Torispherical cathode material for lithium ion battery and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, circuits, electrical components, etc., can solve problems such as the rate performance of graphite materials that are not involved, and achieve the effects of improving high rate performance, improving the first Coulomb efficiency, and shortening the diffusion path.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

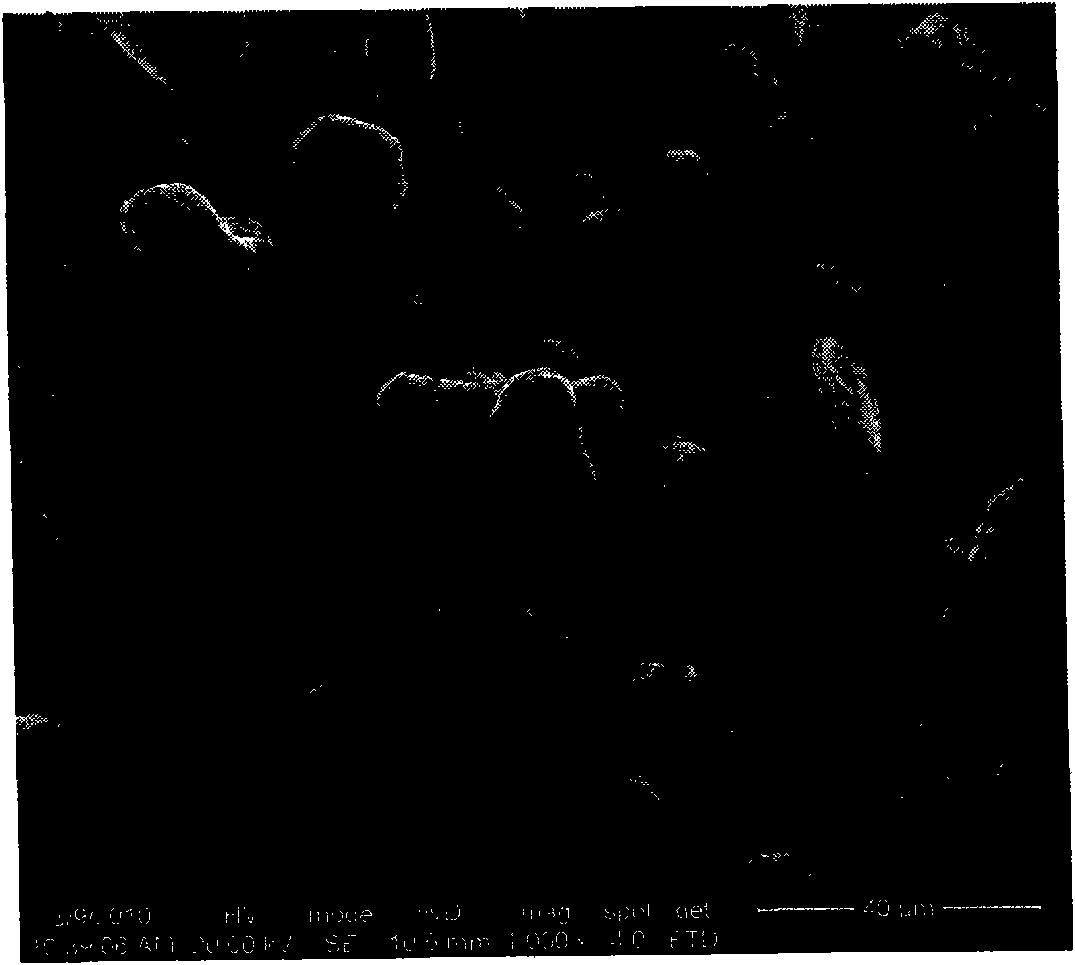

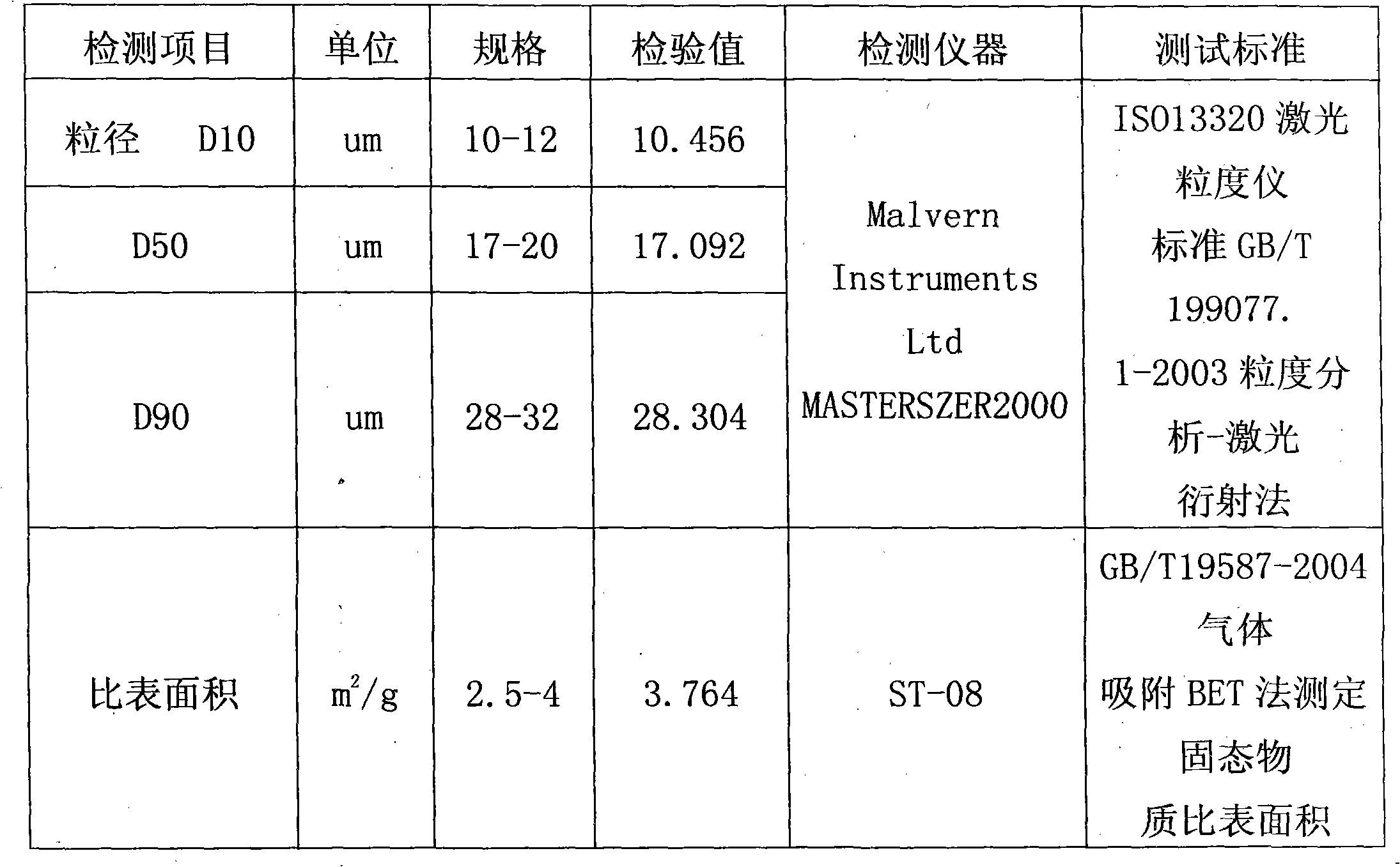

[0017] 1. Crush 50kg of spherical artificial graphite through a pulverizer, and the pulverized artificial graphite D50: 17-20um.

[0018] 2. Add the pulverized and shaped artificial graphite to pitch coke and pore former. The proportion of artificial graphite, silicon powder and pitch coke is 100:5:10. Stir uniformly at 210°C, and the mixing time is 2h.

[0019] 3. Then the uniformly stirred materials are carbonized under nitrogen protection at 900°C for 5h.

[0020] 4. The carbonized material is sent to a high temperature furnace at 2600°C and graphitized under the protection of nitrogen.

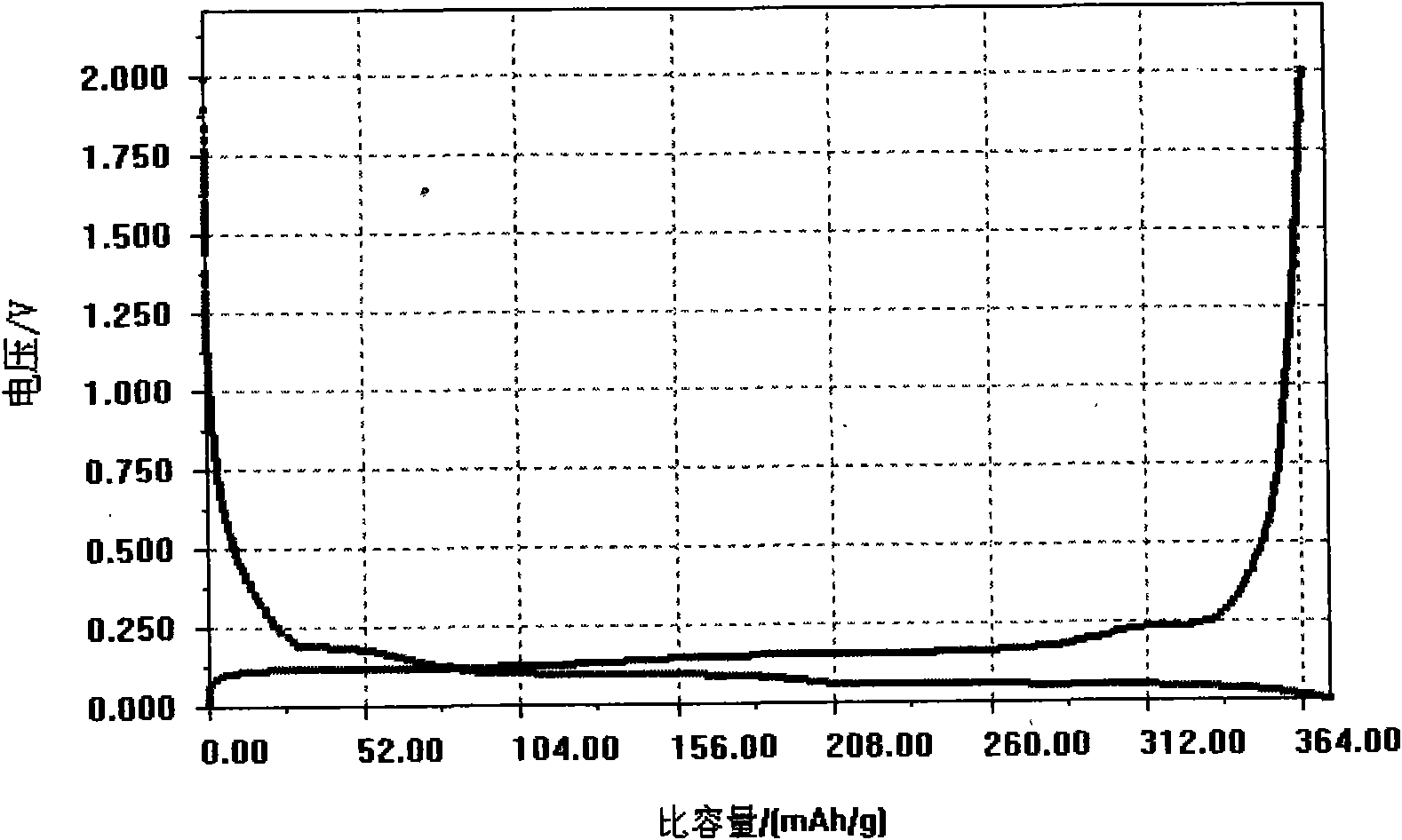

[0021] 5. Production and testing of button batteries

[0022] 1) Electrolyte: 1M-LiPF6 EC / DMC / EMC

[0023] 2), Binder: LA-133: 3%

[0024] 3) Conductive agent: Super-P: 3%

[0025] 4) Counter electrode: pure lithium sheet

[0026] 5), charge and discharge system

[0027] (A) Constant current discharge (0.2mA, 0.001V)

[0028] (B) Let stand (1min)

[0029] (C) Constant current charging (0.2mA, 2.000V)

[003...

Embodiment 2

[0032] 1. The 50kg spherical natural graphite: spherical artificial graphite weight ratio 1:1 mixed raw materials are crushed by a crusher, and the crushed artificial graphite D50: 17-20um.

[0033] 2. Add the pulverized and shaped mixed raw materials into pitch coke and pore-forming agent. The proportion of artificial graphite, silicon powder and pitch coke is 100:2:15. Stir uniformly at 260°C, and the mixing time is 2 hours.

[0034] 3. Then the uniformly stirred materials are carbonized under nitrogen protection at 900°C for 6 hours.

[0035] 4. The carbonized material is sent to a high temperature furnace at 2600°C and graphitized under the protection of nitrogen.

[0036] 5. Production and testing of button batteries

[0037] 1) Electrolyte: 1M-LiPF6 EC / DMC / EMC

[0038] 2), Binder: LA-133: 3%

[0039] 3) Conductive agent: Super-P: 3%

[0040] 4) Counter electrode: pure lithium sheet

[0041] 5), charge and discharge system

[0042] (A) Constant current discharge (0.2mA, 0.001V)

[0043] ...

Embodiment 3

[0047] 1. The 50kg mesocarbon microspheres are crushed by a pulverizer, and the pulverized artificial graphite D50: 17-20um.

[0048] 2. Add the pulverized and shaped mesocarbon microspheres into pitch coke and pore-forming agent. The proportion of artificial graphite, silicon powder and pitch coke is 100:5:10. Stir uniformly at 230°C and the mixing time is 2h.

[0049] 3. Then the uniformly stirred materials are carbonized under nitrogen protection at 900°C for 5 hours.

[0050] 4. The carbonized material is sent to a high temperature furnace at 2600°C and graphitized under the protection of nitrogen.

[0051] 5. Production and testing of button batteries

[0052] 1) Electrolyte: 1M-LiPF6 EC / DMC / EMC

[0053] 2), Binder: LA-133: 3%

[0054] 3) Conductive agent: Super-P: 3%

[0055] 4) Counter electrode: pure lithium sheet

[0056] 5), charge and discharge system

[0057] (A) Constant current discharge (0.2mA, 0.001V)

[0058] (B) Let stand (1min)

[0059] (C) Constant current charging (0.2mA, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture range | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com