Pre-lithiation method of lithium ion battery negative electrode material

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, electrode carriers/collectors, non-aqueous electrolyte batteries, etc., can solve the problems of increased electrolyte viscosity, complex process, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

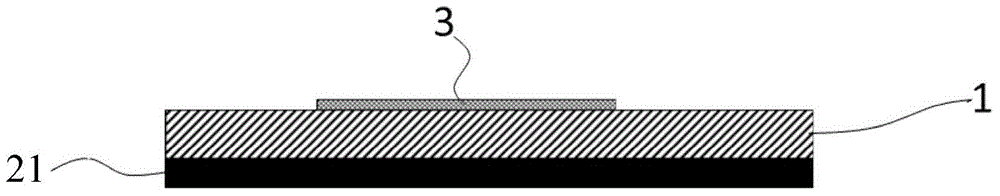

[0041] like figure 1As shown, a thin metal lithium layer with a thickness of 0.1 mm is embedded on the copper foil current collector 21, and then the copper foil current collector 22 coated with the negative electrode slurry 1 is passed through Cr with a resistance value of 1Ω. 20 Ni 80 The resistance wire is connected to the copper foil current collector 21, wherein the weight of the metal lithium thin layer is 10% of the weight of the silicon-silicon oxide-carbon composite negative electrode material, and then the above-mentioned processed negative electrode and positive electrode are assembled into a Lithium-ion battery, standing for 24 hours to activate.

Embodiment 2

[0043] like figure 2 As shown, a layer of copper foil is tightly wrapped on the surface of the 0.1mm metal lithium thin layer embedded and pressed on the copper foil current collector 21 as a lithium ion barrier layer, and two holes with a diameter of 0.5mm micropores, and then the copper foil current collector 22 coated with the negative electrode slurry 1 is connected to the copper foil current collector 21 through a copper wire with a resistance value R=0.005Ω, wherein the weight of the metal lithium thin layer 10% of the weight of the silicon-silicon oxide-carbon composite negative electrode material, and then assemble the above-mentioned negative electrode and positive electrode into a lithium-ion battery, and let it stand for activation for 24 hours.

Embodiment 3

[0045] A layer of paraffin wax is tightly wrapped on the surface of the metal lithium thin layer 3 with a thickness of 0.1 mm embedded on the copper foil current collector 21 as a lithium ion barrier layer, and a microscopic hole with a pore size of 0.2 mm is punctured on the paraffin wax as the barrier layer. hole, and then the copper foil current collector 22 coated with the negative electrode slurry 1 is connected to the copper foil current collector 21 through a copper wire with a resistance value R=0.005Ω, wherein the weight of the metal lithium thin layer is silicon-silicon 10% by weight of the oxide-carbon composite negative electrode material, and then assemble the above-mentioned negative electrode and positive electrode into a lithium-ion battery, and leave it to activate for 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com