SiO<x>/C composite cathode material, method for preparing same and application of SiO<x>/C composite cathode material

A negative electrode material, silicon-carbon composite material technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of battery negative electrode or lithium-ion battery capacity attenuation, insufficient cycle performance, low first Coulomb, etc., to achieve Improved Coulombic efficiency and cycle performance, stable structure, and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

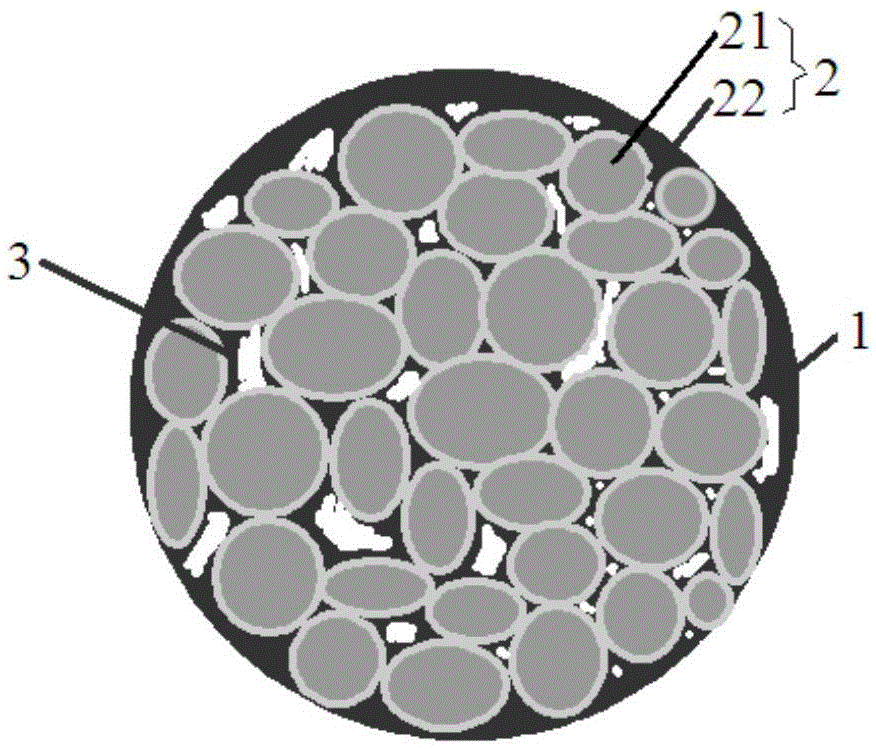

[0037] On the other hand, the embodiment of the present invention also provides the above-mentioned embodiment of the present invention SiO x The preparation method of / C composite negative electrode material. In one embodiment, combined with the figure 1 , the preparation method of the high magnetic permeability wave-absorbing sheet of the embodiment of the present invention comprises the following steps:

[0038] Step S01: On SiO x An amorphous conductive carbon layer 22 is deposited on the surface of the particles 21 to form an amorphous conductive carbon layer coated with SiO x Granular silicon-carbon composite material particles 2;

[0039] Step S02: Disperse the silicon-carbon composite material particles 2 in an organic solvent, add an organic solvent dissolved with one or at least two mixtures of asphalt, polymer materials or polymers, and carry out the mixing process. Spray drying treatment to obtain mixed powder;

[0040] Step S03: Carry out carbonization treatm...

Embodiment 1

[0062] This embodiment provides a SiO x / C composite negative electrode material and preparation method thereof.

[0063] It is prepared as follows:

[0064] S11. Select metal silicon powder with an average particle size of 4 μm and silicon dioxide powder with an average particle size of 20 nm as raw materials. The molar ratio of the selected metal silicon powder / silicon dioxide powder is 1:1, and put the two materials into water After fully stirring and mixing, put it in an oven at 120°C and dry it to make a cake-like material;

[0065] S12. Put the silicon and silicon dioxide mixed cake material into a sintering furnace with a low-pressure atmosphere and the temperature raised to 1400 ° C for 12 hours to obtain bulk SiO x (x=1) material;

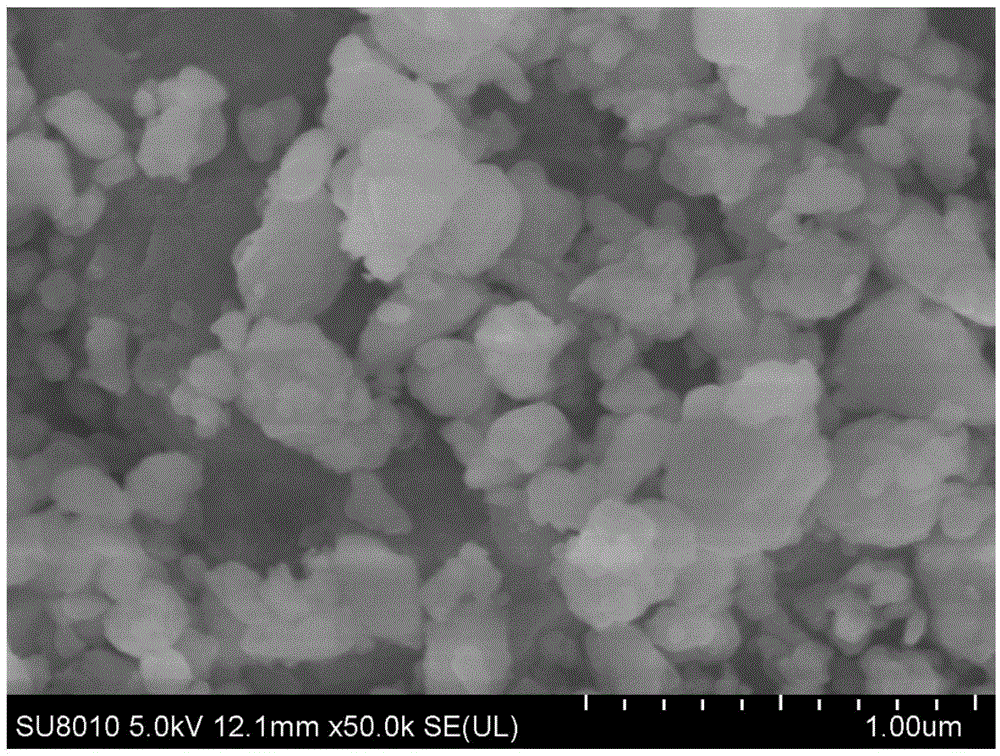

[0066] S13. SiO to be obtained x Put the bulk materials into the planetary ball mill and grind them for 6 hours, and then put them into the jet mill for 4 hours to get nano-sized SiO x Material;

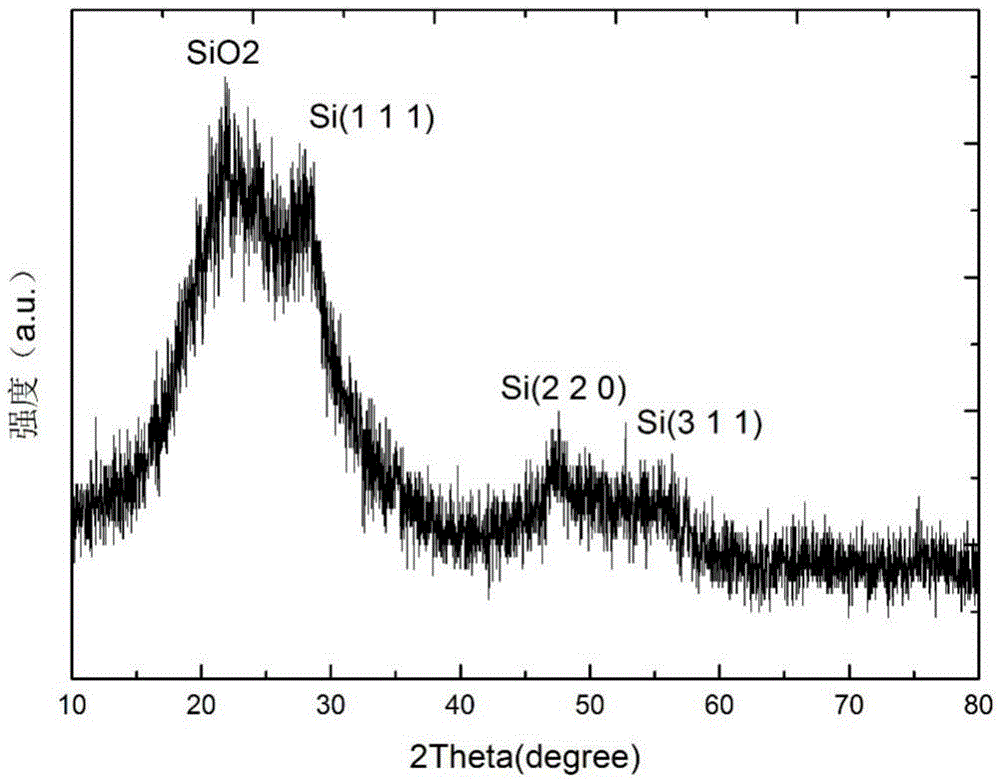

[0067] S14. the nano-SiO obtained in...

Embodiment 2

[0073] This embodiment provides a SiO x / C composite negative electrode material and preparation method thereof.

[0074] It is prepared as follows:

[0075] S21. Select metal silicon powder with an average particle size of 4 μm and silicon dioxide powder with an average particle size of 20 nm as raw materials. The molar ratio of the selected metal silicon powder / silicon dioxide powder is 1:3, and put the two materials into water After fully stirring and mixing, put it in an oven at 120°C and dry it to make a cake-like material;

[0076] S22. Put the silicon and silicon dioxide mixed cake material into a sintering furnace with a low-pressure atmosphere and the temperature raised to 1400 ° C for 12 hours to obtain bulk SiO x (x=1.5) material;

[0077] S23. SiO to be obtained x Put the bulk materials into the planetary ball mill and grind them for 6 hours, and then put them into the jet mill for 4 hours to get nano-sized SiO x Material;

[0078] S24. the nano-SiO obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com