Composite hard carbon cathode material of lithium ion battery and preparation method thereof

A lithium-ion battery and negative electrode material technology, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low initial charge and discharge efficiency, and achieve the effects of high rate, low production cost, and high initial coulombic efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

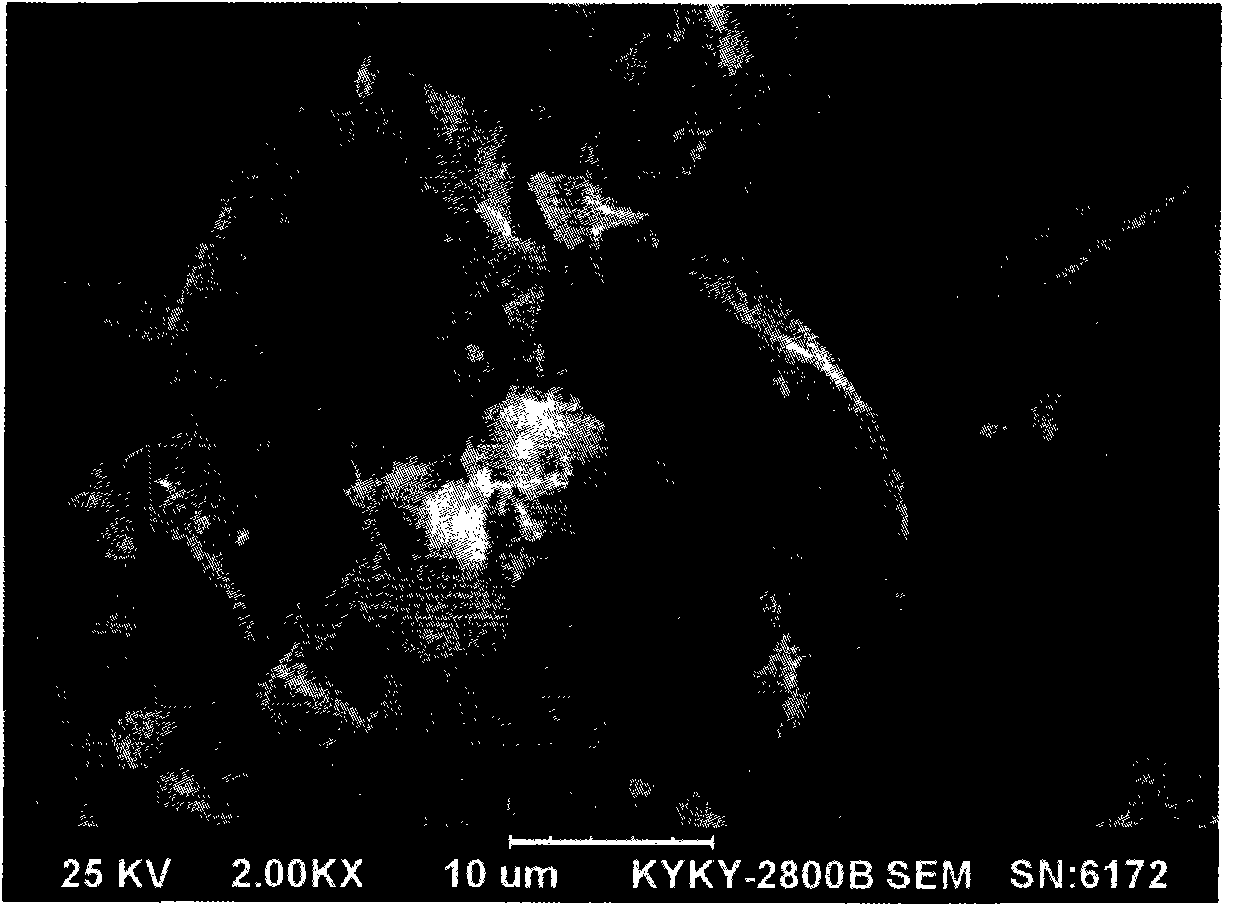

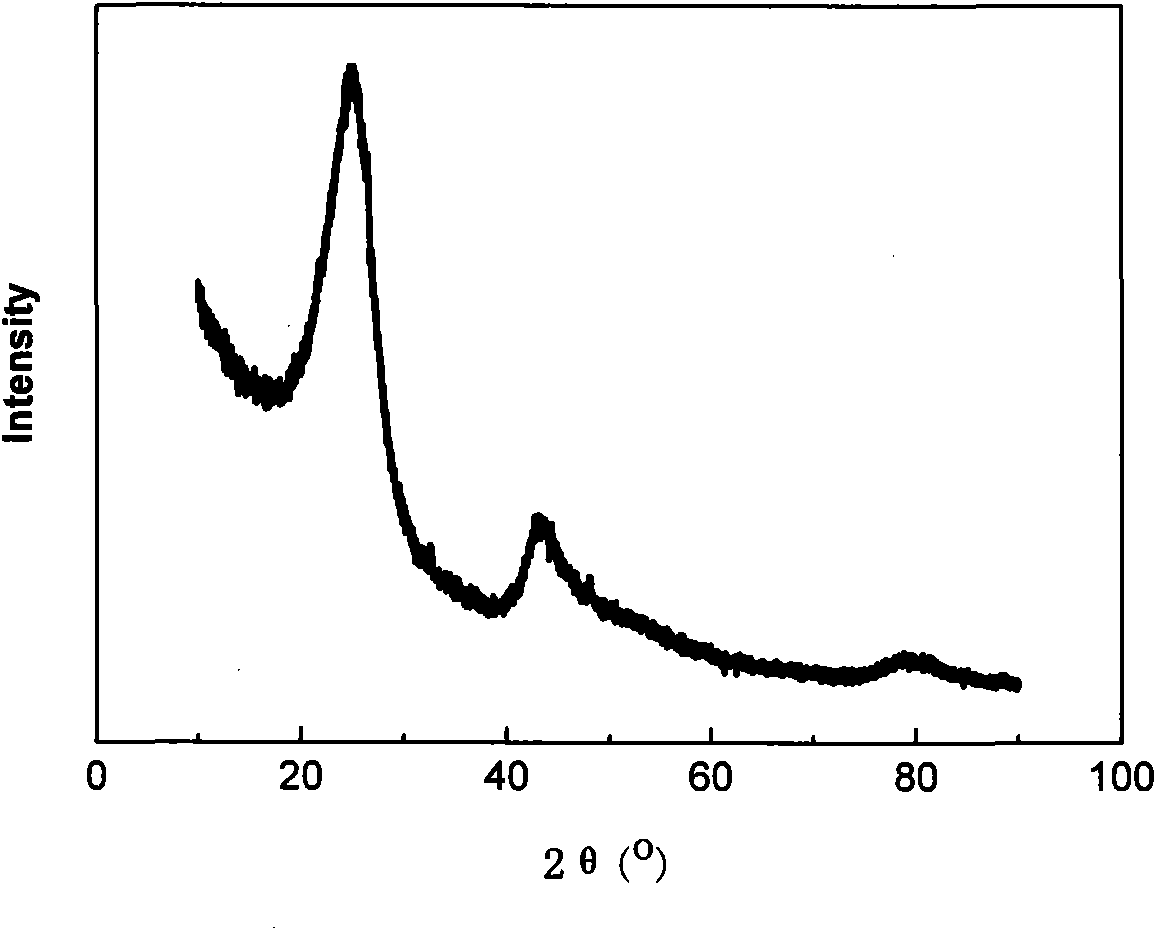

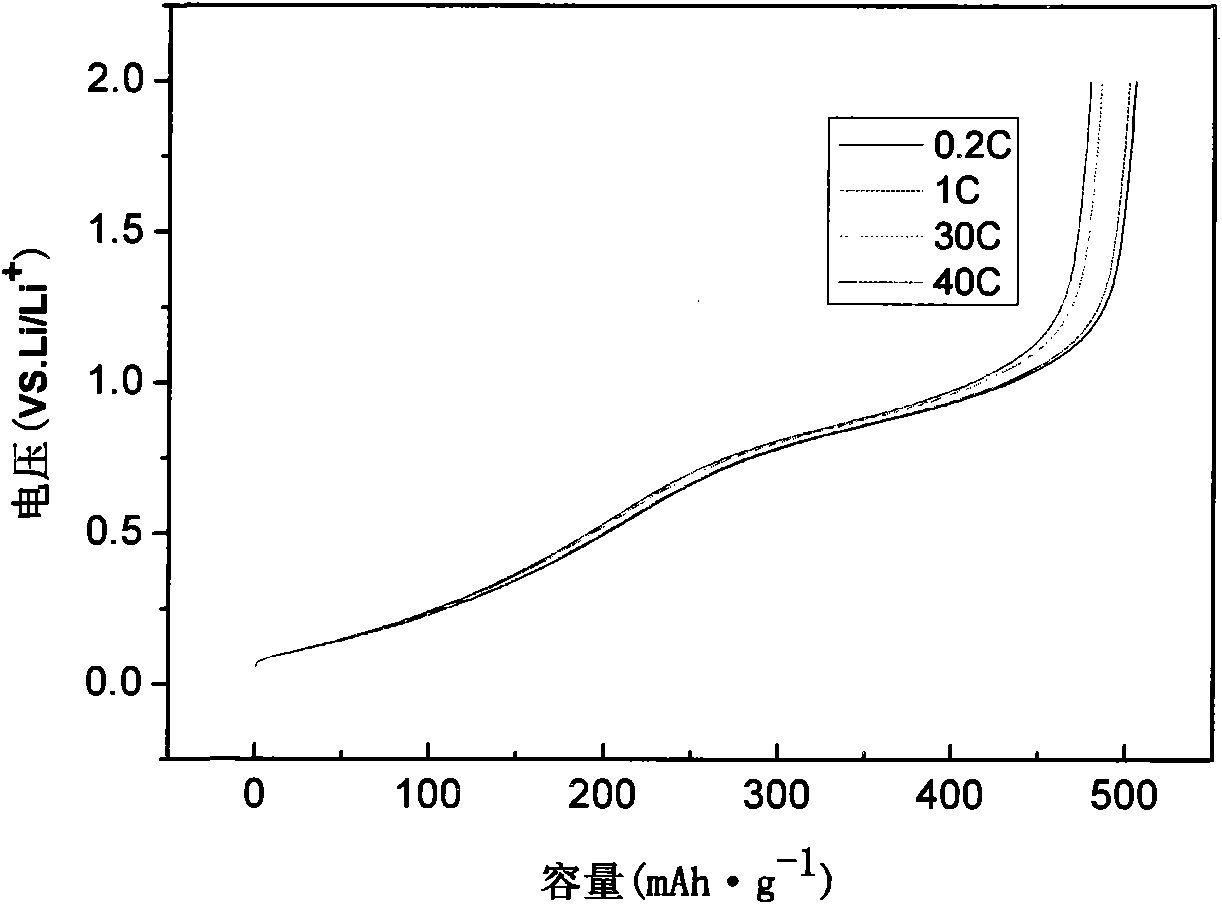

[0023] The present invention will be further described in detail below with reference to the drawings and embodiments. In the composite hard carbon negative electrode material of the lithium ion battery of the present invention, the hard carbon matrix is coated with a coating, which is formed by pyrolysis, and the mass of the precursor is 1-15% of the mass of the hard carbon matrix precursor.

[0024] The hard carbon matrix precursor is composed of the following mass ratios: 25% to less than 100% of thermoplastic resin (25%≤thermoplastic resin<100%), greater than 0 to less than 75% of curing agent (0<curing agent≤75 %), more than 0 to less than or equal to 15% of dopants (0<dopants≤15%), dopants are more than one kind of metal element, non-metal element, metal compound and non-metal compound, thermoplastic resin and After the curing agent is polymerized and chemically reacted, it is mixed with the dopant and then pyrolyzed to form a hard carbon matrix.

[0025] The hard carbon m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com