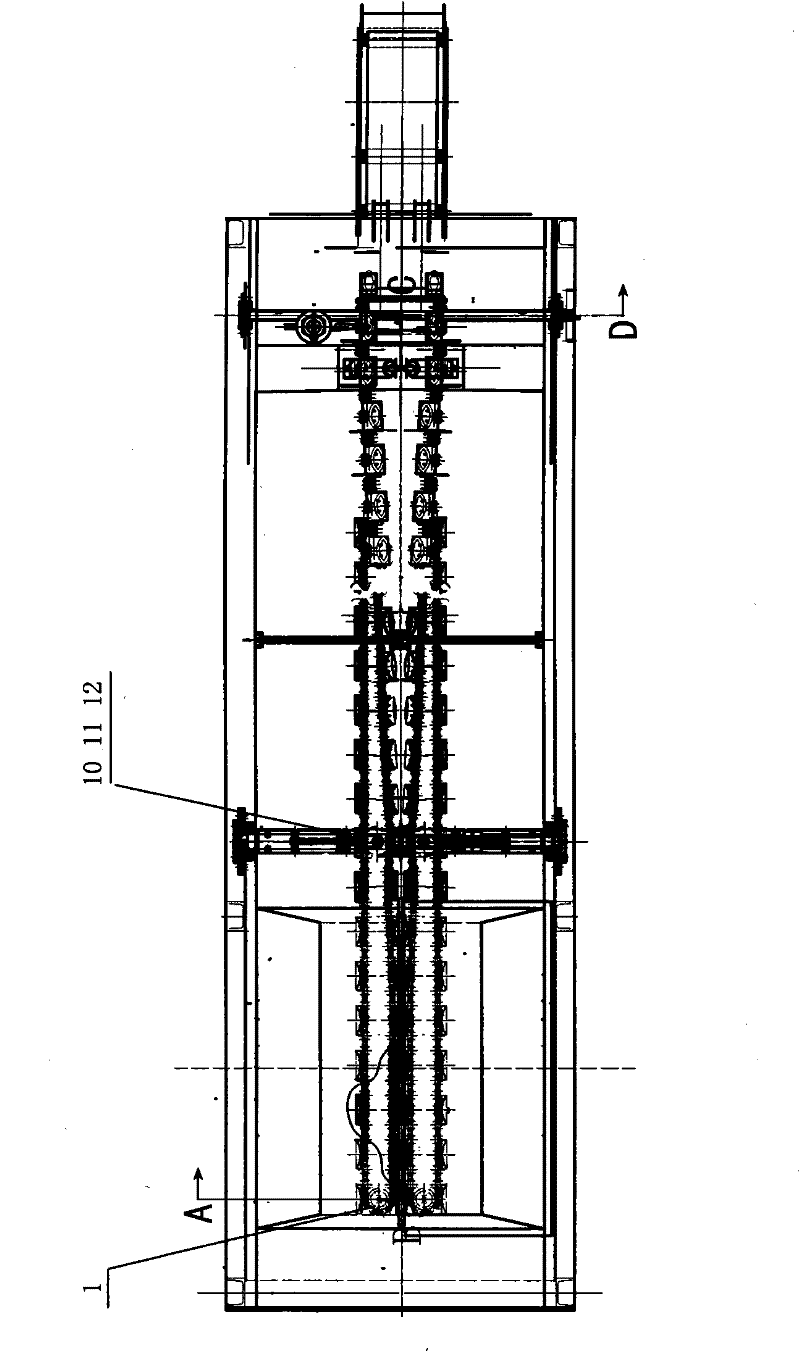

[0039] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 8 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 ,and Figure 18 As shown, this chain-belt type betel nut processing machine consists of a horizontal material receiving sprocket (1), a chute (2), a feeding device (3), a retaining rod (4), a material shifting rod (5), a circular blade (6), Chain belt (7), betel nut claw nest (8), sub-belt bolt (9), betel nut extrusion device (10), extrusion sprocket wheel (11), extrusion rod (12), nuclear removal device (13), Denuclearizing shrapnel (14), point halogen switch device (15), point halogen switch device shrapnel (16), point halogen switch device button (17), point halogen gun (18), point halogen switch suction iron (19), point Brine pressing rod (20), piston rod (21), brine adjusting sleeve (22), brine adjusting nut (23), piston cylinder main body (24), brine outlet joint (25), brine outlet nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com